A method and a system for evaluating fatigue reliability of a weld seam of a rail vehicle body

A rail vehicle and reliability technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems that cannot be directly applied to multiaxial fatigue strength evaluation of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

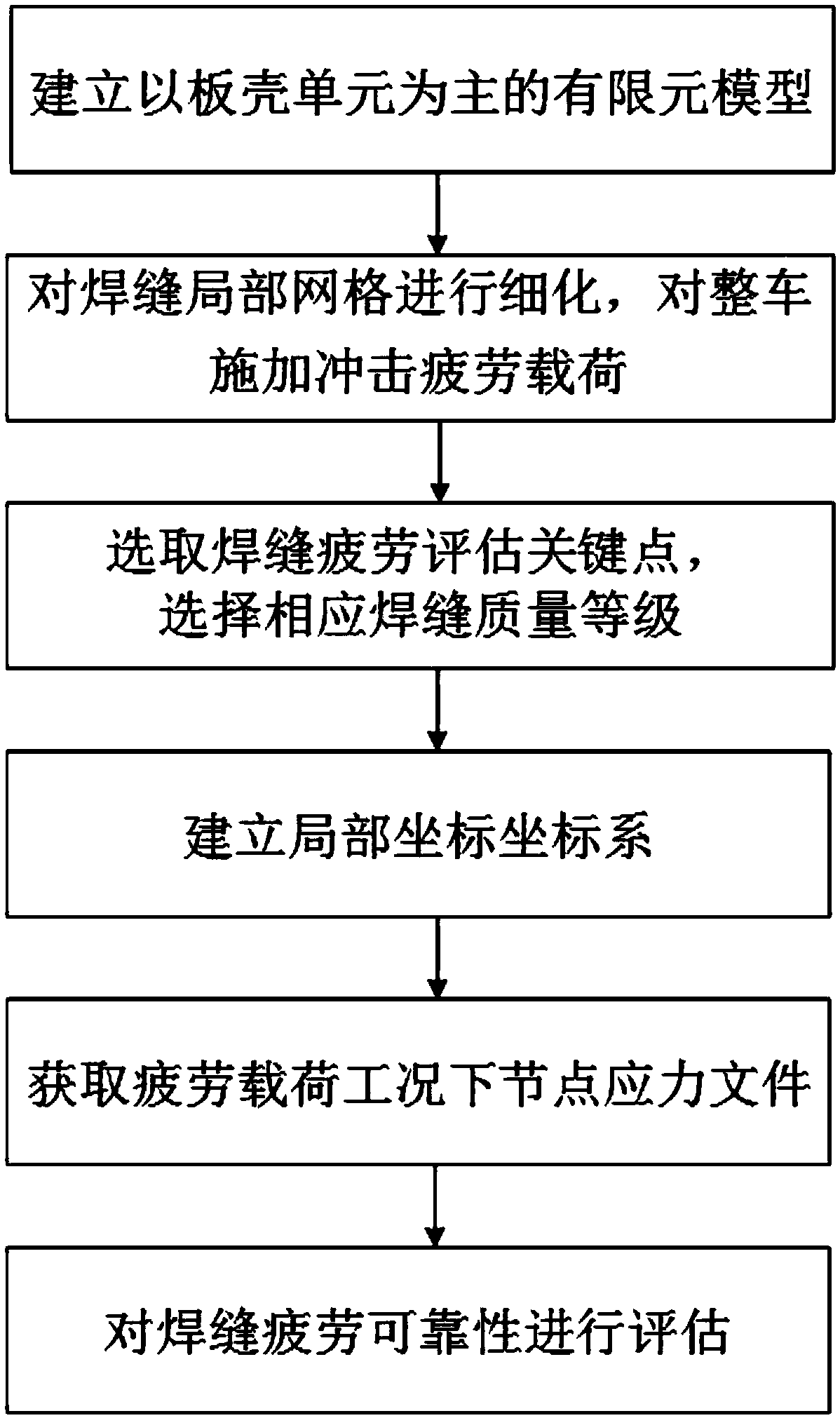

[0047] The invention relates to a method for evaluating the fatigue reliability of rail vehicle body welds, such as figure 1 As shown, the method includes the following steps:

[0048] Step 1. According to the three-dimensional geometric model of the car body, Hypermesh is used to establish a finite element model mainly composed of plate and shell elements, and the joint connection method of common nodes is used to simulate the welding between car body profiles or plates.

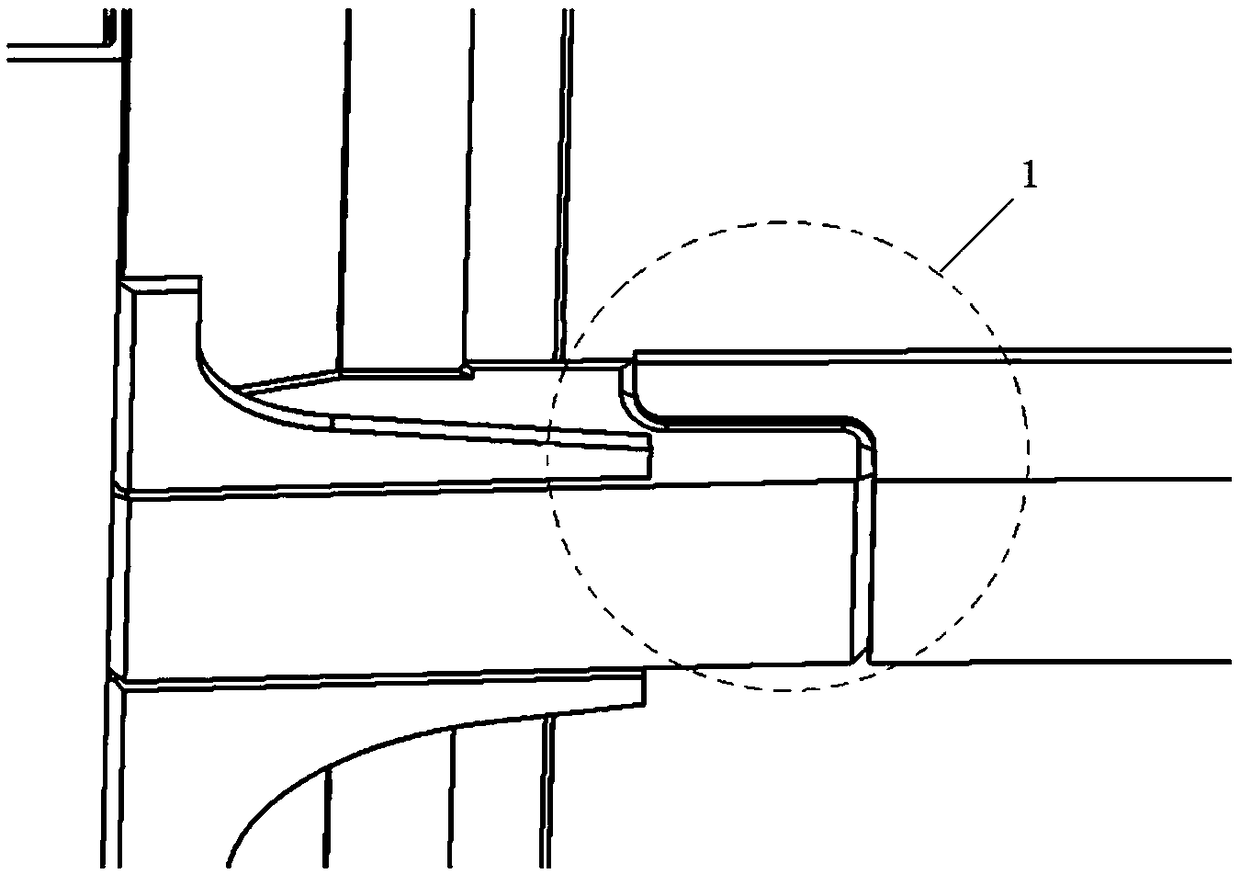

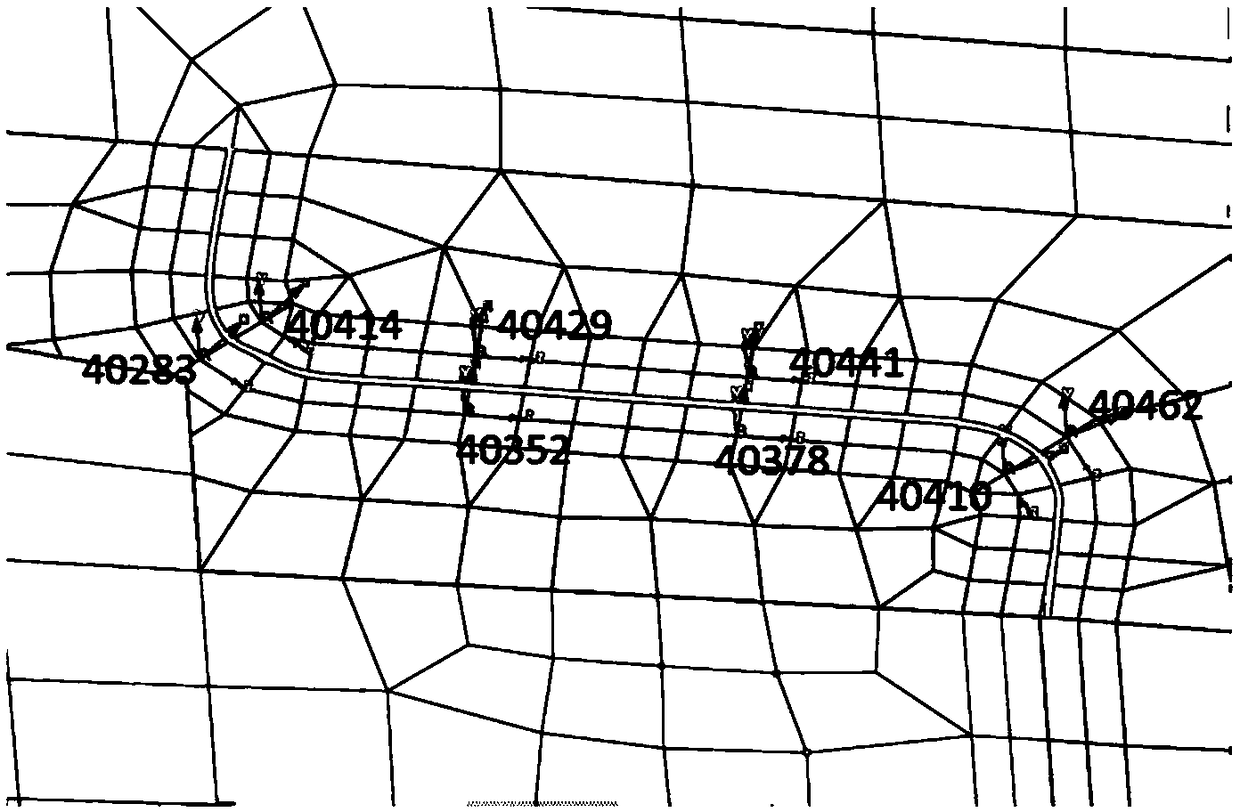

[0049] Step 2: refine the local mesh of the weld as required, and apply impact fatigue load to the vehicle.

[0050] Step 3: Determine the position of the weld seam on the car body, select key points for fatigue assessment of the weld seam, and select the corresponding weld seam quality grade according to the actual weld seam form and gap state.

[0051] Step 4: At the evaluation key point, take the direction parallel to the weld seam as the X axis, perpendicular to the weld seam, and establish a local coord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com