High-efficiency ultrasonic impact head for soldering joint stress release

A welding seam stress and ultrasonic impact technology, applied in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, unsatisfactory processing effect, and low processing efficiency of long welding seams, and achieve good economic benefits. Good impact effect, improved impact efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

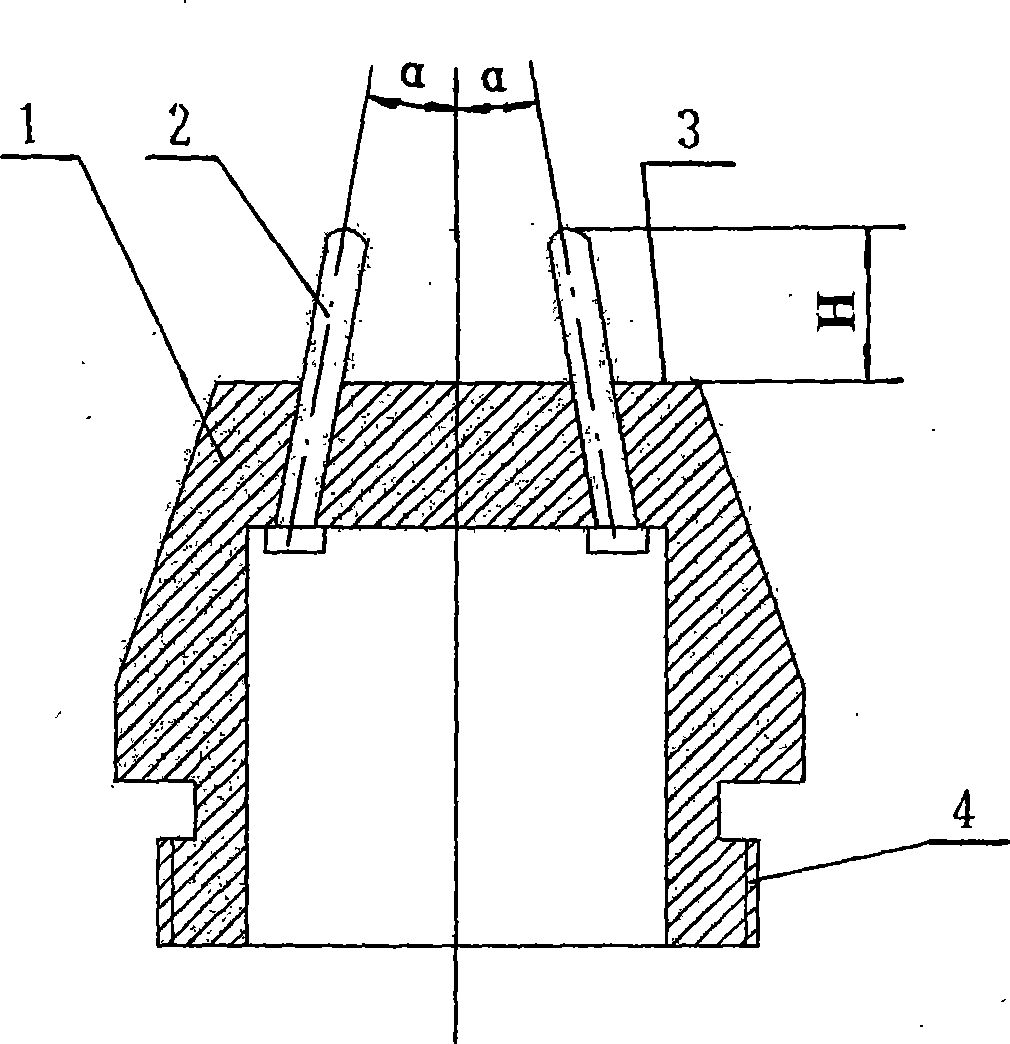

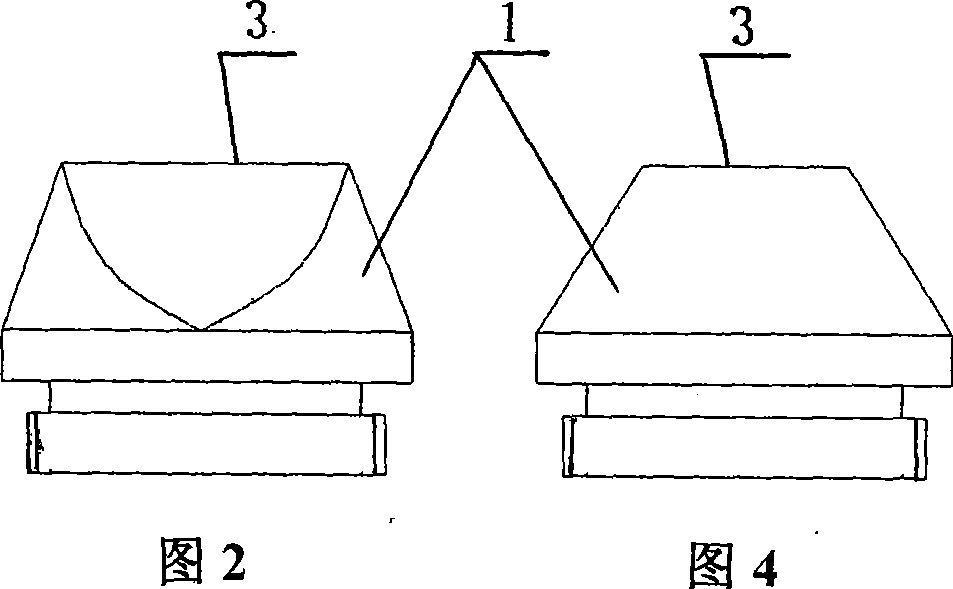

[0015] Such as figure 1 As shown in Figure 4, a high-efficiency impact head for weld stress relief, which includes an impact head body 1 fitted with an ultrasonic impact gun and threaded, the joint surface of the impact head body and the ultrasonic impact gun can be used The gasket maintains its resonance fit, and the thickness of the gasket is 3 to 5mm.

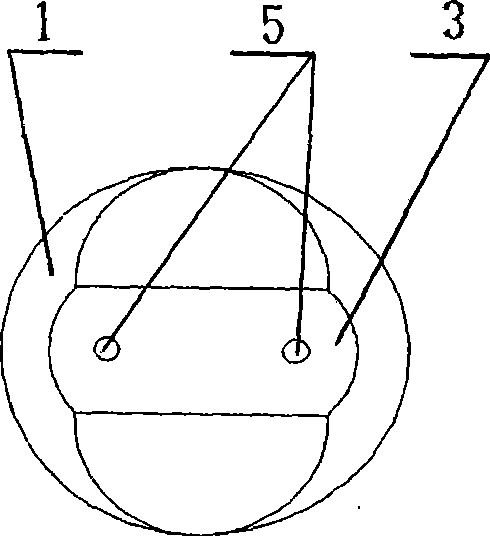

[0016] The upper part of the impact head main body 1 is a special-shaped cylinder, its two opposite faces are chamfered, and the other two opposite faces are inverted into an arc shape, forming a nearly rectangular top plane 3 composed of two parallel faces and two arc faces on the periphery. Two circular through holes are processed on the top plane 3, that is, impact pinholes 5. The two impact pinholes are symmetrically distributed on both sides of the central axis, and are inclined inwardly to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com