Comprehensive coal milling device for coal mine

A coal mining device and coal mine technology, applied in the direction of earth drilling, spring/shock absorber, slitting machinery, etc., can solve the health hazards of coal miners and other problems, to ensure health, avoid damage, and reduce coal dust content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

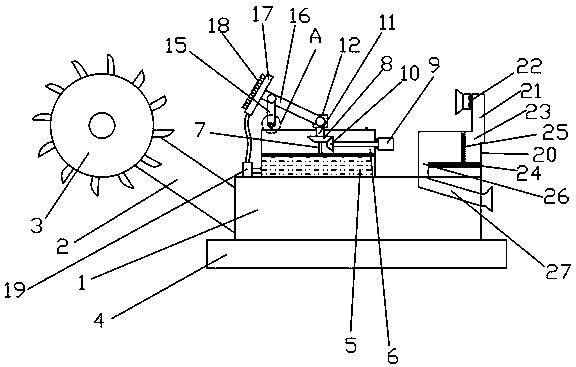

[0029] Such as figure 1 and figure 2 As shown, a comprehensive coal mining device for coal mines provided in this embodiment includes a body 1, a cutting arm 2 is provided on one side of the body 1, and a cutting drum 3 is rotatably connected to the end of the cutting arm 2. The bottom of the body 1 is provided with a base 4, and the top of the body 1 is provided with a first dust-reducing mechanism and a second dust-reducing mechanism. The first dust-reducing mechanism includes a water tank 5 and a functional box 6 located above the water tank 6. There is an installation shaft 7, on which a first bevel gear 8 is rotatably connected, and a first motor 9 is arranged outside the function box 6, and the output shaft of the first motor 9 extends into the function box 6 and is connected with a The second bevel gear 10, the second bevel gear 10 meshes with the first bevel gear 8, the upper end of the first bevel gear 8 is fixedly connected with a rotating shaft 11, and the upper e...

Embodiment 2

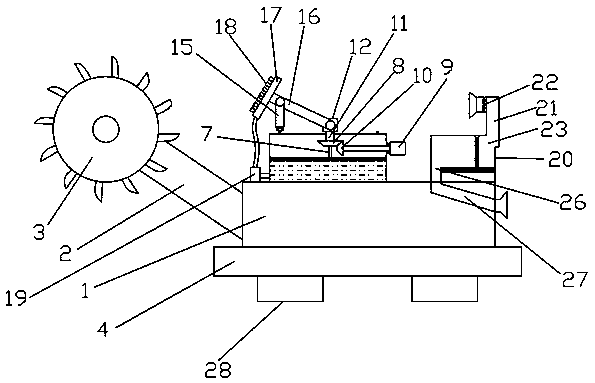

[0033] Such as image 3 and Figure 4As shown, the comprehensive coal mining device for coal mine provided by this embodiment has the same general structure as that of Embodiment 1, but in order to improve the shock absorption effect of the device, two shock absorbing mechanisms are provided under the base 4, each The shock-absorbing mechanism comprises a shock-absorbing housing 28, and two sliding posts 29 are arranged in the shock-absorbing case 28, and a first shock-absorbing rod 30 is slidably connected between the two sliding posts 29, and the first shock-absorbing rod 30 is fixed There is a supporting foot 31 extending out of the shock-absorbing shell 28, the upper end of the supporting foot 31 is fixedly connected with the base 4, and a first shock-absorbing spring 32 is sleeved on each sliding column 29, and the first shock-absorbing spring The lower end of 32 is connected with the first damping rod 30, a second connecting block 33 is arranged below the first damping ...

Embodiment 3

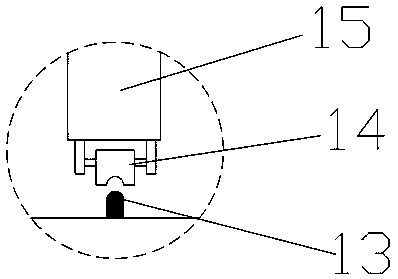

[0036] Such as Figure 5 and Figure 6 As shown, the comprehensive coal mining device for coal mine provided by this embodiment has the same general structure as that of Embodiment 2, but in order to realize the adjustment of the first spray pipe in the vertical direction, a roller 14 is provided above Lifting mechanism, the lifting mechanism includes a first cylinder 38 , the telescopic rod of the first cylinder 38 is connected with the connecting rod 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com