Coal bed gas thermal production increasing method

A coalbed methane and thermal recovery technology, which is applied in the fields of mining fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of coal powder blocking the channel, damage to the original structure of the coal seam, low water saturation, etc., and reduce the number of abandoned wells. production, cost reduction, and yield enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

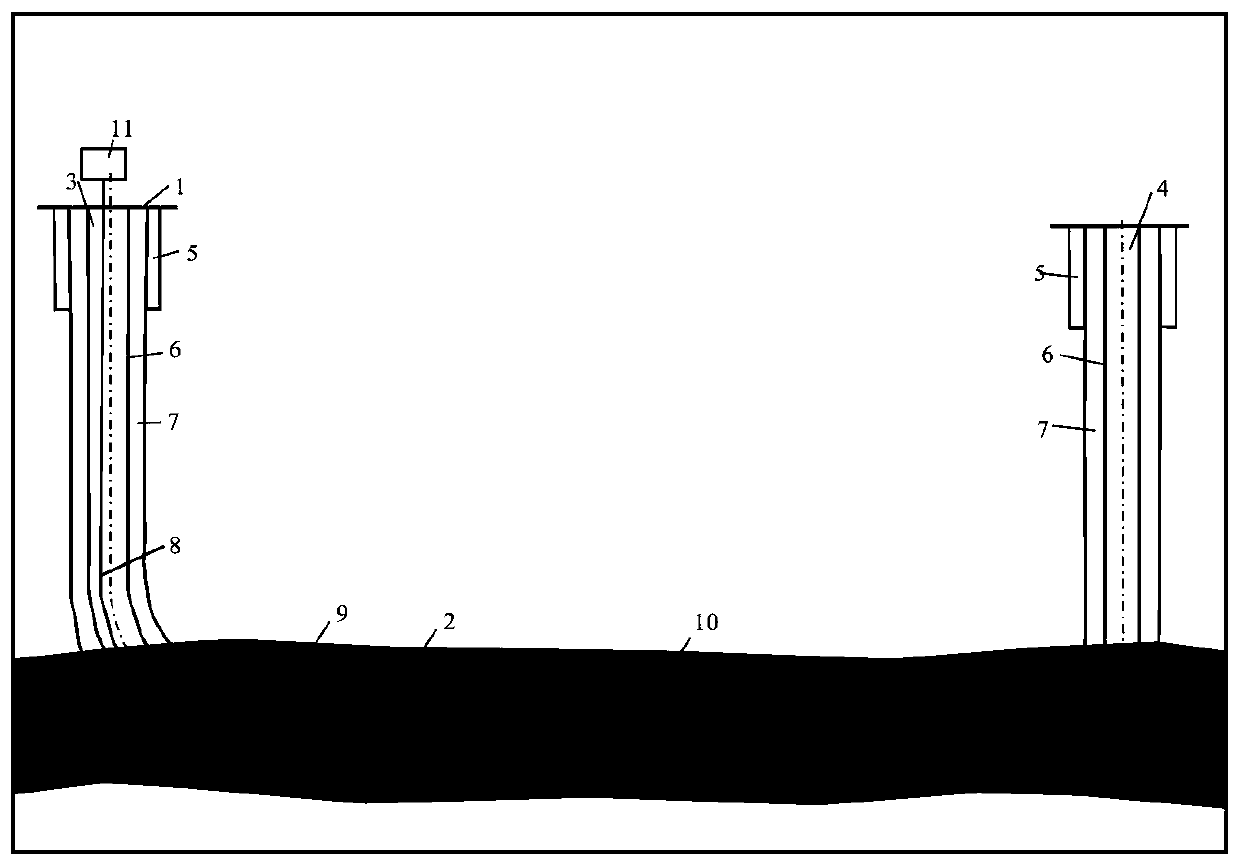

[0029] Such as figure 1 Firstly, the directional drilling / drainage difficult directional well is obtained by directional drilling technology, one of the drilling holes (injection well 3) is drilled into the coal seam 2, and the vertical production well 4 passes through the horizontal section screen 10 and the coal seam The injection well 3 is connected to form a continuous gasification channel.

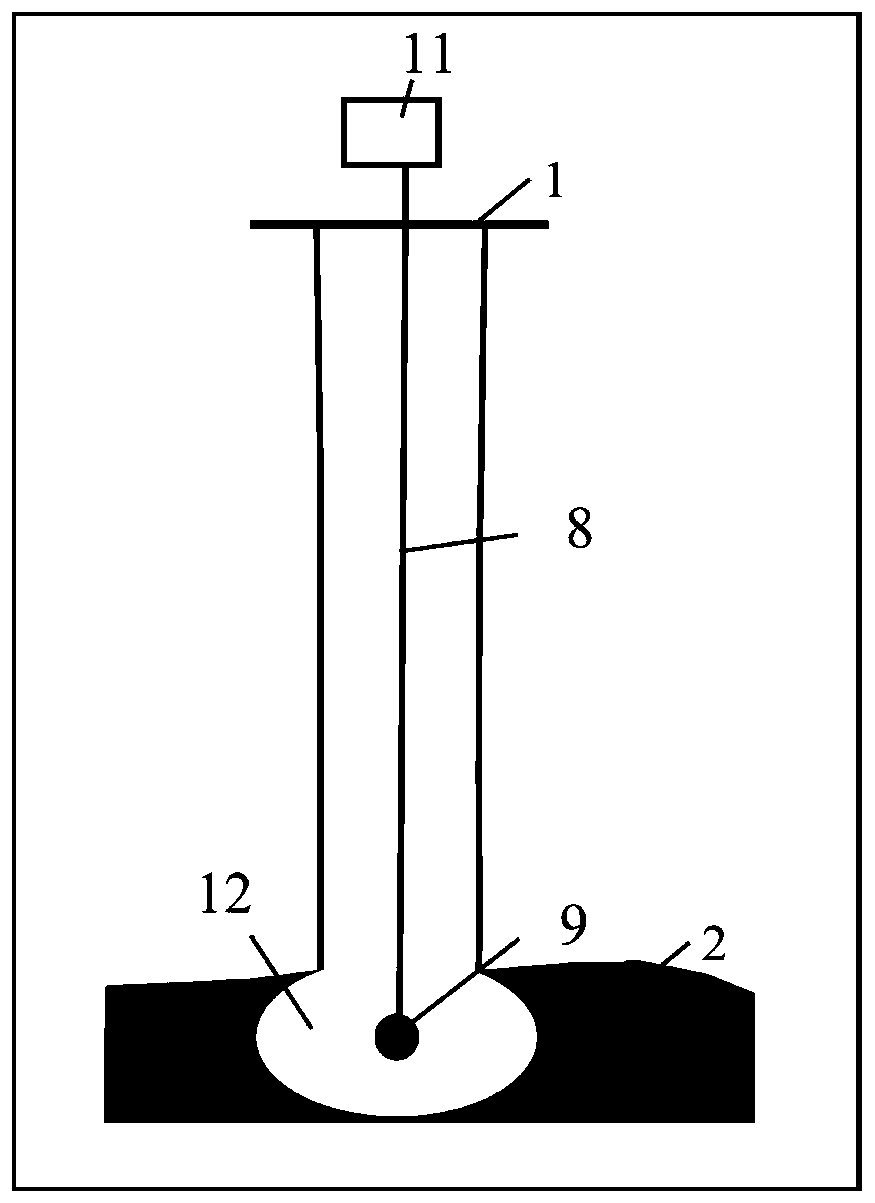

[0030] Firstly, the concentric casing 6 is installed to provide passages for gas production, gas injection, gas cleaning and cooling water flow. The concentric casing 6 is provided with a serpentine tube 8 for controlling the controlled retreat injection point (CRIP). When specifically controlling, the bottom end of the serpentine tube 8 is provided with a movable nozzle and an igniter 9 both facing a specific area of the coal seam, wherein the movable nozzle is used to spray gasification agents, namely oxygen and water. The bottom end of the serpentine pipe 8 adjusts the coal burn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com