Chemical powder components of 2507 type super double-phase stainless steel flux-cored wire

A technology of duplex stainless steel and flux-cored welding wire, which is applied in welding media, welding equipment, welding/cutting media/materials, etc. It can solve problems such as difficulty in adapting to the degree of automation, inability to realize automatic welding, and low cost performance of welding wire. Good process performance, excellent welding process performance, no welding spatter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in conjunction with the given embodiment:

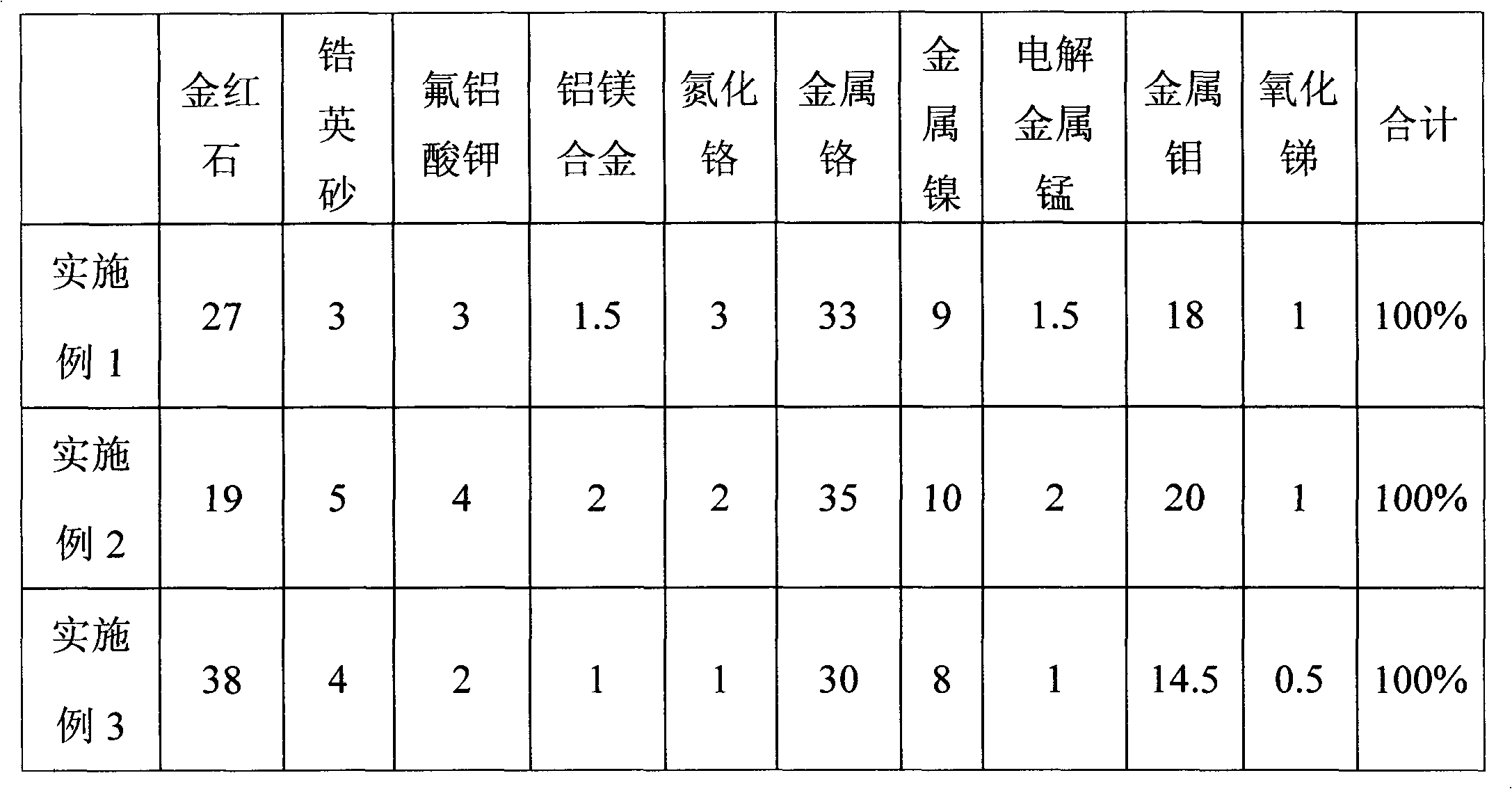

[0018] Table 1 Powder composition (%)

[0019]

[0020] An example of implementation effect: See Table 2 and Table 3 for the chemical composition of the deposited metal and the mechanical properties (%) of the deposited metal of the 2507 type super duplex stainless steel flux-cored wire prepared by the powder of the present invention.

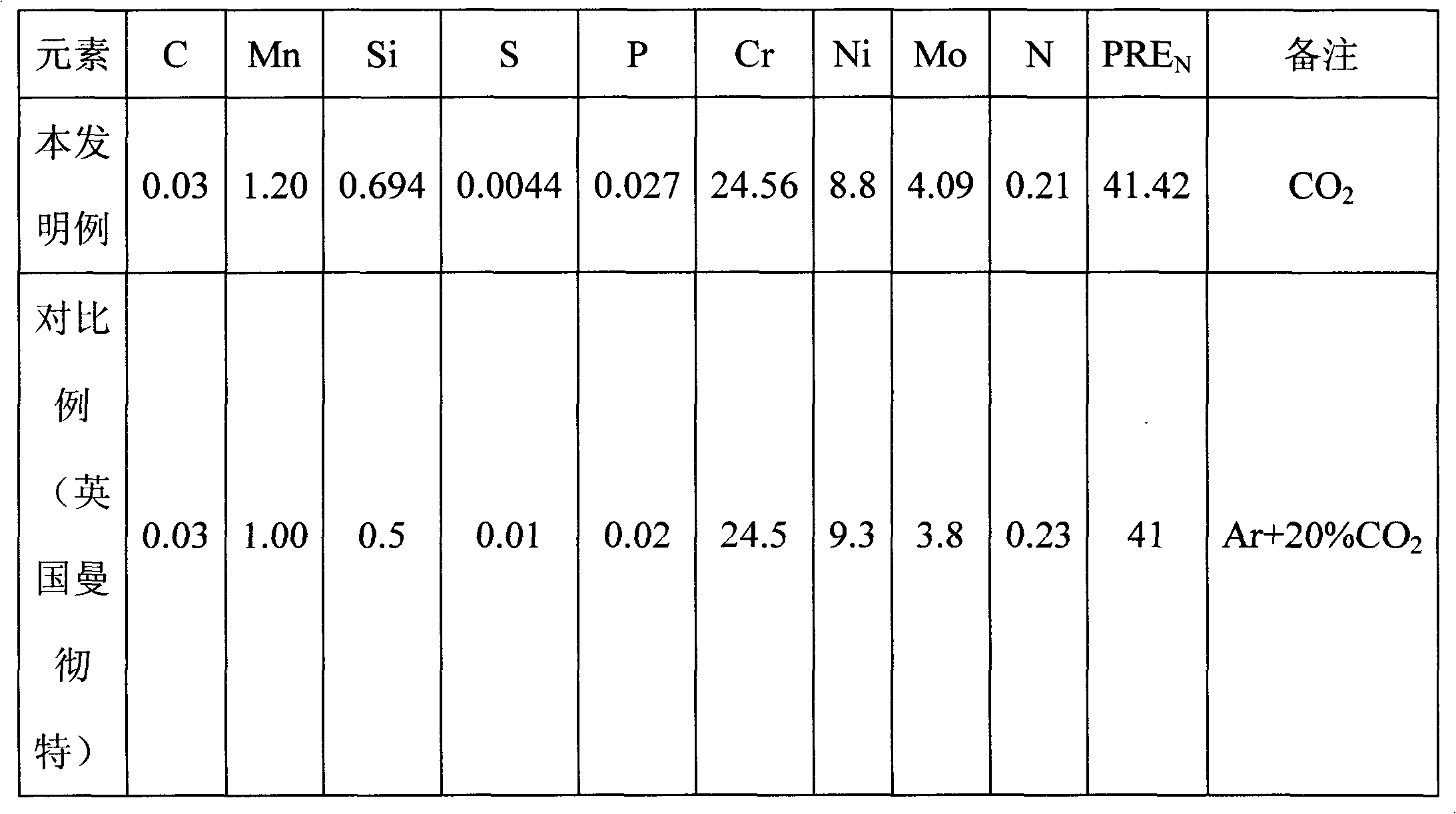

[0021] Table 22507 Super Duplex Stainless Steel Flux-Cored Wire Deposited Metal Chemical Composition (%)

[0022]

[0023] Note: PRE N is the pitting resistance coefficient. PRE N =Cr+3.3Mo+16N

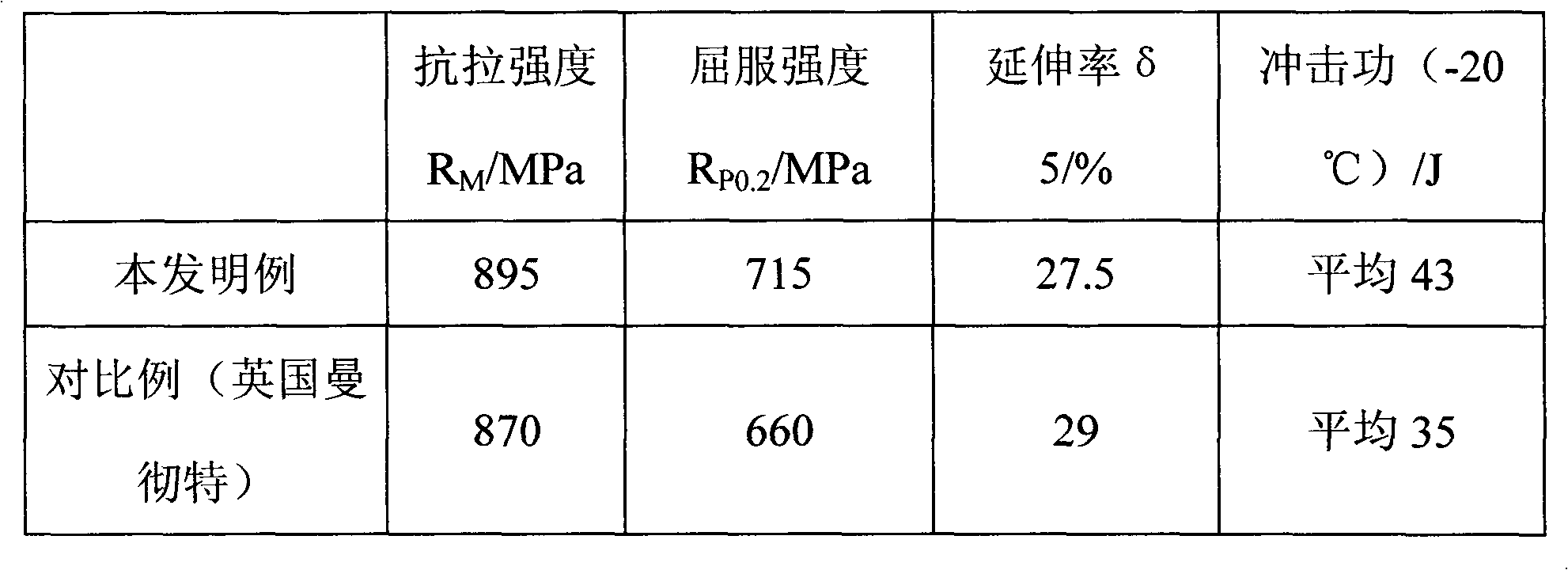

[0024] Table 3 Deposited metal properties of 2507 type super duplex stainless steel flux cored wire

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com