Ultrasonic multi-head impact device and method for manufacturing materials such as robots

An ultrasonic impact and robot technology, which is used in devices for controlling the refinement of the surface layer and internal structure of components after additive, and in the field of hot working hammer forging technology, can solve problems such as difficult to achieve engineering applications, prevent slippage or fall off, and prevent installation. Simple and effective for eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

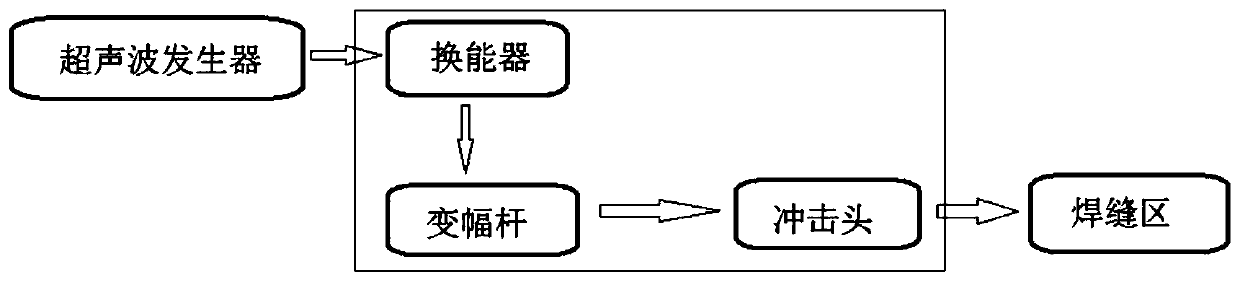

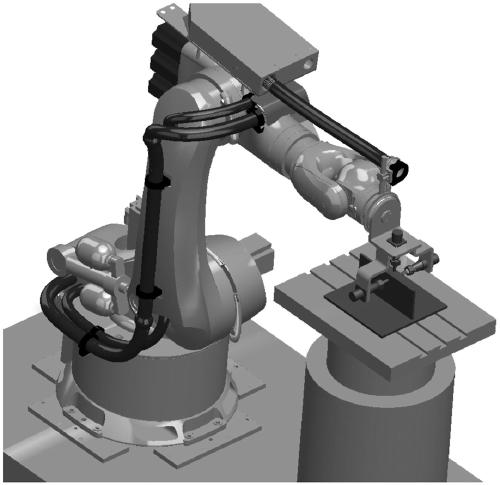

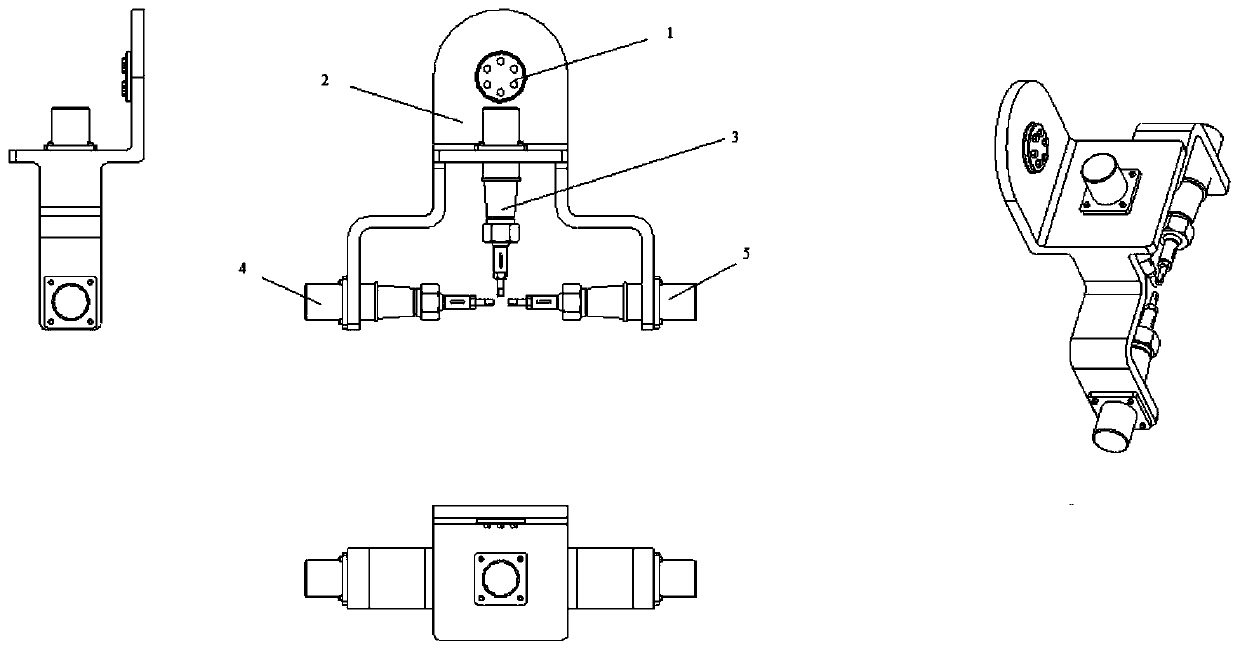

[0033]The equipment used in this embodiment includes: a multi-degree-of-freedom articulated industrial robot and a corresponding power control system, an ultrasonic multi-head impact device, an ultrasonic generator and corresponding equipment. The industrial robot is fixed, and the workpiece substrate to be processed is fixed on the working table of the robot positioner, and the forming and manufacturing of thin-walled wall components is completed through arc wire additive manufacturing. The device of the invention is connected with the end of the robot, and the robot is controlled by programming to complete the transformation operation of the space posture and the track. Ultrasonic impact metal materials are mainly light alloys, such as titanium alloy TC4 materials or aluminum alloy materials.

[0034] The ultrasonic impact equipment used in this embodiment, the ultrasonic impact gun can work continuously for more than 8 hours under the working condition of 80% full load. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com