Copper-molybdenum ore pre-enrichment method.

A pre-enrichment and copper-molybdenum ore technology, applied in grain processing, etc., can solve the problems of low copper and molybdenum content, high equipment load rate, and difficult sorting, so as to improve the quality content, exert processing capacity, and reduce The effect of beneficiation materials and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

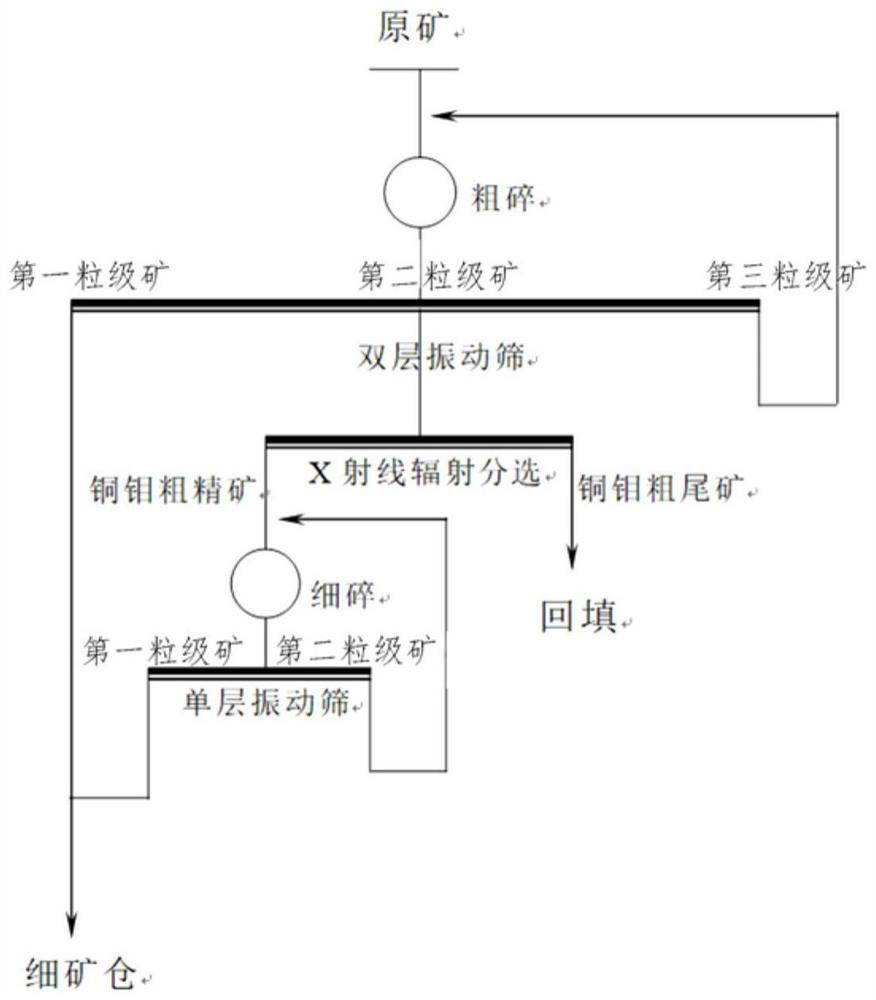

[0039] The daily processing capacity of the copper-molybdenum raw ore in the present embodiment is 1500t, and the mass content of copper is 0.45% in the copper-molybdenum raw ore, and the mass content of molybdenum is 0.020%; figure 2 As shown, this embodiment includes the following steps:

[0040] Step 1. Send the copper-molybdenum ore with a particle size of 0-360mm into a first-stage jaw crusher for crushing, and then sieve through a double-layer vibrating screen to obtain a particle size of less than 15mm ore, a particle size greater than 15mm and Grain-sized ore with a particle size smaller than 45mm and particle-sized ore with a particle size larger than 45mm;

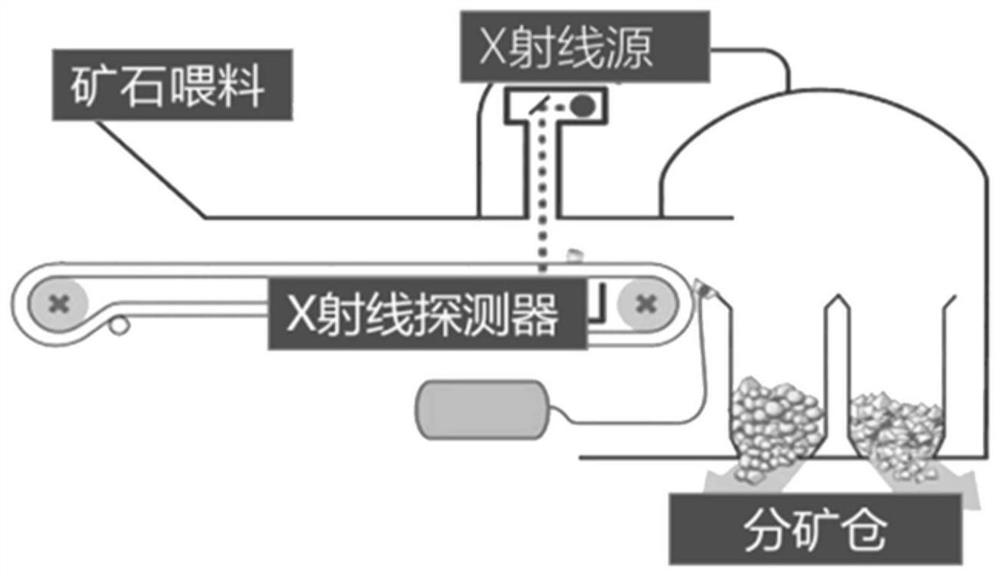

[0041] Step 2. Return the ore with a particle size greater than 45mm obtained in step 1 to the jaw crusher in step 1 to continue crushing, and vibrate the ore with a particle size greater than 15mm and less than 45mm obtained in step 1. The feeder is sent to the X-ray radiation sorter for sorting to obtain copp...

Embodiment 2

[0048] The daily processing capacity of the copper-molybdenum raw ore in the present embodiment is 2500t, and the mass content of copper is 0.20% in the copper-molybdenum raw ore, and the mass content of molybdenum is 0.012%; figure 2 As shown, this embodiment includes the following steps:

[0049] Step 1. Send the copper-molybdenum ore with a particle size of 0-300mm into a first-stage jaw crusher for crushing, and then sieve through a double-layer vibrating screen to obtain a particle size of less than 15mm ore, a particle size greater than 15mm and Grain-sized ore with a particle size smaller than 45mm and particle-sized ore with a particle size larger than 45mm;

[0050] Step 2. Return the ore with a particle size greater than 45mm obtained in step 1 to the jaw crusher in step 1 to continue crushing, and process the ore with a particle size greater than 15mm and less than 45mm obtained in step 1. The vibrating feeder is fed into the X-ray radiation separator for sorting ...

Embodiment 3

[0057] The daily processing capacity of the copper-molybdenum raw ore in the present embodiment is 1200t, and the mass content of copper is 1.20% in the copper-molybdenum raw ore, and the mass content of molybdenum is 0.092%; figure 2 As shown, this embodiment includes the following steps:

[0058] Step 1. Send the copper-molybdenum raw ore with a particle size of 0-280mm into a first-stage jaw crusher for crushing, and then sieve through a double-layer vibrating screen to obtain a particle size of less than 15mm ore, a particle size greater than 15mm and Ores with a particle size of less than 45mm and ores with a particle size greater than 45mm;

[0059] Step 2. Return the ore with a particle size greater than 45mm obtained in step 1 to the jaw crusher in step 1 to continue crushing, and vibrate the ore with a particle size greater than 15mm and less than 45mm obtained in step 1. The feeder is sent to the X-ray radiation sorter for sorting to obtain copper-molybdenum rough ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com