First surface mirror with chromium nitride layer

a chromium nitride and mirror technology, applied in the direction of mirrors, mountings, instruments, etc., can solve the problems of poor reflection, glass/cr structure suffer from pinhole related problems, mirror structure is susceptible to pinhole formation in the metallic cr layer, etc., to improve the durability of the mirror

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

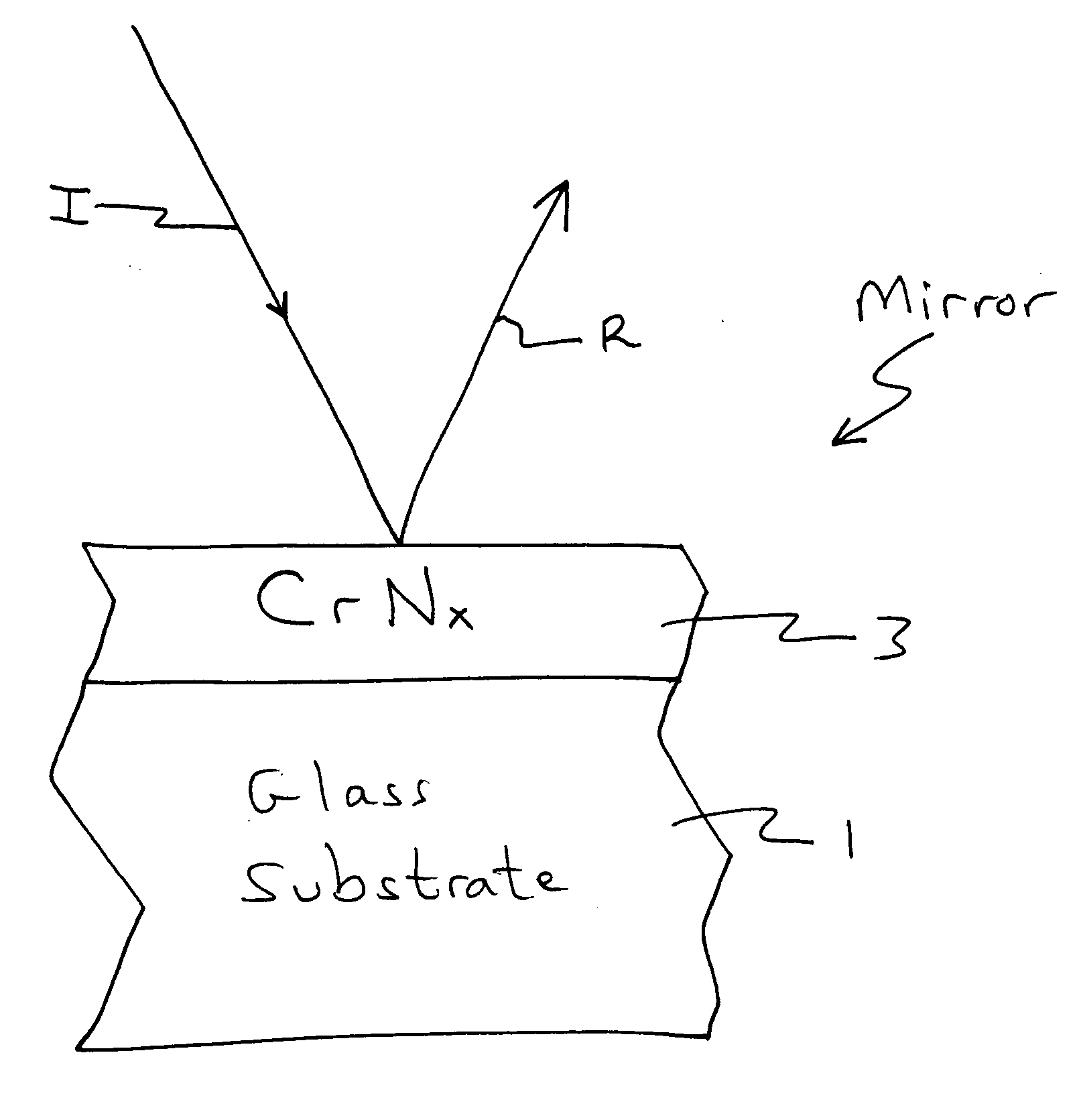

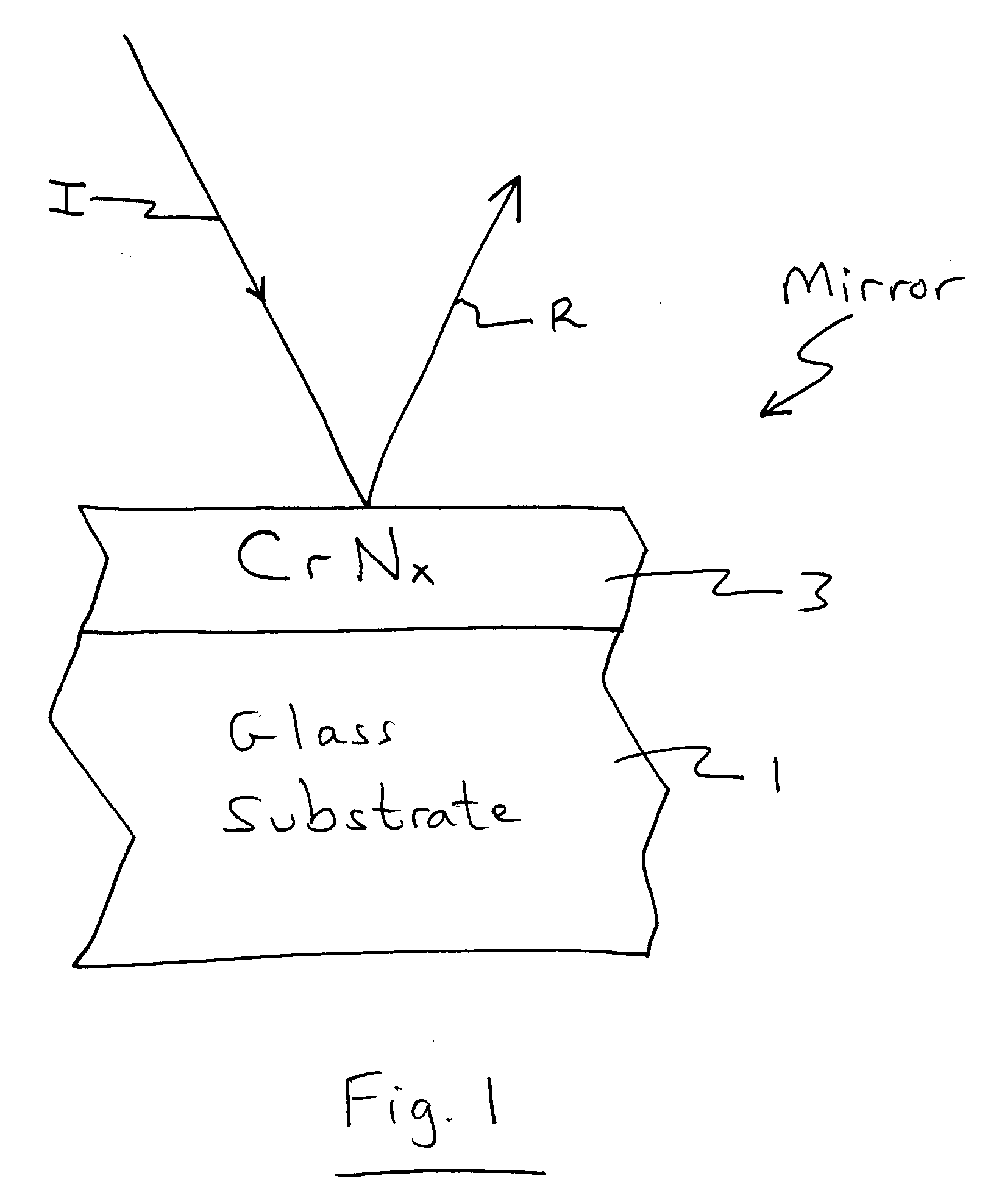

[0035] The following example first surface mirrors were made and tested, but are not intended to be limiting. Example 1 had a layer stack of glass / Cr, whereas the other examples all had a layer stack of glass / CrNx as shown in FIG. 1. The glass substrate 1 was about 2.3 mm thick. The examples were made by sputtering the Cr inclusive layer on the substrate using a Cr sputtering target in a gas atmosphere, using the following process parameters. Lower linespeeds were used for thicker layers and thus less visible transmission if desired.

Ex. 1Ex. 2Ex. 3Ex. 4Ex. 5Ex. 6Ex. 7N2 gas flow (sccm):09213113116019894Ar gas flow (sccm):970878825825790747878Total gas (sccm):970970956956950945972% N gas flow:09%14%14%17%21%10%Linespeed (ipm):1601601421501428590pressure (mTorr):2.62.52.42.42.32.22.5

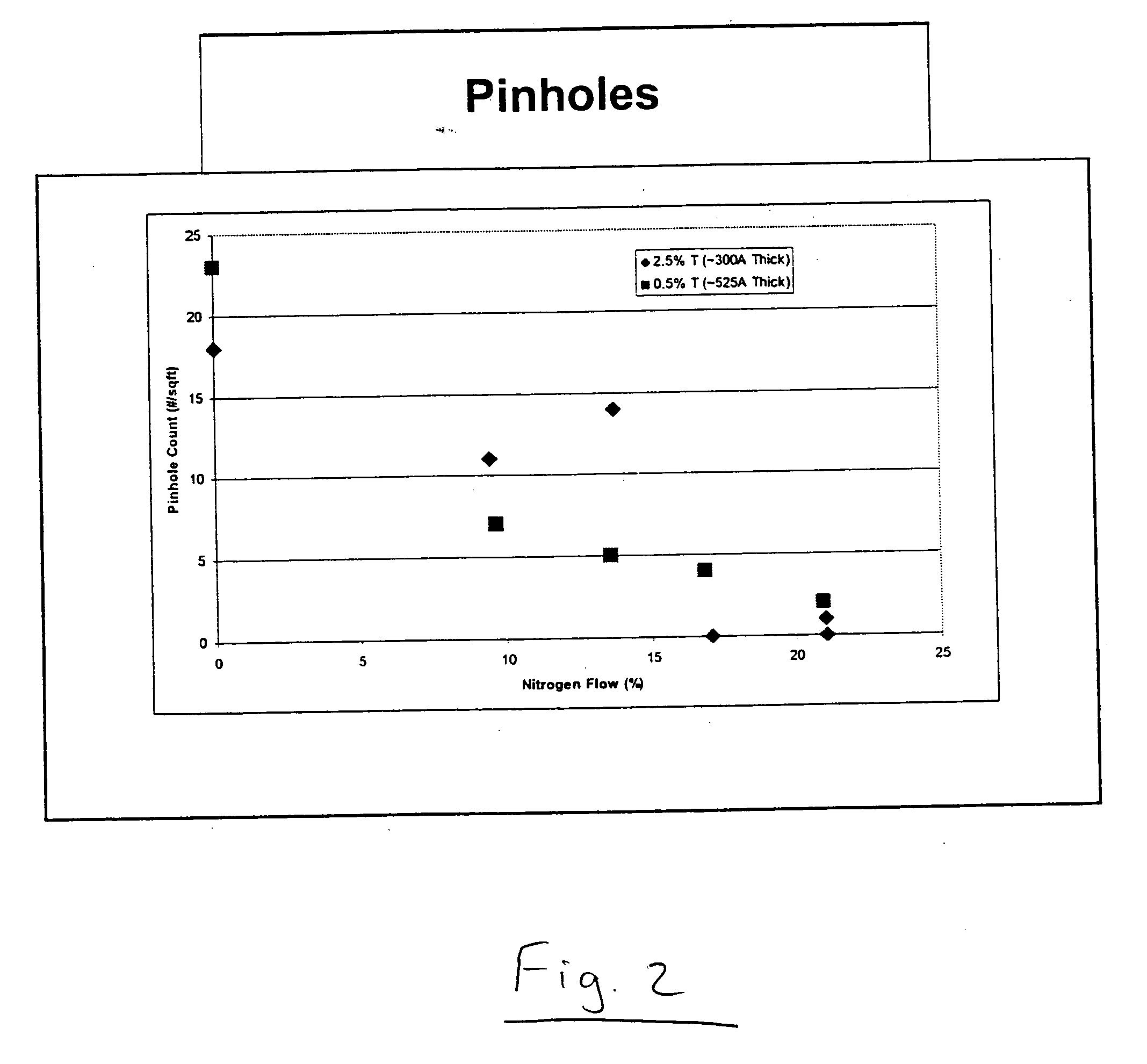

[0036] It was found that the mirrors of Examples 2-6 (which included nitrogen in the Cr inclusive layer 3) had much fewer pinholes than did the mirror of Example 1 (which had a metallic Cr layer 3—thus, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com