Device and method for measuring fuel capacity of fuel tank for maritime robot

A technology of measuring device and robot, which is applied in the direction of measuring device, liquid level indicator and instrument for measuring physical variables, etc., can solve the problem of measuring the remaining oil in the fuel tank, etc., and achieve the effect of wide range of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

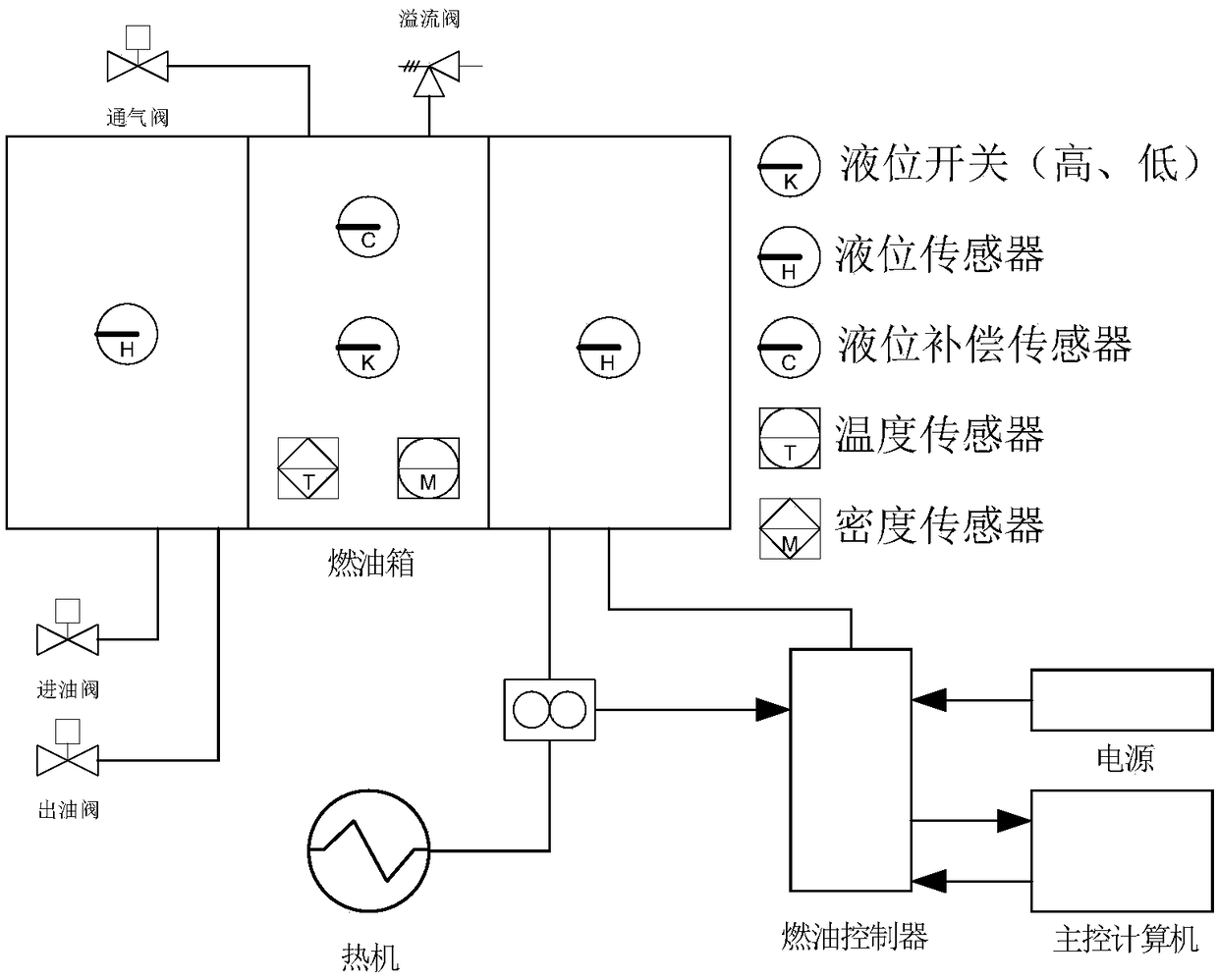

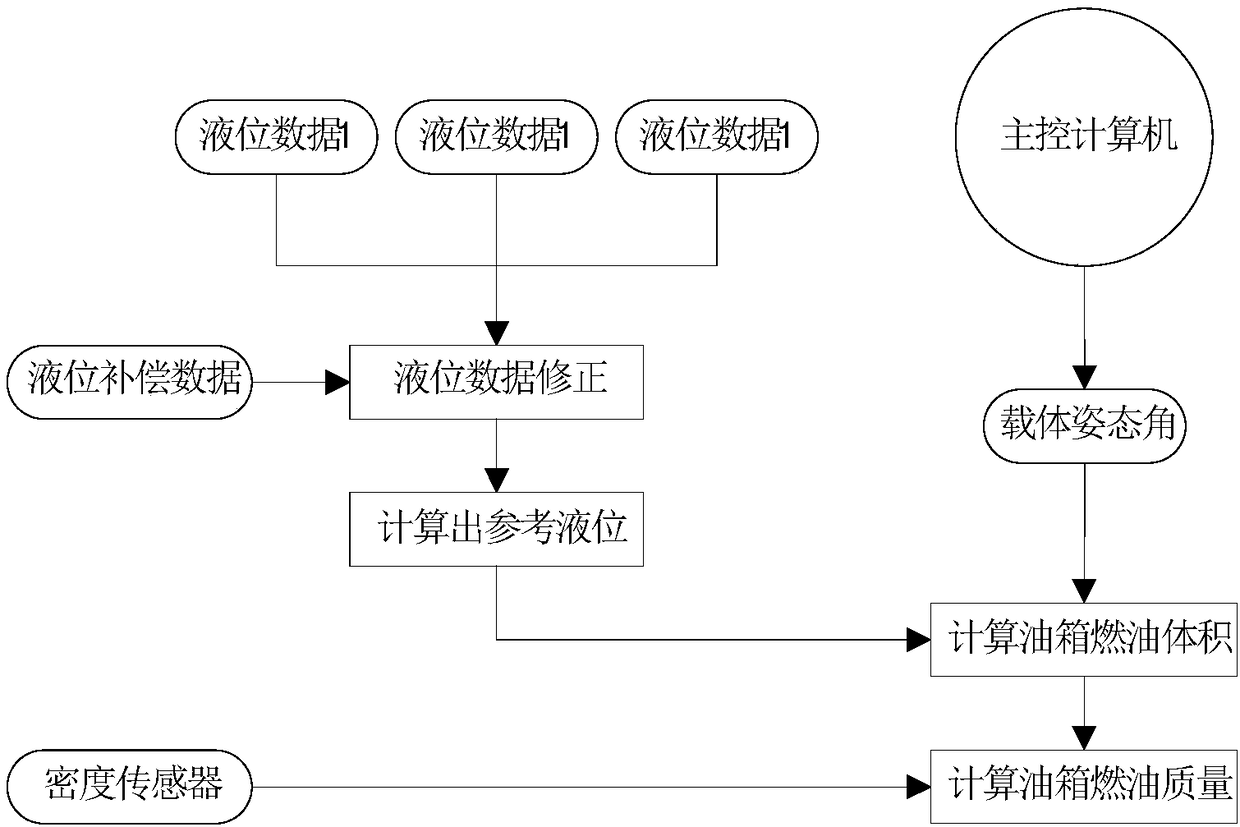

[0038] Such as figure 1 As shown, the device consists of a fuel tank, a fuel controller, sensors (including multiple liquid level sensors, compensation sensors, density sensors, flow sensors and temperature sensors), inlet and outlet ports and their switch valves, vents, and oil outlets. .

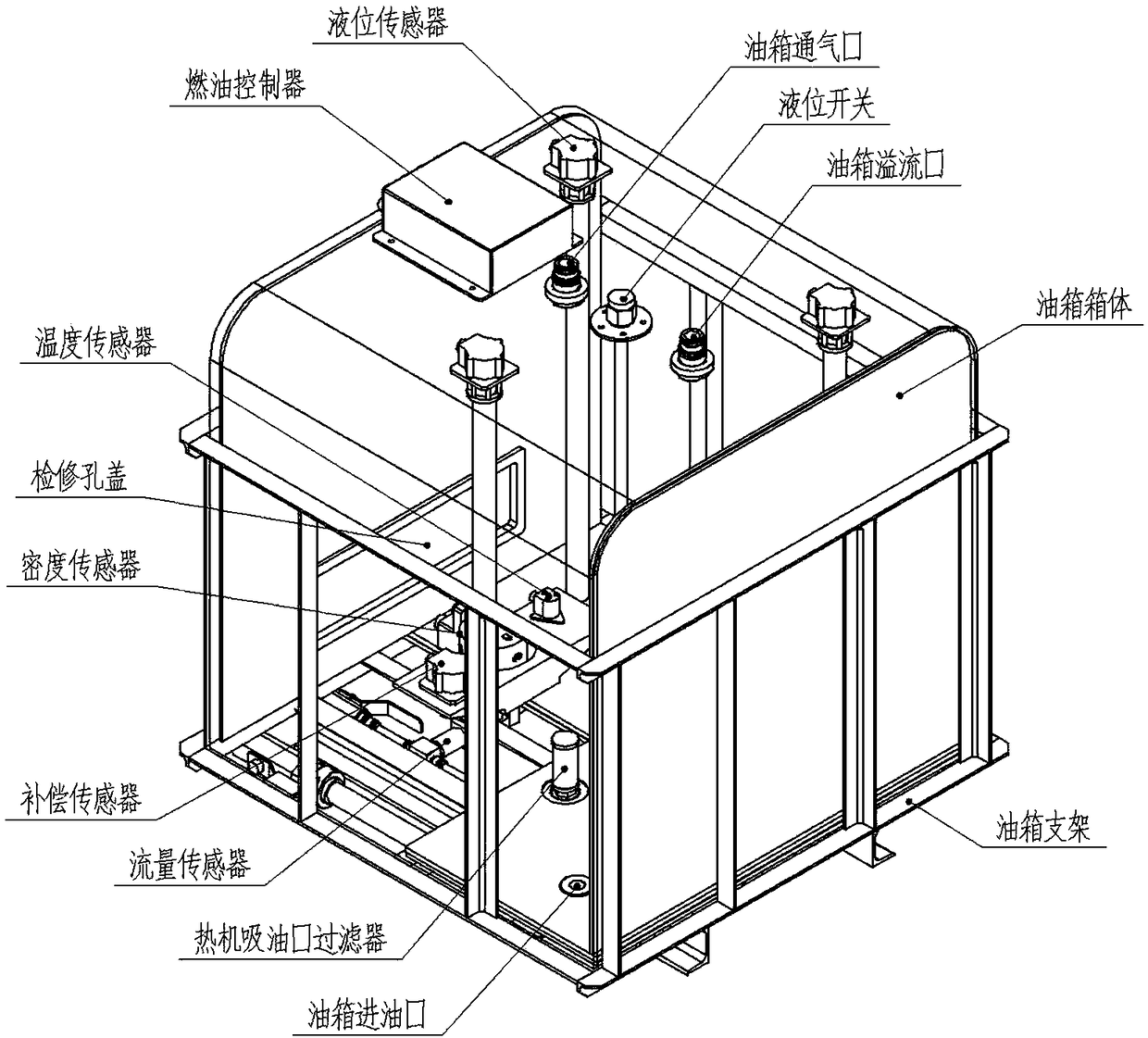

[0039] Such as figure 2 As shown, the liquid level sensor is an immersion liquid level sensor, which is installed at different positions on the top surface of the fuel tank to measure the position of the fuel level in the fuel tank. The compensation sensor, temperature sensor and density sensor are all installed inside the fuel tank and are responsible for measuring the properties of the fuel: the compensation sensor is used to compensate for changes in the dielectric constant of the fuel caused by environmental changes, fuel batches, etc.; the density ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com