High-frequency pulse current assisted surface shot blasting reinforcement machining device and method

A high-frequency pulse current and shot peening technology, which is used in the field of metal surface strengthening and surface strengthening of complex parts to achieve the effect of improving the degree of hardening, avoiding oxidation, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

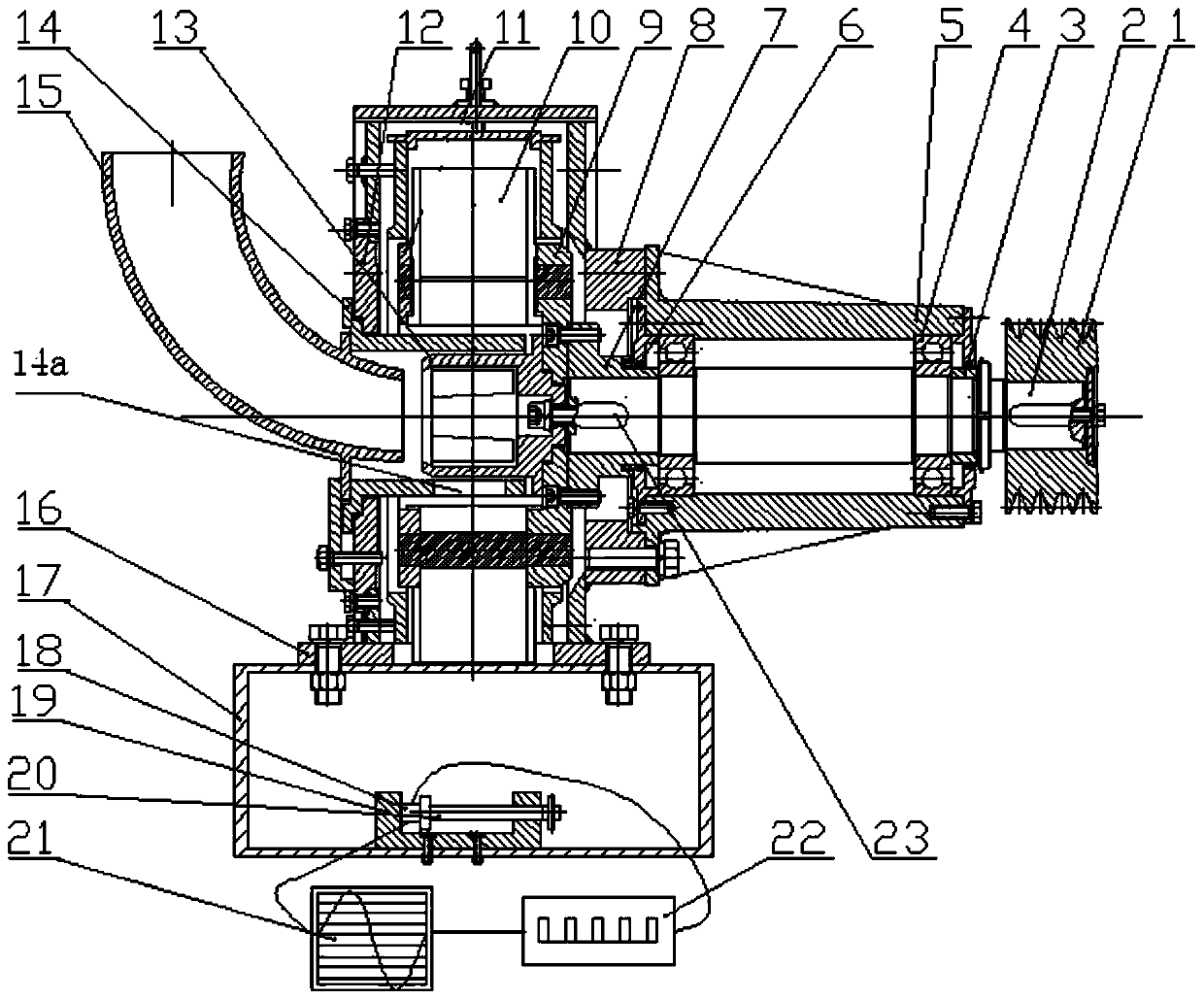

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] see figure 1 , a kind of high-frequency pulse current assisted surface shot peening processing device shown in the figure is made up of surface shot peening device and pulse power supply device; said surface shot peening device includes a shot peening chamber 17 and passes through base plate 16 Be installed on the shot-peening chamber 17 and spray into the shot-peening mechanism of shot-peening in the shot-peening chamber 17 and one is arranged on in the shot-peening chamber 17 in order to fix the workpiece clamping mechanism of workpiece 18; A pulsed current is applied to the workpiece 18 across the workpiece 18 .

[0026] The workpiece clamping mechanism is a vise, which has no difference from the existing vise, and also includes a vise body 19 and a vise screw mandrel 20 . The workpiece 18 can be clamped and loosened by rotating the vise screw 20 .

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com