Reciprocating impact oblique tooth discharging shovel of reciprocating impact mining machine

A technology of excavator and helical teeth, which is applied in the field of reciprocating impact helical tooth discharge shovel of reciprocating impact excavators, can solve the problems of difficult discharge and blanking, inability to reciprocate impact, high failure rate, etc., and achieve the goal of reducing shaking and improving impact efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

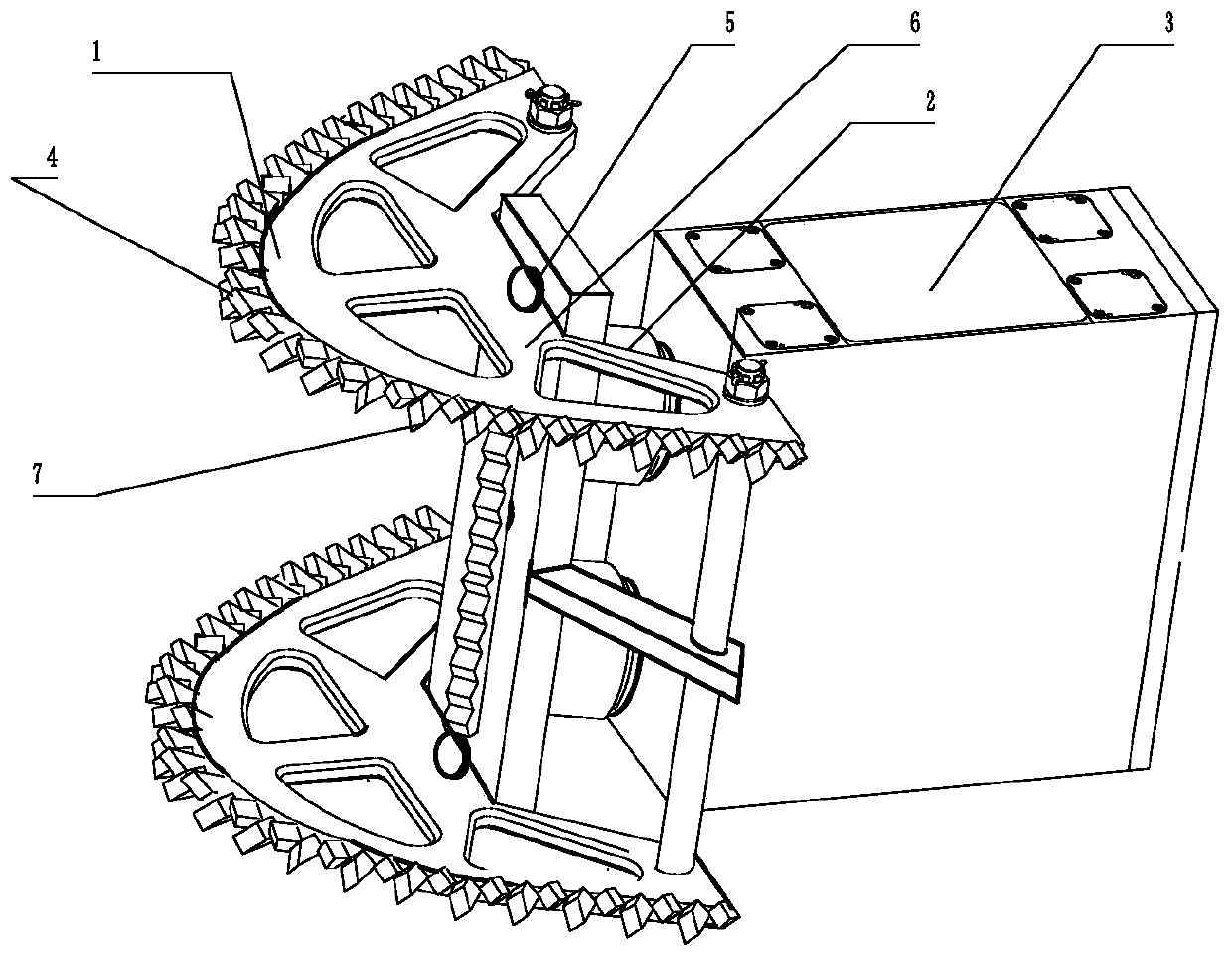

[0071] Such as figure 1 As shown, a reciprocating impact excavator reciprocating impact helical tooth discharge shovel includes a reciprocating impact box and a reciprocating impact helical tooth discharge shovel 1, and the reciprocating impact box includes a reciprocating impact box 3, a reciprocating impact power part and a reciprocating impact guide 2 etc., the reciprocating impact power part is arranged in the reciprocating impact box 3, and the reciprocating impact power part is supported by the reciprocating impact box 3 to drive the reciprocating impact guide 2, and one end of the reciprocating impact guide 2 extends out of the reciprocating impact box 3, and the reciprocating impact The helical tooth discharge shovel 1 includes the main tooth seat 5, the main punch tooth 4, the side discharge tooth wing plate 6 and the side discharge helical tooth 7, etc., and the main tooth seat 5 is arranged on the reciprocating impact mechanism extending outside the reciprocating imp...

Embodiment 2

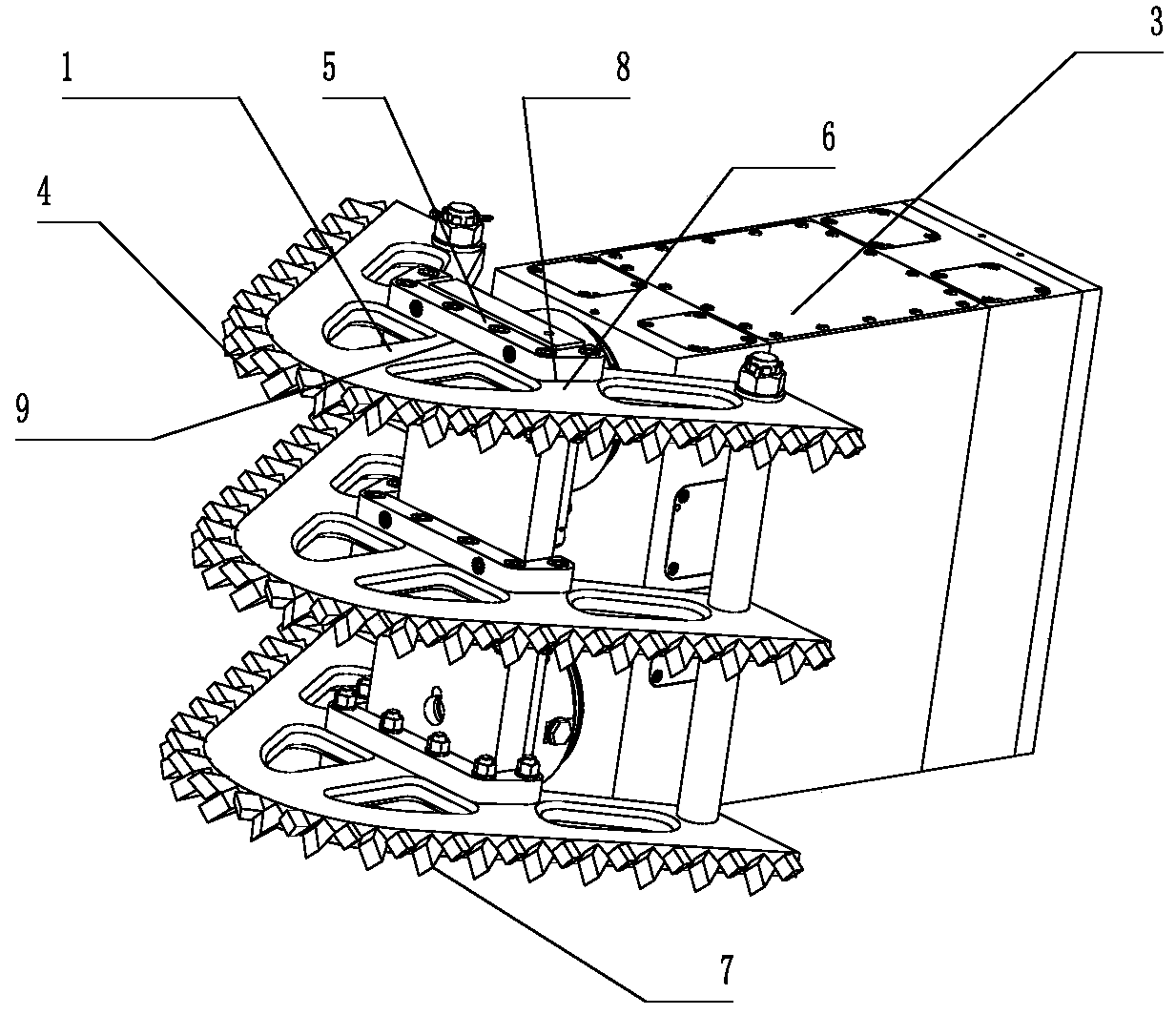

[0077] Such as figure 2 As shown, a reciprocating impact excavator reciprocating impact helical tooth discharge shovel, when the main gear seat 5 and the main punch tooth 4 are connected separately, the upper part of the side discharge tooth wing plate 6 protrudes from the top of the main tooth seat 5 and there is a side wing plate The anti-rotation surface 8, the main punch tooth 4 is set on the main gear seat 5 to fasten the side wing plate anti-rotation surface 9 and the side wing plate anti-rotation surface 8 to prevent the main punch tooth 4 from rotating, the main punch tooth 4 and the main tooth seat 5 pass through the cone The surface buckles, and the anti-return part only prevents the main punching tooth 4 from falling off in the main tooth seat 5 because the anti-rotation surface 8 of the side wing plate is not subjected to rotation and shearing, and the anti-rotation surface 8 of the side wing plate has a righting effect on the main punching tooth 4.

[0078] The m...

Embodiment 3

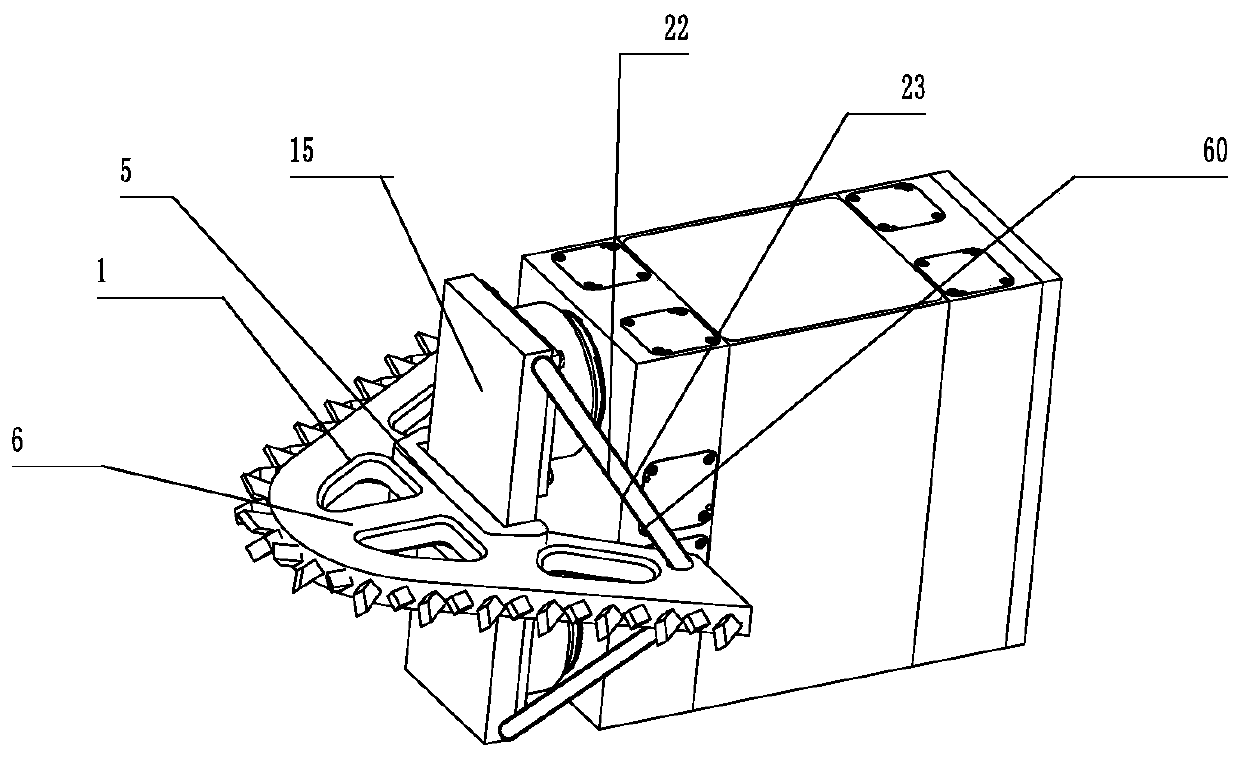

[0081] Such as image 3 As shown, the reciprocating impact helical tooth discharge shovel 1 also includes a reciprocating impact shovel plate 15. When a main tooth seat 5 is provided, a side discharge tooth wing plate rotation member 22 is set on the side discharge tooth wing plate 6. When When the rotary part 22 of the side discharge tooth flap is connected separately with the side discharge tooth flap 6, one end of the rotary part 22 of the side discharge tooth flap is connected with the side discharge tooth flap 6, and the other end is connected with the reciprocating impact shovel The plate 15 is connected, the side discharge tooth flap rotation part 22 is connected with the side discharge tooth flap through the rod perforation sleeve 23, the side discharge tooth flap rotation part 22 includes the rod perforation sleeve stop flap rotation part 60 , The side discharge tooth flap rotation member 22 prevents the side discharge tooth flap 6 from rotating, and prevents the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com