Horizontal bare hole flow guiding slot well and method for mining coal bed gas of sugarcoated haw well

A horizontal open-hole and diversion groove technology, which is applied in the fields of production fluids, wellbore/well components, and earth-moving drilling, etc., can solve the problems of collapse and blockage of wellbore maintenance, difficulty in maintenance of wellbore, buried drainage pipe string, and inability to strengthen and reform coal seam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

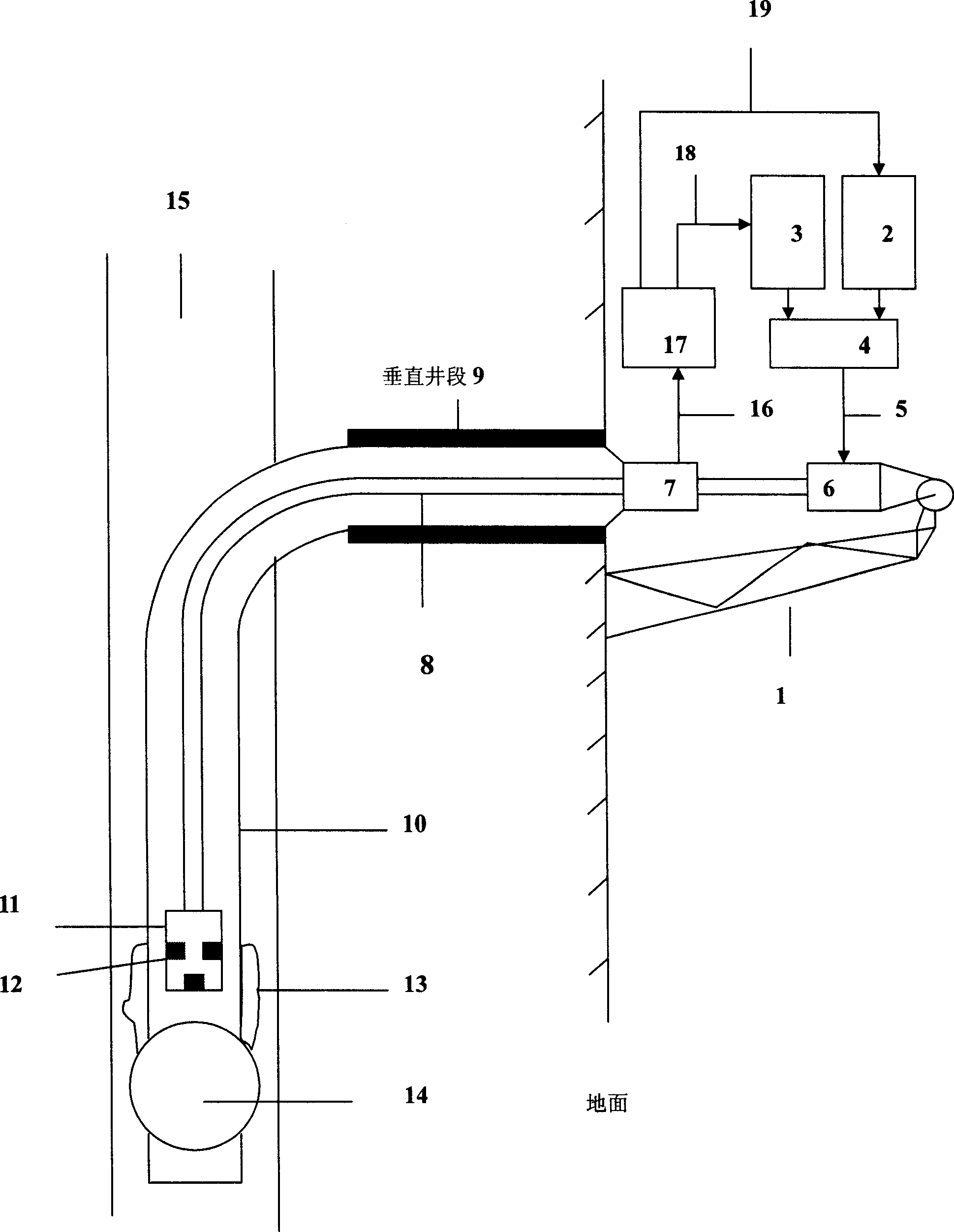

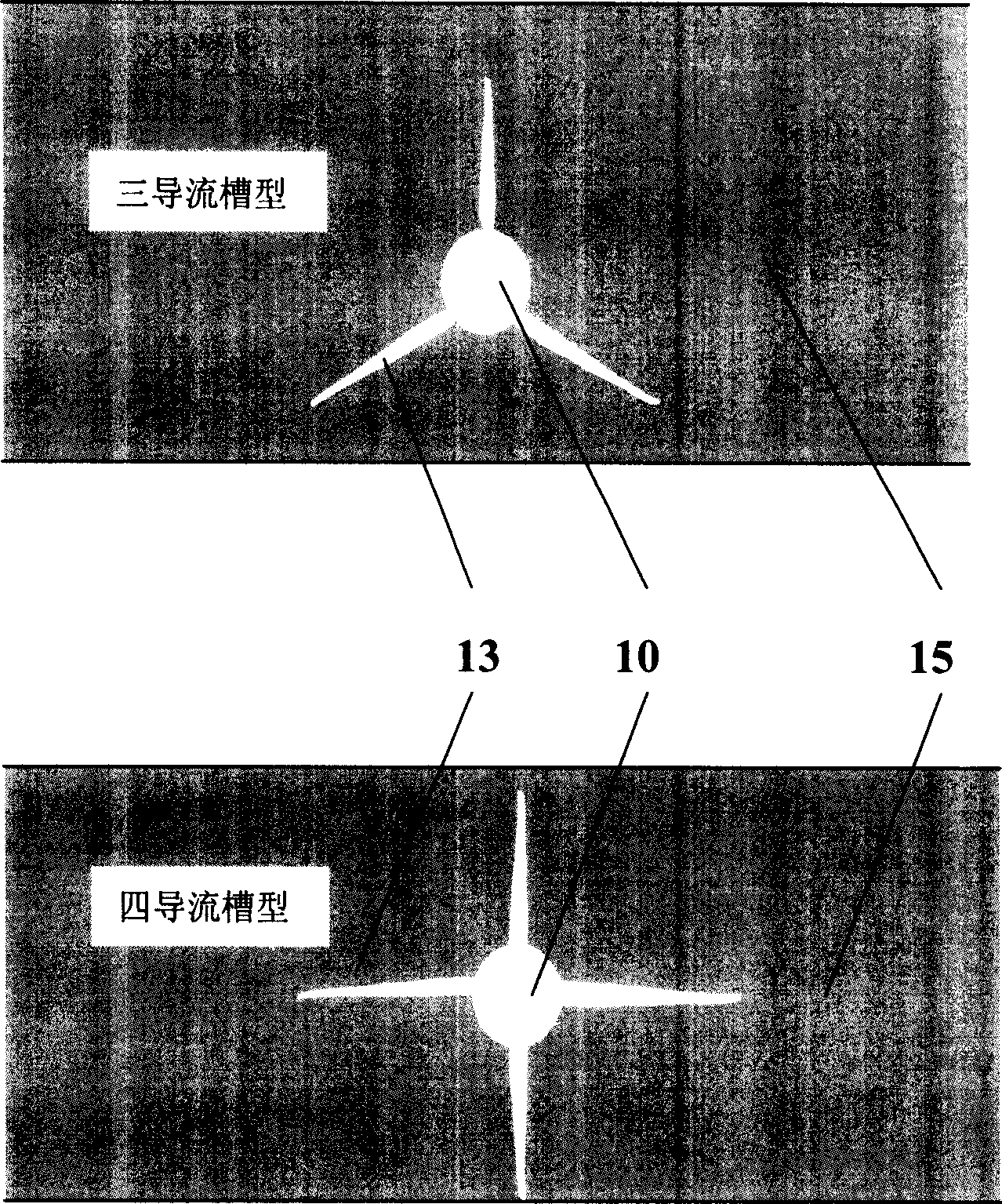

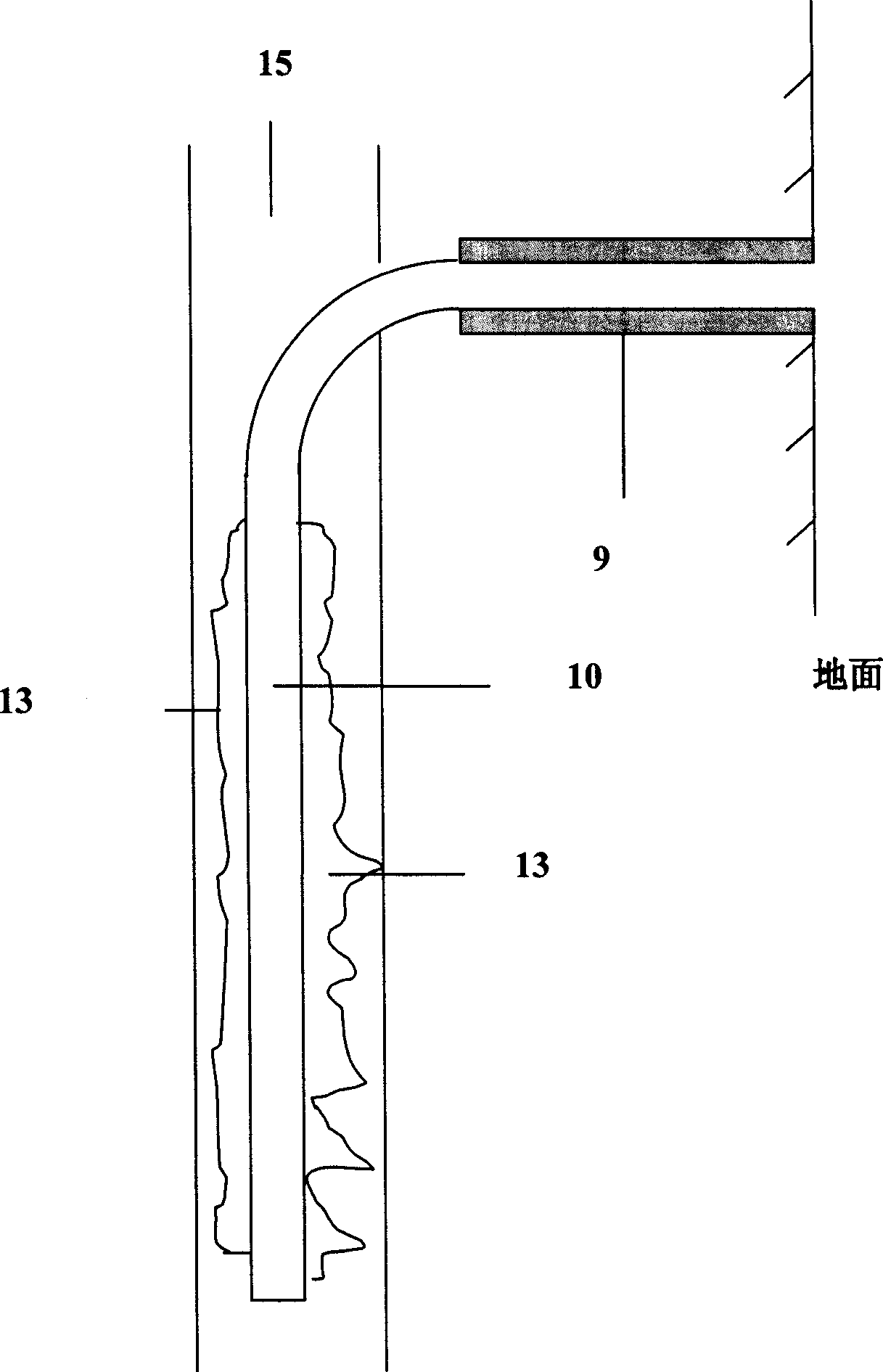

[0017] Such as figure 1 As shown, the cutting of the high-pressure air-water mixture fluid is carried out by the surface pump train group 2 and the air compression supercharger train group 3 with a certain displacement and a certain proportion of the air-water mixture 5 under certain high-pressure conditions. The surface manifold system 4 is injected into the downhole working string that moves back and forth—the tubing 8 or the coiled tubing 8 with the fluid cutting gun 11 . Due to the throttling effect of the nozzle 12 of the cutting gun 11, a pressure difference of 15-20 MPa is formed inside and outside the cutting gun 11, and the high-pressure gas-water mixed flow 5 ejected by the spray gun 11 has a strong cutting effect on the coal seam 15 around the wellbore 10 , under the continuous action of this fluid cutting operation, diversion grooves 13 and fluid cutting caves 14 can be formed in the coal seam 15 around the wellbore 10 . At the same time, the coal chips cut from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com