Screening device for petroleum-contaminated soil treatment

A soil treatment and oil pollution technology, which is applied in the field of soil pollution, can solve problems such as unfavorable oil-contaminated soil screening, affecting soil testing results, and clogging of screening devices, so as to improve the effect, enhance screening efficiency, and reduce the probability of clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

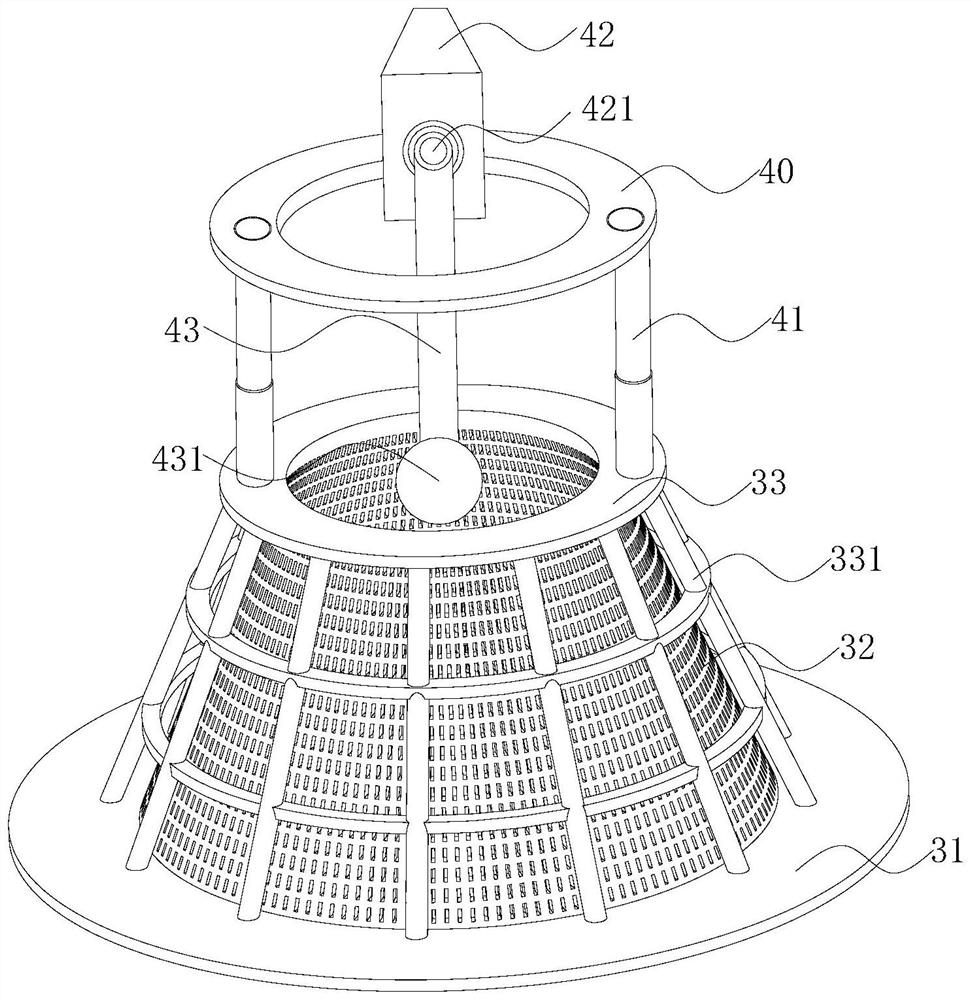

[0041] according to Figure 9-Figure 10 The upper end of the impact block 431 is fixedly connected with a threaded rod 4311, the lower end of the impact block 431 is fixedly connected with an internal threaded pipe 4312, and the outer surface of the threaded rod 4311 and the inner side wall of the internal threaded pipe 4312 are distributed with corresponding Adaptive threads, two adjacent impact blocks 431 are threaded through corresponding threaded rods 4311 and internally threaded tubes 4312 .

Embodiment 2

[0043] according to Figure 11 As shown, the upper end of the impact block 431 is fixedly connected with a clamping rod 4314, and the lower end of the impact block 431 is fixedly connected with a clamping tube 4313, and two adjacent impact blocks 431 pass through the corresponding clamping rod 4314 Interference fit with snap-on tube 4313.

[0044] It should be noted that, before screening, through the threaded connection between the threaded rod 4311 and the internally threaded pipe 4312, or through the interference fit between the clamping rod 4314 and the clamping tube 4313, the impact between the impact block 431 and the impact block 431 is realized. The installation is to install multiple impact blocks 431 together in a threaded connection or clamping mode, thereby increasing the impact area of the impact block 431 during the impact process, and improving the single impact efficiency of the impact block 431. In the actual application process , which has certain progress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com