Method for production increasing of coal-bed gas through combination of heat injection decomposition and microbial degradation

A microbial degradation and biodegradation technology is applied in the field of coalbed methane mining, which can solve the problems of low coalbed gas permeability and low coalbed methane recovery rate, and achieve the goal of improving the recovery rate, adapting to the high temperature environment of the coalbed, and improving the permeability of the coalbed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

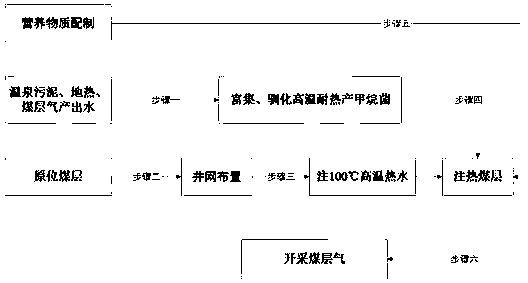

[0032] A method for increasing the production of coalbed methane by injecting thermal decomposition and microbial degradation, the specific steps of the method are as follows:

[0033] a) Collect hot spring sludge samples, put them in an incubator and quickly transport them back to the laboratory, use coal as the only carbon source, and provide nutrients at the same time, enrich and domesticate high-temperature heat-resistant methanogenic bacteria in the laboratory. Taking the amount of methane produced per unit mass of coal and the rate of methane production as indicators, through repeated transfer, cultivation, and domestication to obtain high-efficiency high-temperature heat-resistant methanogenic bacteria, which can fully adapt to 65°C coal seams;

[0034] b) According to the geological characteristics and existing construction technology, vertical drilling is carried out from the ground, the well pattern is arranged, the well depth reaches the coal seam, and 5 vertical wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com