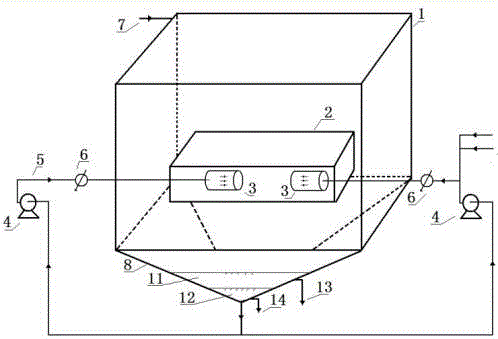

A kind of impinging flow reactor and its application

A technology of impingement flow reactor and reactor, which is used in chemical/physical/physical-chemical stationary reactors, petroleum industry, refined hydrocarbon oil, etc. It can solve the problems of temperature rise and difficult pressure control, and achieve long-term stable operation. , Improve the impact efficiency, the effect of high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0022] Embodiment 1~5 (continuous operation)

[0023] The product is continuously extracted from the oil phase extraction port, cooled to room temperature, and then washed with water, alkali washed, washed with water, and adsorbed and desulfurized in order to remove the polar sulfides generated by oxidation (mainly thiophene compounds in diesel oil are Oxidation to generate corresponding sulfone compounds), sampling and analysis, the sulfur content in the oil sample was quantitatively analyzed by coulometric method. The reaction conditions and results are shown in Table 1. There is no vibration in the reactor during the whole reaction process, and the reaction pressure and temperature can be controlled smoothly.

[0024] Table 1

[0025] serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com