Hydro-processing method for producing ultra-low sulfur diesel

A kind of ultra-low sulfur diesel oil, hydrotreating technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

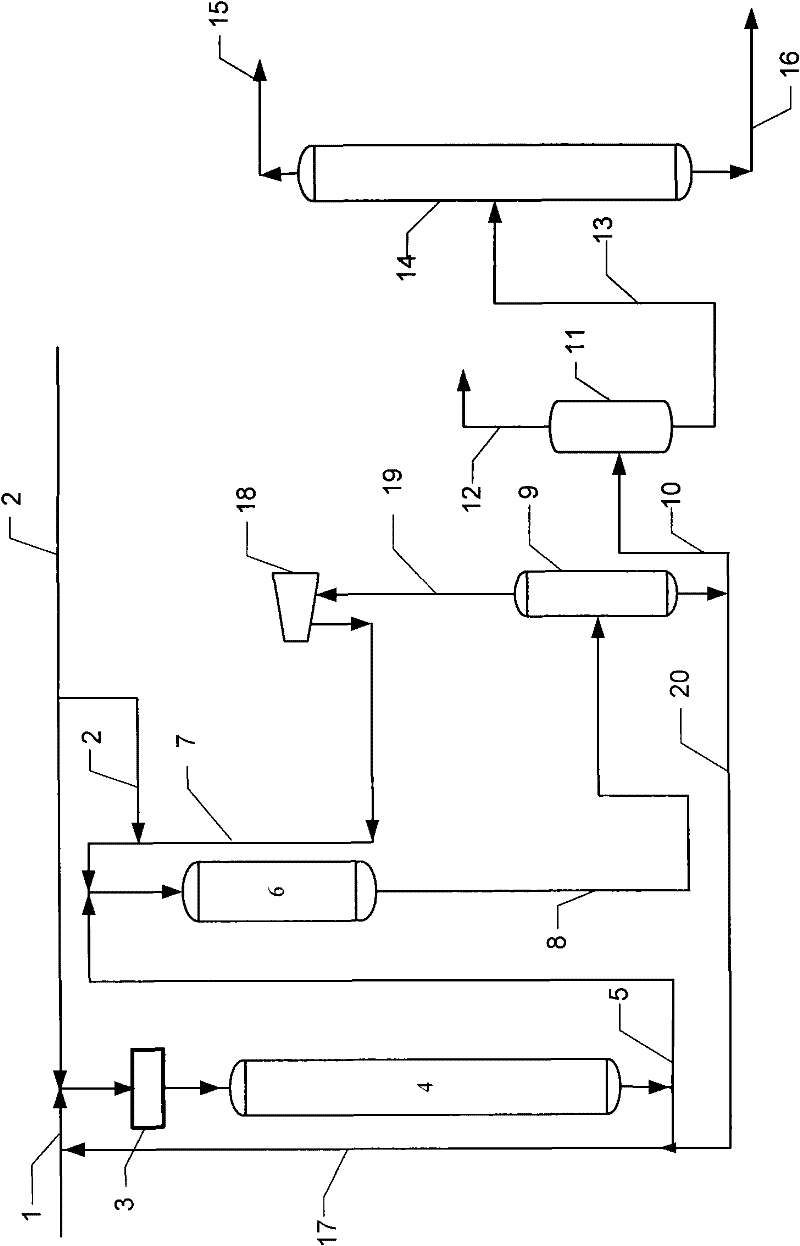

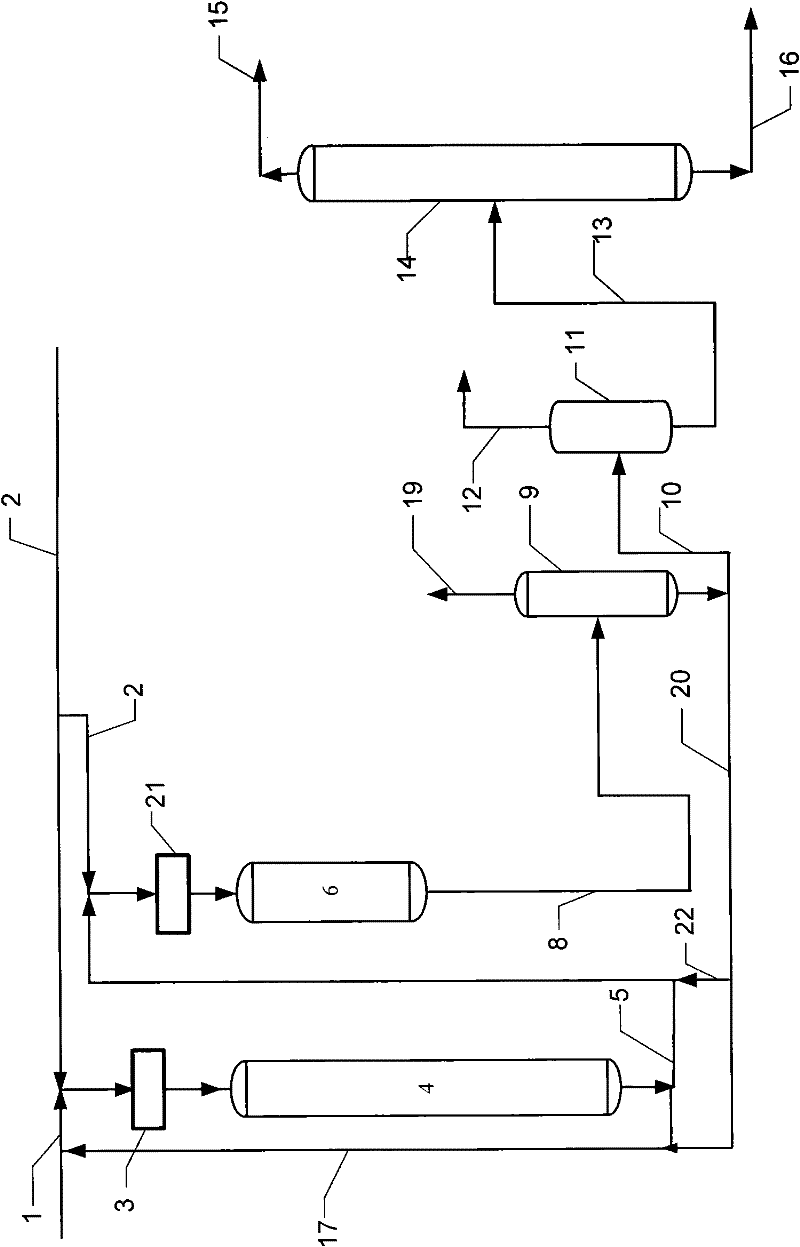

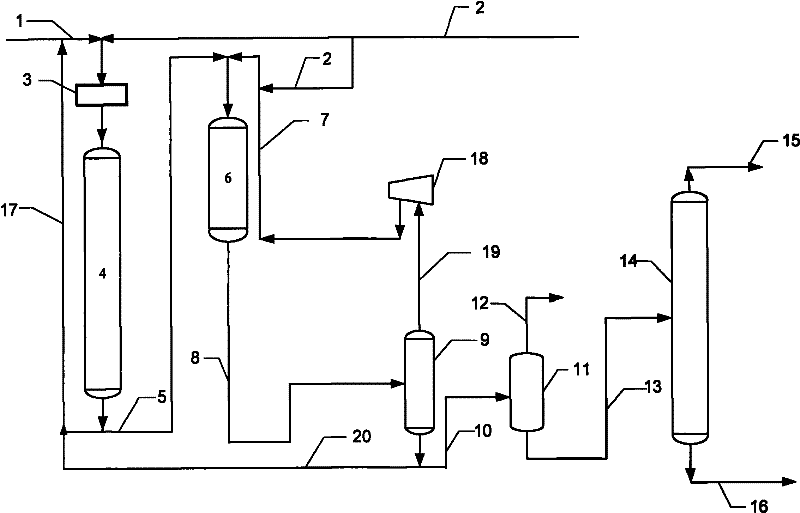

Image

Examples

Embodiment 1

[0035] The raw material oil A is fully mixed with new hydrogen, enters the static mixer, and then the liquid phase enters the first hydrotreatment reaction zone, and undergoes deep hydrodesulfurization reaction at high temperature and high space velocity; the reaction product is divided into two parts, and one part is recycled to At the inlet of the static mixer, the other part is mixed with circulating hydrogen and then enters the second hydrotreating reaction zone, where ultra-deep desulfurization, decolorization and aromatic hydrocarbon saturation reactions are carried out at low temperature and high space velocity, and the reaction products are cooled and separated. The hydrogen gas is circulating hydrogen, and the obtained liquid phase fraction enters the fractionation system to separate refined naphtha fraction and high-quality diesel fraction. Wherein the catalysts in the first reaction zone and the second reaction zone are catalyst A, the reaction conditions of this emb...

Embodiment 2

[0038] After the raw material oil B is fully mixed with the new hydrogen, it enters the static mixer, and then the pure liquid phase enters the first hydrotreatment reaction zone, and the deep hydrodesulfurization reaction is carried out at high temperature and high space velocity; the reaction product is fully mixed with the new hydrogen , into the static mixer, and then the pure liquid phase enters the second hydrotreating reaction zone, where ultra-deep desulfurization, decolorization and aromatics saturation reactions are carried out at low temperature and high space velocity, and the reaction products are cooled and separated. Enter the fractionation system to separate the refined naphtha fraction and high-quality diesel fraction; the remaining part is recycled to the inlet of the first hydrogenation reaction zone and the second hydrotreatment reaction zone. The first reaction zone is sequentially filled with catalyst A and catalyst B according to the flow direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com