Hydrogenation technology for diesel

A process method and diesel technology, applied in the field of dearomatization and hydrodesulfurization, can solve the problems of insufficient reaction rate of diesel desulfurization and large temperature rise, and achieve the effects of improving service life, uniform temperature distribution and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

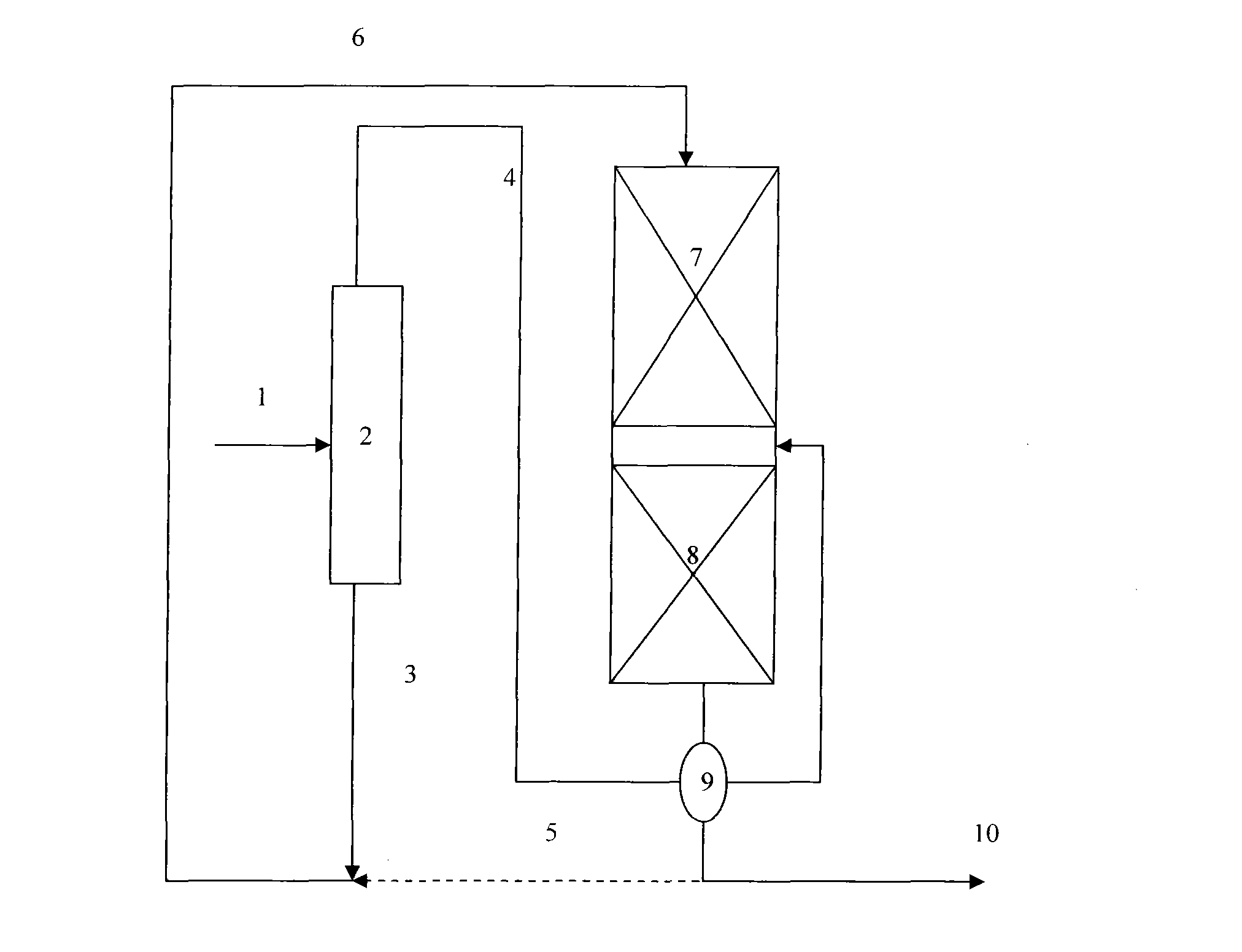

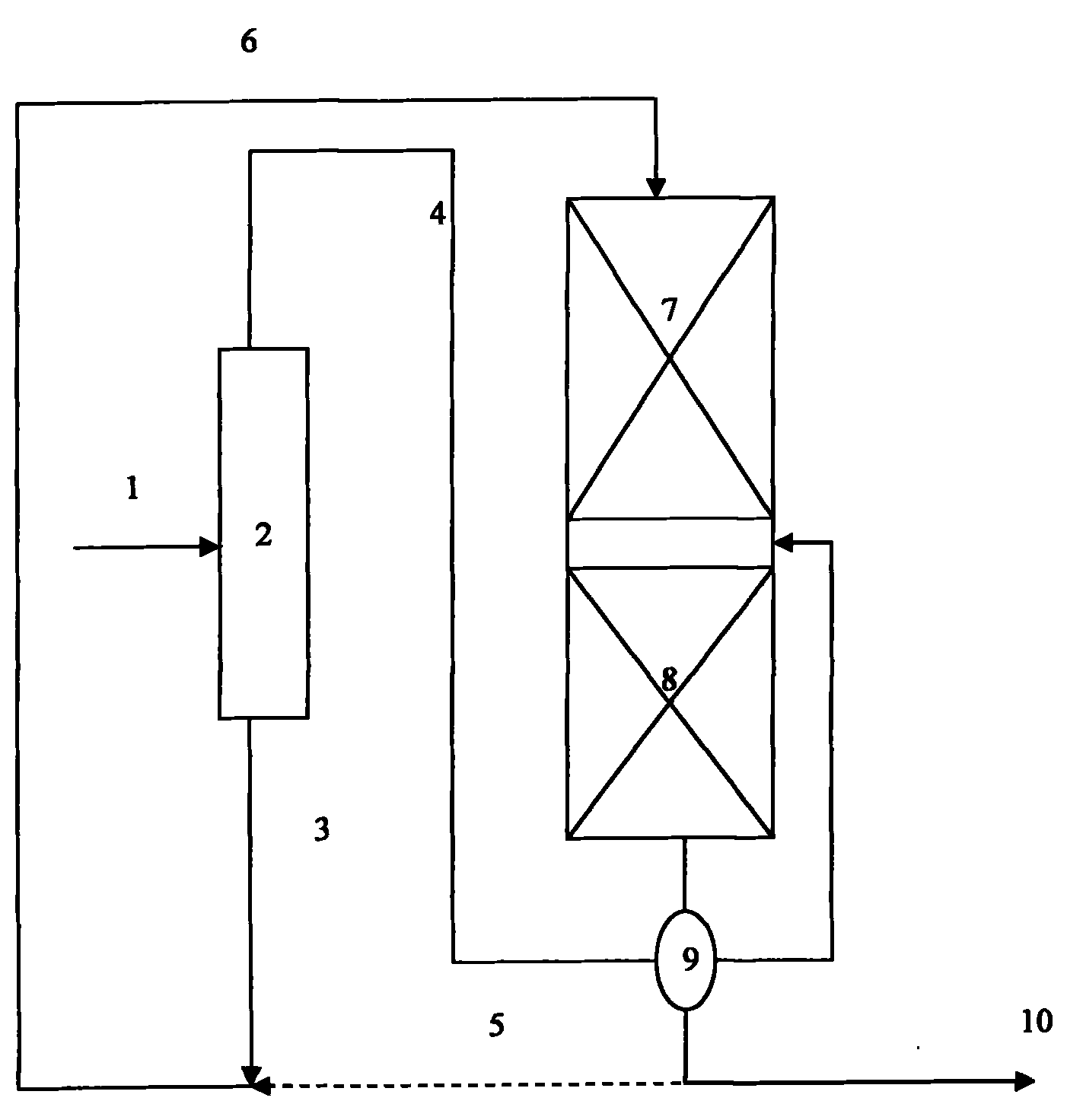

Method used

Image

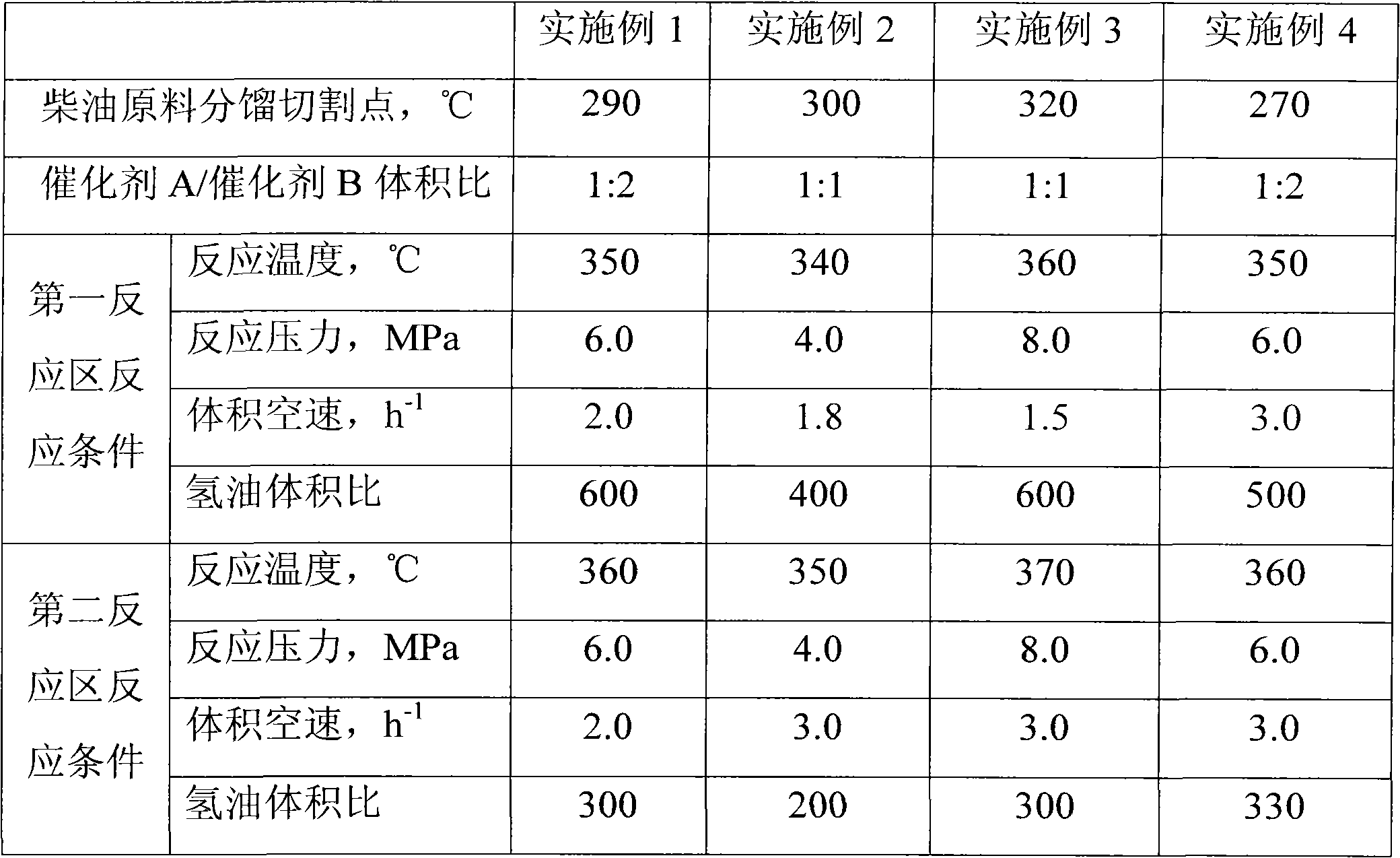

Examples

Embodiment Construction

[0019] In the diesel oil hydrogenation process of the present invention, the first reaction zone and the second reaction zone use a hydrofinishing catalyst, and the hydrofinishing catalyst refers to a non-precious metal hydrogenation catalyst with functions of hydrodesulfurization, hydrodenitrogenation, and aromatic hydrocarbon saturation. features can focus on certain aspects. The non-precious metal catalyst generally exists in an oxidized state before use, and requires conventional presulfidation treatment to convert the non-precious metal oxide into a sulfide to be reactive. Therefore, the non-precious metal catalyst should remain in a sulfide state during use. The hydrogenation catalyst used in the present invention can be a conventional diesel oil hydrotreating catalyst, generally with VIB group and / or Group VIII metal as the active component, with alumina or silicon-containing alumina as the carrier, and the VIB group metal is generally Mo and / or W, the Group VIII metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com