Low-cost combined hydrofinishing method

A technology of hydrofining and process method, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, which can solve the problems of reducing reaction efficiency, not completely removing harmful impurities, and not being able to effectively handle sulfur, etc., to achieve improved Reaction efficiency, improvement of effective utilization efficiency, and effect of eliminating the influence of wetting factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

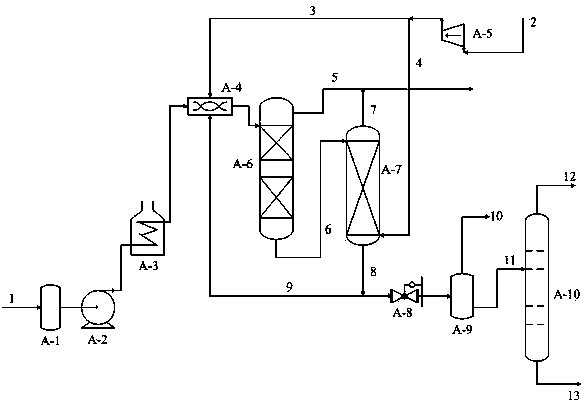

[0029] press figure 1 The operation process of the liquid phase circulating hydrogenation reactor and the gas-liquid countercurrent hydrogenation reactor are used in series. The normal third-line diesel (sulfur content 18000μg / g) is used as raw material for hydrofining and desulfurization. The catalyst is FHUDS-5 catalyst developed and produced by Fushun Petrochemical Research Institute. First, the theoretical dissolved hydrogen amount of the reaction system (0.11 wt%) is tested and determined, and then the process of the method of the present invention is carried out. The reaction pressure of liquid phase hydrogenation is 5.0MPa, the reaction temperature is 350℃, and the volumetric space velocity of the fresh raw oil is 4.0h. -1 . The amount of hydrogen mixed in the fixed control oil is 0.12wt% (hydrogen mixing amount / feeding amount, that is, the mixing amount of hydrogen is 1.09 times the saturated dissolved amount of the reaction state), and it is a constant amount, and the...

Embodiment 2

[0037] press figure 1 As shown in the process flow, a liquid-phase circulating hydrogenation reactor and a gas-liquid countercurrent hydrogenation reactor are used in series. Using mixed diesel raw materials (normal third-line straight-run diesel mixed with 30v% catalytic diesel) as raw materials (sulfur content of 13000μg / g, nitrogen content of 550μg / g) for hydrorefining and desulfurization, the catalyst is FHUDS developed and produced by Fushun Petrochemical Research Institute -2 Catalyst. First, the theoretical dissolved hydrogen amount of the reaction system (0.14wt%) is tested and determined, and then the process of the method of the invention is carried out. The pressure of the liquid phase hydrogenation reaction is 6.5MPa, the reaction temperature is 355℃, and the volumetric space velocity of the fresh raw material oil is 3.0h. -1 . The amount of hydrogen mixed in the fixed control oil is 0.15wt% (hydrogen mixed amount / feed amount, that is, the amount of hydrogen mixed...

Embodiment 3

[0045] press figure 1 As shown in the process, a liquid phase circulating hydrogenation reactor and a gas-liquid countercurrent hydrogenation reactor are used in series. The liquid-phase hydrogenation reactor is provided with two hydrogenation catalyst beds, and the catalyst volume ratio of the two catalyst beds is 1:1; the gas-liquid countercurrent hydrogenation reactor is provided with a hydrogenation catalyst bed. Vacuum gas oil (VGO, sulfur content of 1.98wt%, nitrogen content of 2100μg / g) is hydrotreated at 380°C. The catalyst is the FF-24 catalyst developed and produced by Fushun Petrochemical Research Institute. First, the amount of dissolved hydrogen in the reaction system (0.17 wt%) is tested and measured, and then the process of the method of the invention is carried out. The pressure of the liquid phase hydrogenation reaction is 8.0MPa, the reaction temperature is 380℃, and the volumetric space velocity of the fresh raw oil is 2.5h. -1 . The amount of hydrogen mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com