Full-automatic bottling liquor inspection machine

An inspection machine and fully automatic technology, applied in the direction of measuring devices, liquid/fluid solid measurement, instruments, etc., can solve the problems of false detection, increase of noise and energy consumption in the production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

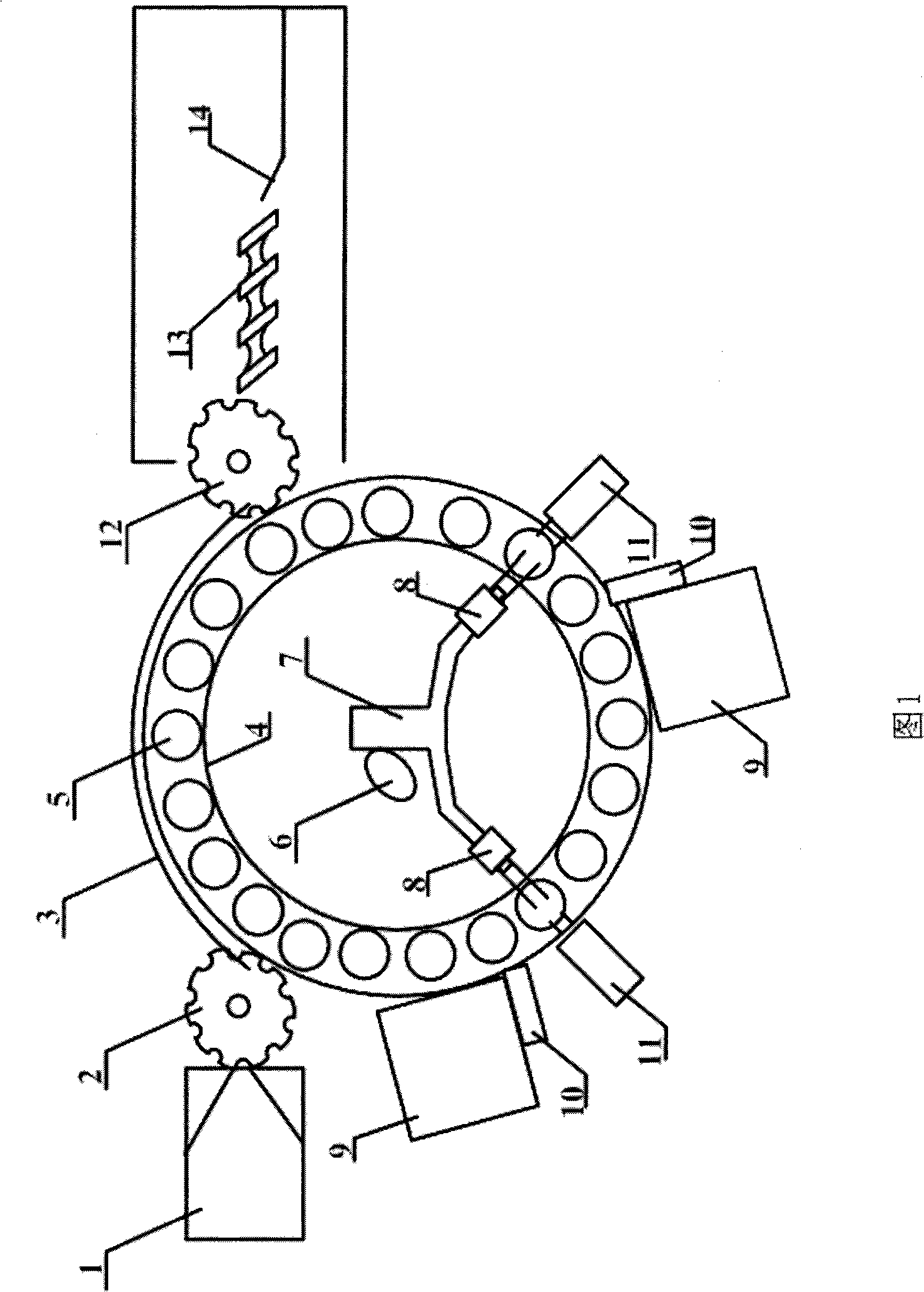

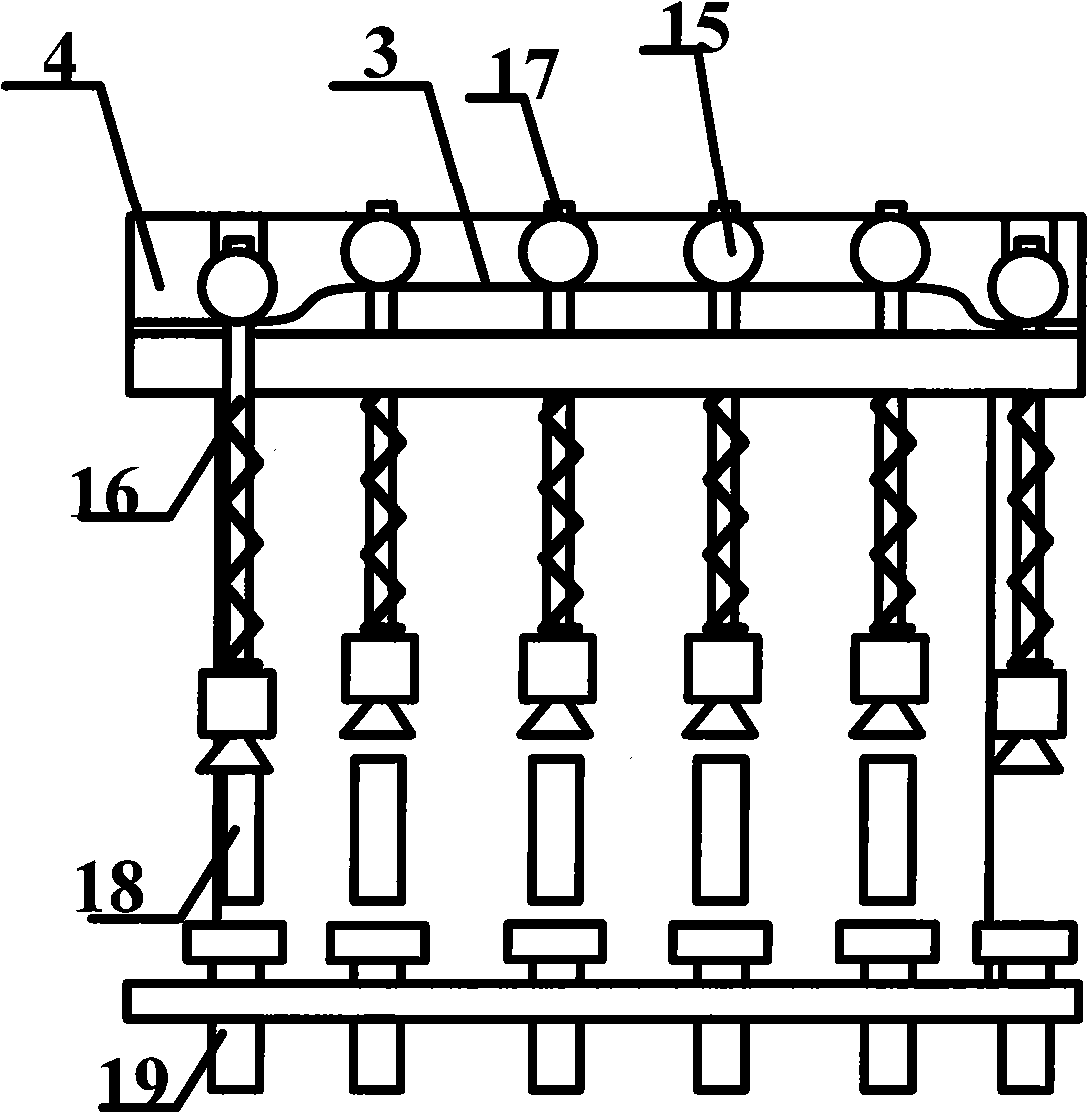

[0024] As shown in Figure 1, the bottle 25 to be inspected is sent to the conveyor belt 1 smoothly from the production line, and a tapered bottle unscrambling slope is set on the conveyor belt 1 near the bottle-infeed star wheel 2, so that the bottle-infeed star wheel 2 can only pass from the conveyor belt 1 each time. Take a pill bottle. Along with the bottle-feeding star wheel 2 rotates, the medicine bottle that gets will be sent to such as figure 2 On the clamp base 19 of the shown clamp 5 , as the detection stand 4 rotates, the unlocking bearing 15 of the clamp 5 slides down from the clamp unlocking mechanism 3 . Under the action of the recoil spring 16, the rotary flat head of the bottom of the down-pressing rod 17 presses the tested drug bottle 25, so that the tested drug bottle 25 is clamped vertically. Simultaneously, the bottle 25 to be inspected breaks away from the star wheel 2 for entering bottles.

[0025] The detection platform 4 rotates towards the centrifugal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com