Device for testing bending fatigue of oil casing under complex load

A composite load and bending fatigue technology, which is applied in the direction of testing the strength of materials by applying a stable bending force, can solve problems such as fatigue, and achieve the effect of reducing performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

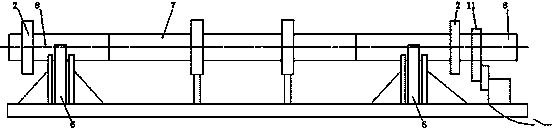

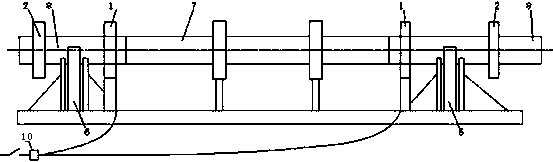

[0023] Embodiment: the concrete operating steps of the present invention are:

[0024] 1) Determine the mass of the bending load weight 2 according to the size of the sample 7;

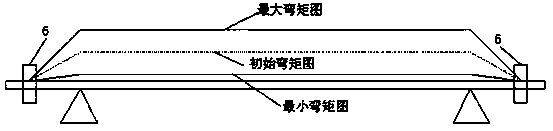

[0025] 2) If there is no internal pressure and axial load, press figure 2 The first-order bending natural frequency of the structural analysis shown;

[0026] 3) Adjust the power supply change frequency of the control power supply according to 3 / 5 of the frequency calculated in the second step, and drive the sample to rotate;

[0027] 4) Monitor the change of bending displacement until it is stable;

[0028] 5) If the bending displacement cannot reach the required value after stabilization, gradually increase the motor speed and monitor the change of displacement;

[0029] 6) When the bending displacement reaches the required value, stabilize the rotation speed and start the rotation bending fatigue test;

[0030] 7) When the sample undergoes fatigue fracture or the number of cycles reaches the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com