Blast furnace ironmaking multi-objective intelligent optimization method based on adaptive genetic algorithm

A genetic algorithm and blast furnace ironmaking technology, applied in the field of multi-objective intelligent optimization of blast furnaces, can solve the problems of large fluctuations in product quality, low comprehensive energy efficiency, heavy environmental load, etc., to avoid local extremes, improve comprehensive energy efficiency, and efficiently and accurately take effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

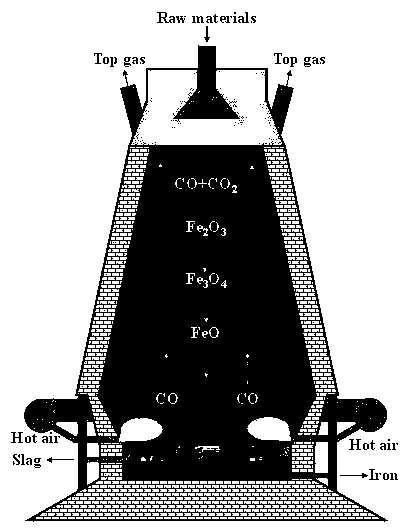

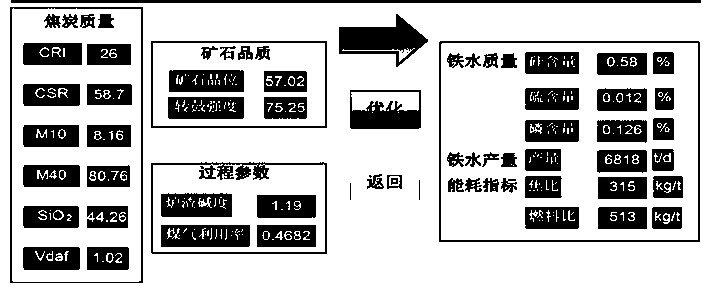

[0040] Take a domestic volume as 2650m 3 large blast furnace ( figure 1 ) as the object, a multi-objective intelligent optimization method for blast furnace ironmaking based on adaptive population genetic algorithm is described, the method has the following steps:

[0041] 1. For ironmaking data preprocessing, the data is standardized and normalized through data cleaning. Data preprocessing includes the data cleaning process, eliminating abnormal values, deleting invalid values, and aligning the time axis.

[0042] 2. Model the blast furnace ironmaking process, and use the deep learning method to establish a virtual model of the physical object. The blast furnace modeling method is:

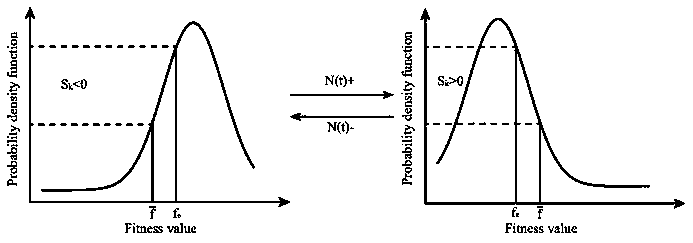

[0043] (2.1) Select the input and output variables of the blast furnace based on the correlation analysis and the furnace manager’s operating experience, and determine th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com