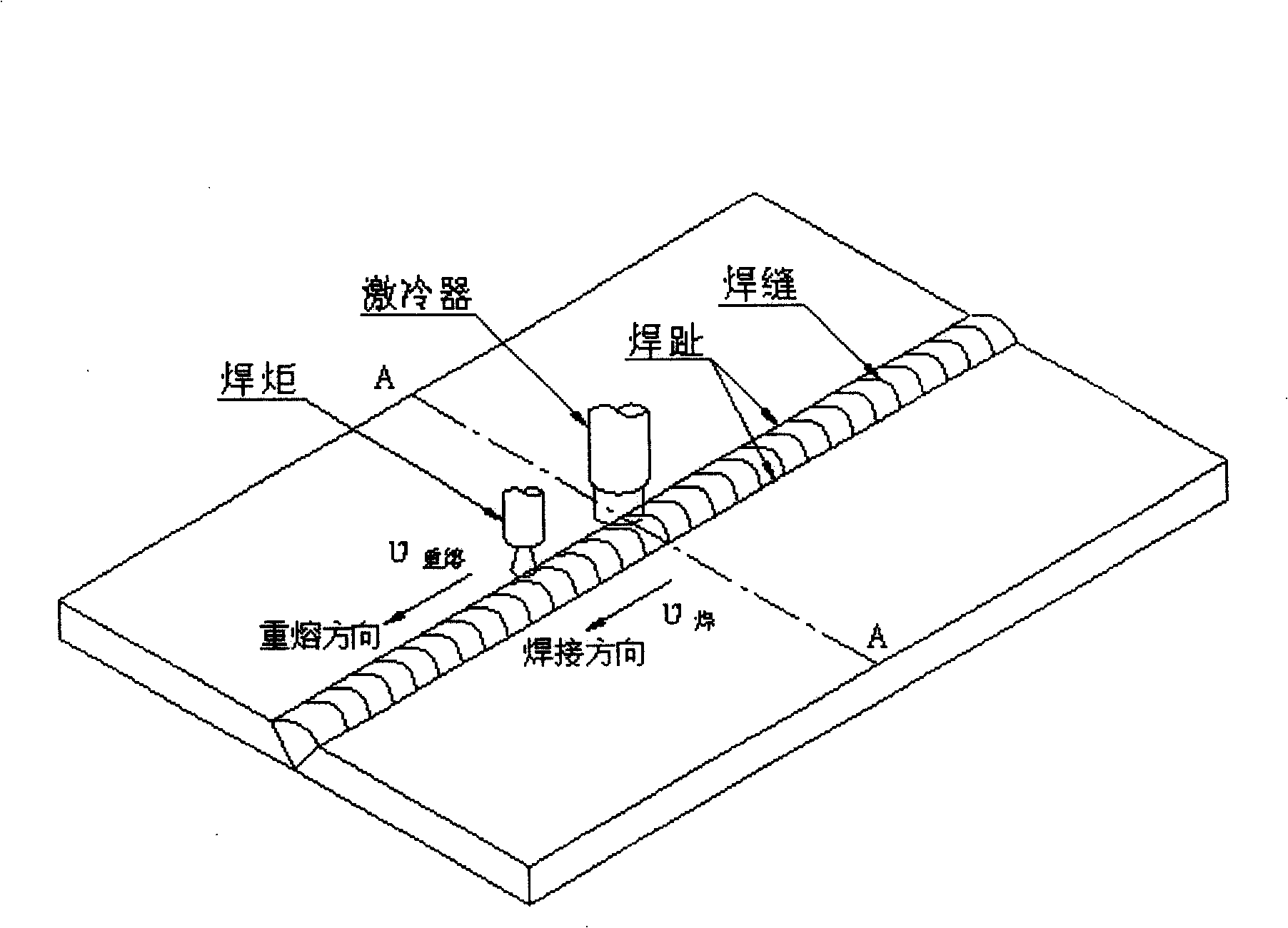

Method for improving welded joint fatigue strength following chilling treatment after weld toe TIG refusion

A technology for fatigue strength and welded joints, which is applied to the welded structure of low-alloy steel, low-carbon steel, and post-weld treatment. The effect of wide range, lower energy consumption, lower manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Chilling treatment process after TIG remelting of welding toes of railway vehicle bogie welding frame T-shaped corner joints. The material is Q345-C low-alloy structural steel (thickness 14mm), welding toe TIG remelting process parameters: tungsten pole diameter φ3.2mm, nozzle diameter φ12mm, argon gas flow rate 10L / min, current 170-180A, voltage 14-18V, Speed 13~16cm / min. During TIG remelting, the angle between the welding torch and the vertical plate is about 30°, and the arc axis is located 1 to 1.5 mm outside the welding toe. Weld toe TIG remelting layer chilling treatment process: When the temperature of the welding toe TIG remelting layer drops to no less than 500°C, water flow with a certain pressure is sprayed onto the surface of the welding toe remelting zone through a special nozzle for chilling treatment. Keep an appropriate distance from the TIG welding torch to ensure that the temperature of the remelting layer at the spraying position is not lower than ...

Embodiment 2

[0024] Chilling treatment process after TIG remelting of weld toe of plate butt joint. 16MnR low-alloy steel (thickness 14mm) was selected as the material, and the technological parameters of the TIG remelting of the weld toe and the chilling treatment of the remelting layer were the same as those in Example 1. During TIG remelting, the torch welds the test plate vertically, and the arc axis is located 0.5-1.0mm outside the welding toe. The residual stress test results are: in the welded state, σx = 215MPa, σy = 164MPa; after TIG remelting of the welding toe, σx = 155MPa, σy = 129MPa; after TIG remelting of the welding toe, spraying treatment when cooling to 550°C, σx = -209MPa, σy=-198MPa. It can be seen that after treatment by this process, a bidirectional compressive stress field that is conducive to improving fatigue strength is also formed in the weld toe area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com