Rectifying device of vehicle AC generator

A technology for alternators and rectifiers, applied in electromechanical devices, cooling/ventilation devices, electrical components, etc., can solve the problems of cooling function decline, solder flow, poor cooling performance, etc., to prevent damage and prevent solder flow , The effect of reducing the manpower required for assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings.

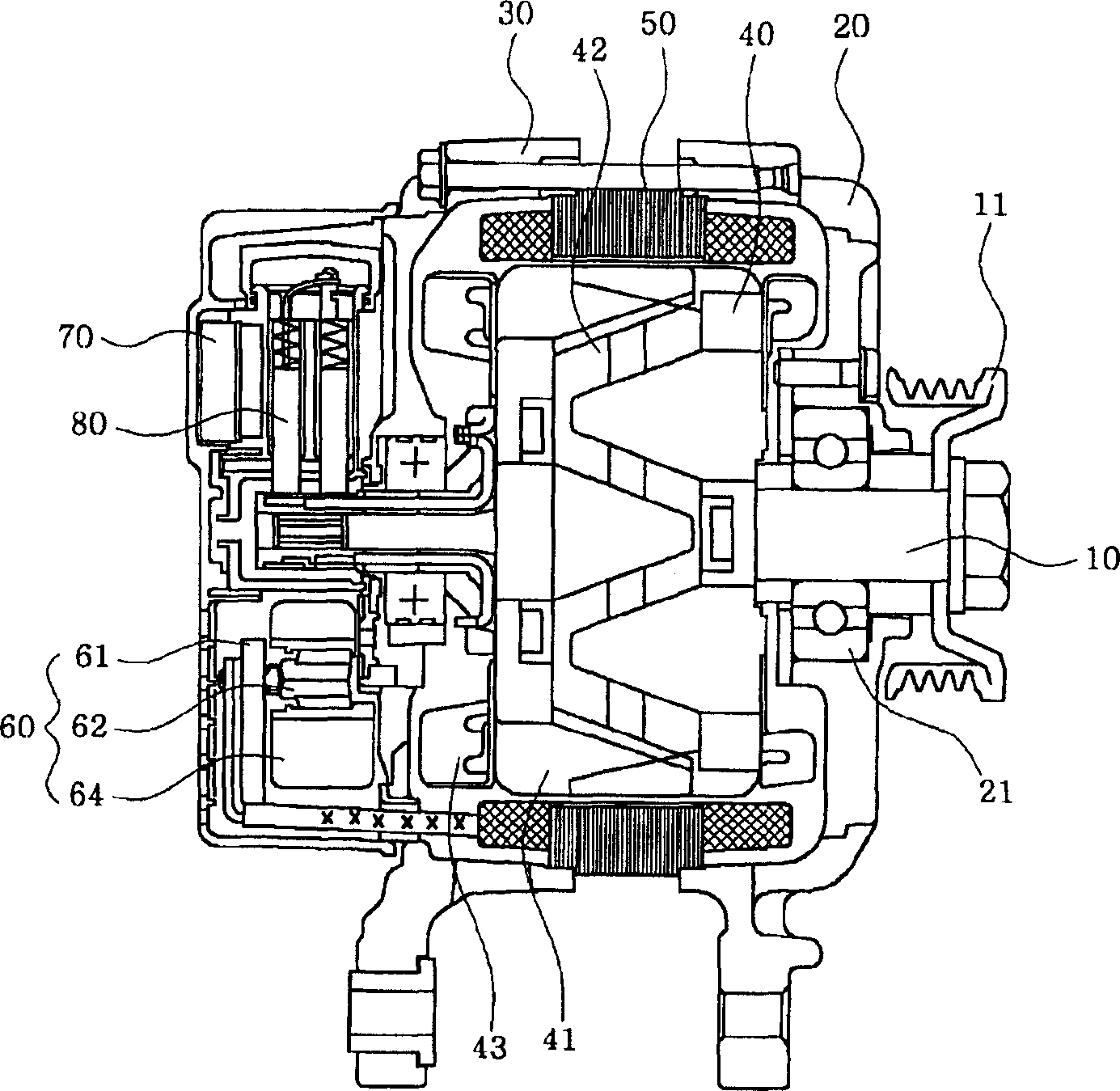

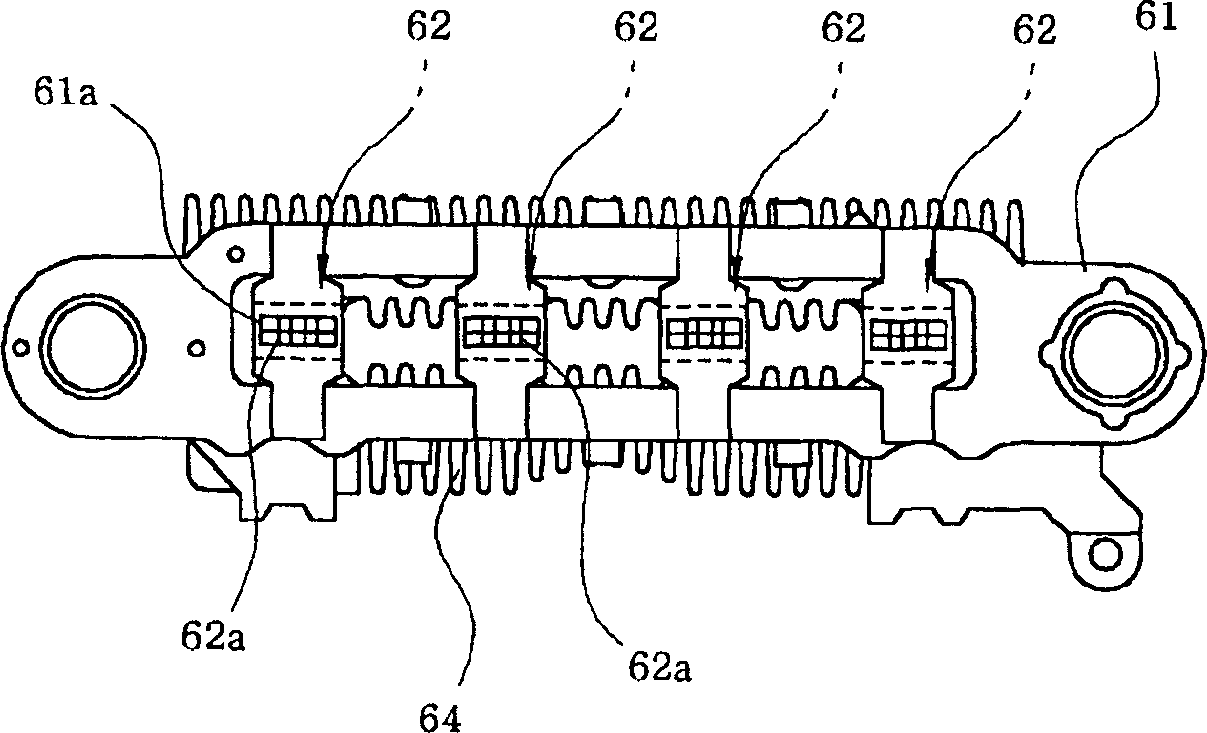

[0022] Figure 4 To show a side view of an alternator according to an embodiment of the present invention, Figure 5 It is a structural diagram of the rectifying device of the present invention.

[0023] First of all, the alternator using the rectifying device 60 of the present invention is also compatible with figure 1 As shown, the rotating shaft 10 supported by the respective bearings 21 at the center of the front bracket 20 and the rear bracket 30 in the state fixed to the end thereof by the pulley 11 is installed in the middle section of the rotating shaft and includes a magnetic field core 41 and the rotor device 40 with the coil 42 wound inside it, and the stator 50 surrounding the rotor device in a state fixed between the front bracket 20 and the rear bracket 30, and in the rear bracket The rectifying device 60 , the voltage regulator 70 and the brush suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com