Method for testing high-frequency fatigue characteristic of material under microscale

A technology of fatigue characteristics and testing methods, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, and can solve problems such as analysis, anti-pitting corrosion, low resistance to local damage, and micro-fatigue characteristics that have not yet appeared

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

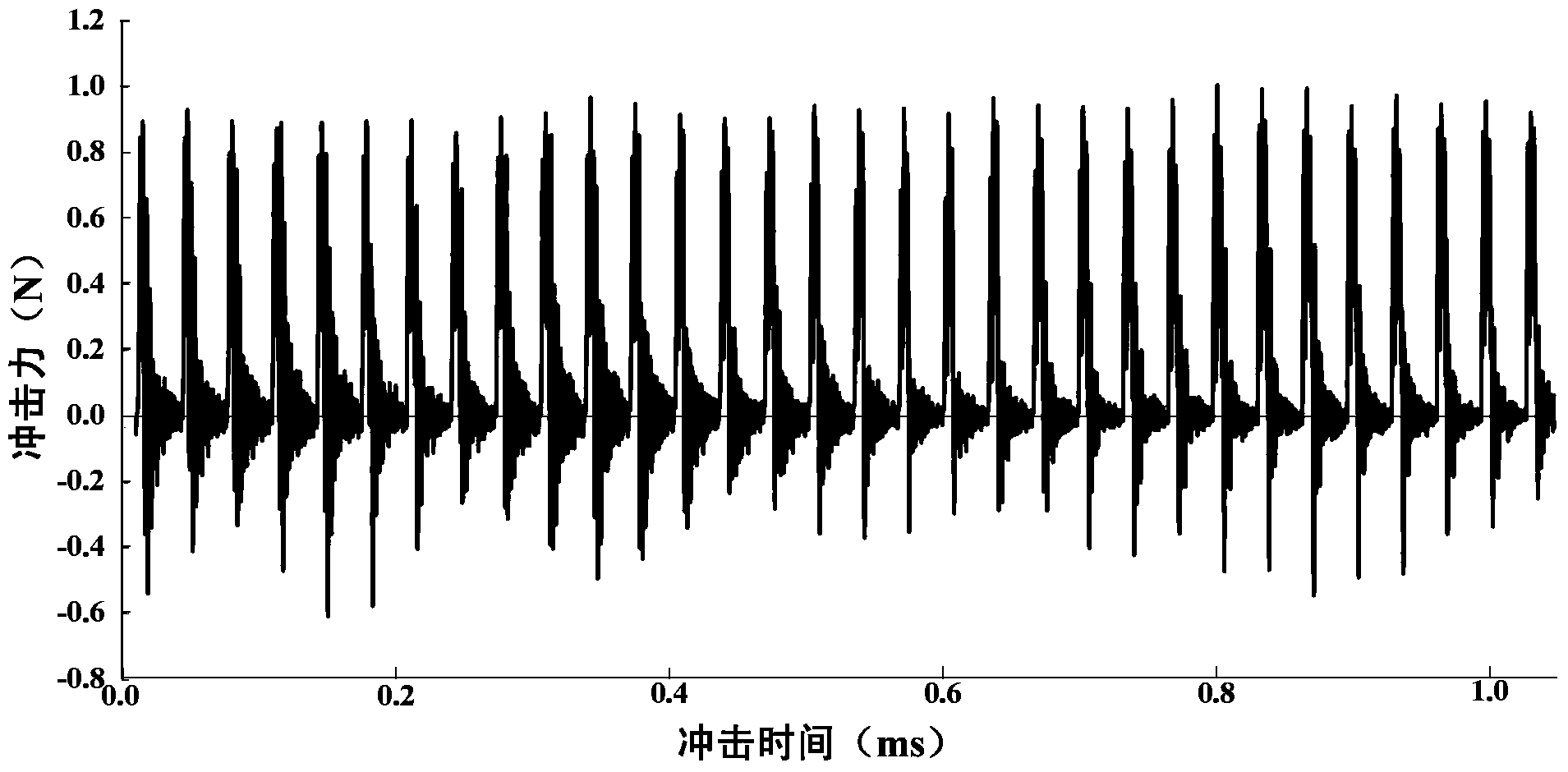

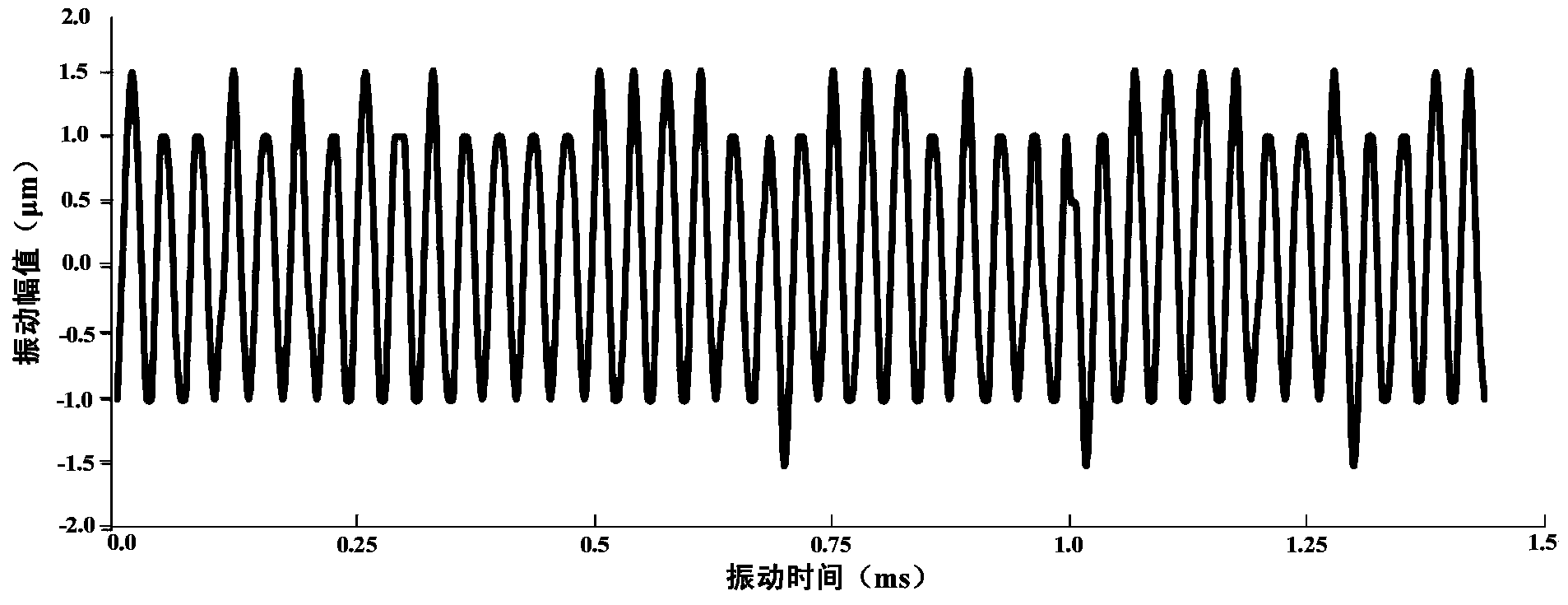

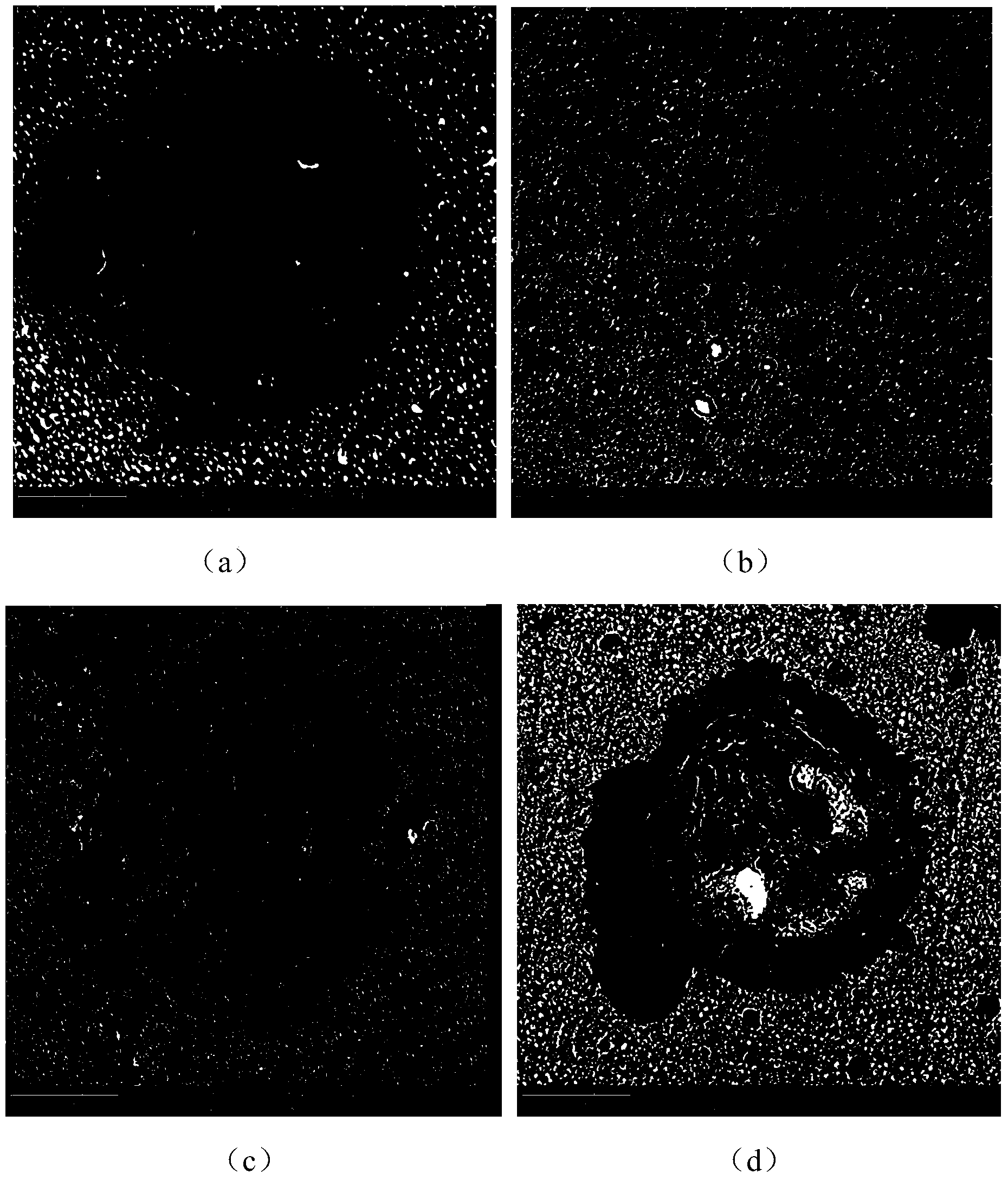

[0023] (1) Connect one end of the cermet tool (mainly composed of TiC) firmly to an ultrasonic vibration generating device, and make the other end contact with a fixed diamond indenter, which is connected with a high-precision force measuring system connected, the contact state between the diamond indenter and the sample passes the contact force critical value N crit Judgment, the contact force critical value N crit 0.01N, the shape of the diamond indenter is a circle with a round head, the radius R of the round head is 0.2mm, and the cone angle θ is 90°; the high-precision force measuring system includes Kistler9256C2 force measuring instruments connected in sequence , charge amplifier, data acquisition card and computer. The basic parameters of the high-precision force sensor are: the force measurement range is -20 ~ 20N, the force measurement accuracy is higher than 0.002N, and the natural frequency is less than 5kHz or greater than 50kHz to avoid resonance frequency; The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com