Coal bed gas horizontal well track control method

A trajectory control, horizontal well technology, applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve the problems of increased wear resistance of drilling tools, difficult construction, difficult reentry, etc., to achieve improved water drainage and gas recovery , the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

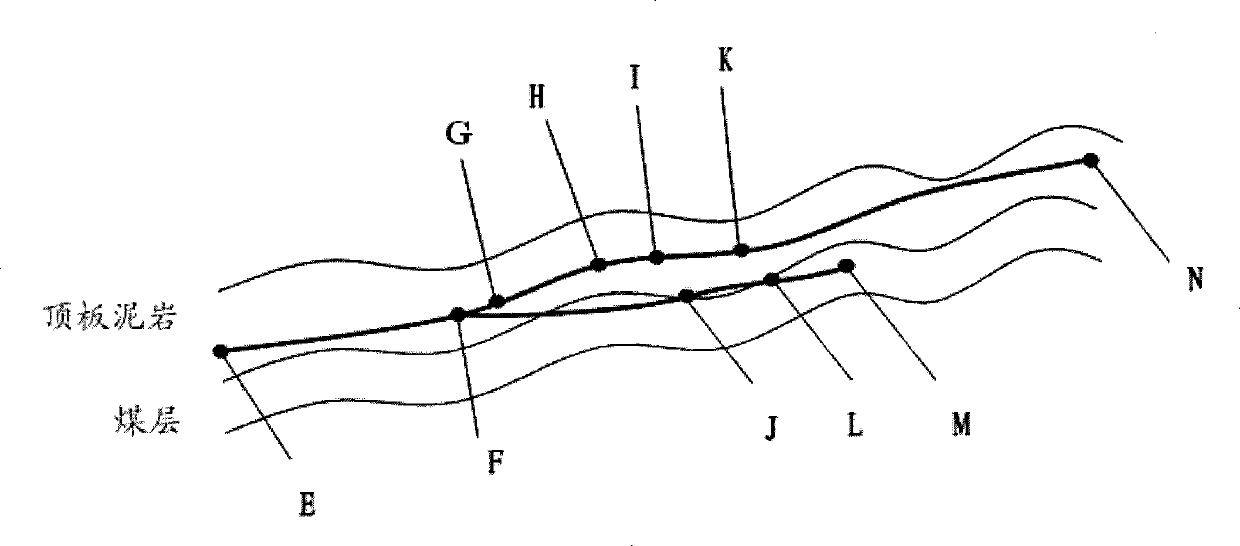

[0018] Below in conjunction with specific embodiment, the present invention will be further described, appended figure 2 It can be used as a schematic diagram of the trajectory control of the roof rock layer construction in this embodiment.

[0019] According to the regional seismic data and the drilled well data, the monocline structure area with formation occurrence of 2°-7° is selected to deploy multi-branch horizontal wells, and the main and sub-wellbores are designed to extend along the updip direction of the formation. The main branch trajectory of the implemented multi-branch horizontal well is in the coal seam roof rock formation, and the branches enter the coal seam through lateral drilling and extend in the coal seam.

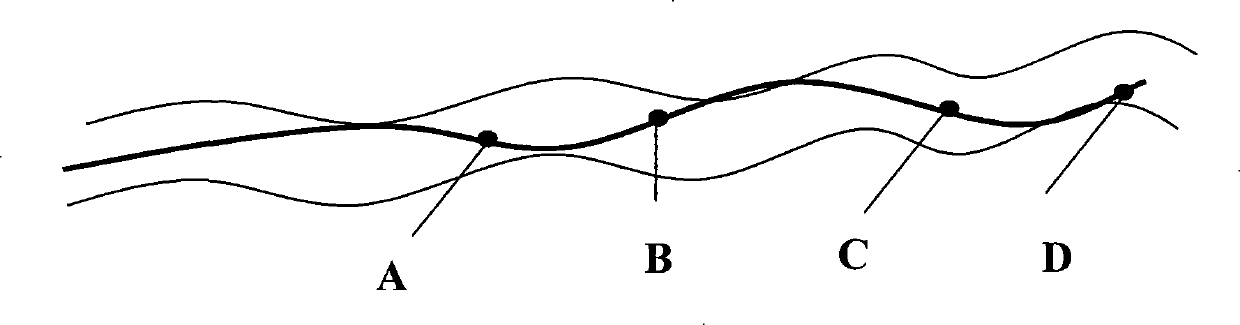

[0020] In order to ensure that the drilled main branch and branch boreholes are always up-dipping, and the inclination angle is greater than 90.5°, the designed horizontal wellbore trajectory starts at the low-dip position of the coal seam and ends a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com