Photoelectric material and device impulse voltage testing device and method

A photoelectric material and impulse voltage technology, applied in the direction of measuring devices, testing dielectric strength, instruments, etc., can solve the problems of narrow carrier waveform range, large floor area, and inaccurate measurement and adjustment of voltage waveform, so as to reduce operation The effect of difficulty, low cost, fast and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

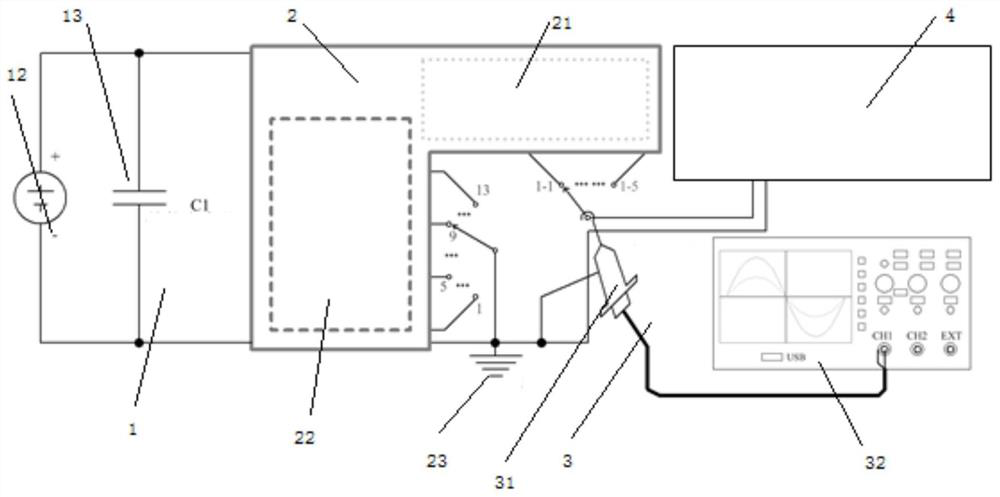

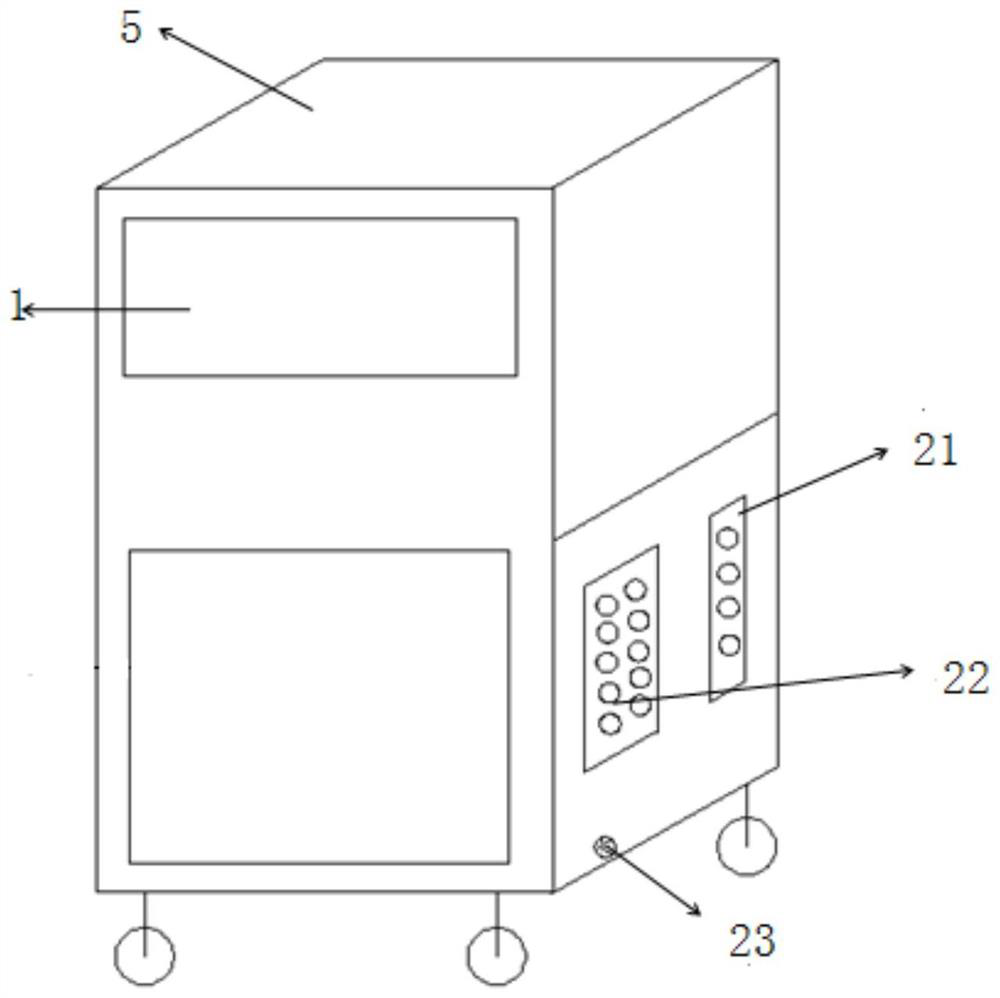

[0029] see figure 1 Or 2, the present invention provides a kind of technical scheme:

[0030] A photoelectric material and device impulse voltage testing device, comprising a charging assembly 1, an adjustment output assembly 2, a monitoring assembly 3 and a carrier to be tested 4; the charging assembly 1 is connected to the adjustment output assembly 2, and the adjustment output assembly 2 is connected to the The test carrier 4 is connected, the connection between the monitoring component 3 and the test carrier 4 , and the test component is used to monitor the voltage at both ends of the test carrier 4 .

[0031] The charging assembly 1 is used for connecting with an external power source and charging, and the charging assembly 1 includes a control panel 11, a controller, a charging power supply 12 and an energy storage capacitor 13; the charging power supply 12 is connected to the energy storage capacitor 13 , the control panel is connected to the controller, the controller...

Embodiment 2

[0043] This embodiment provides a method for testing the impulse voltage of optoelectronic materials and devices; the specific steps are as follows:

[0044] Step 1: Pressure test, according to the national standard peak voltage of different optoelectronic materials and devices, repeatedly set the capacitor reference setting voltage, and then output until the peak voltage displayed on the oscilloscope meets the national standard peak voltage;

[0045] Step 2: Wave modulation. Since the optoelectronic material and device must be impacted according to the voltage determined by the specific voltage waveform during the test to know whether the optoelectronic material and device are compliant, the output voltage waveform needs to be modulated;

[0046] First, observe the shape of the preliminary waveform in step 1, compare it with the standard waveform, control the rise time of the output waveform through the leading edge matching network 21, and reduce the resistance value in the l...

Embodiment 3

[0052] The load to be tested in this solution is a type of photovoltaic module made of 72 crystalline silicon materials. When setting the reference voltage, it needs to be gradually adjusted from low voltage to high voltage. When the voltage reaches the rated test voltage of the optoelectronic material and device, the adjustment of the voltage setting knob can be stopped, and the test of the optoelectronic material and device can be started.

[0053] When the voltage is set, turn the voltage setting knob, and the digital display voltage of the benchmark setting will change accordingly, thereby changing the output voltage of the charging power supply 12 (at this time, the charging power supply 12 has no high-voltage output, and it can only be activated after clicking the single or continuous button. output by high voltage).

[0054] When the optoelectronic material and device type are 72 crystalline silicon material photovoltaic modules and connected, and the test method is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com