Large-scale dynamic load member fatigue performance testing method

A technology of fatigue performance and testing method, which is applied in the testing of machine/structural components, testing of mechanical components, measuring devices, etc. It can solve the problems that large-scale dynamic load components cannot be tested, and achieve the effect of low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] By adopting the method of the invention and using a conventional testing machine, the fatigue performance test is carried out on the rotor magnetic pole and the magnetic yoke of the pumped storage generator motor.

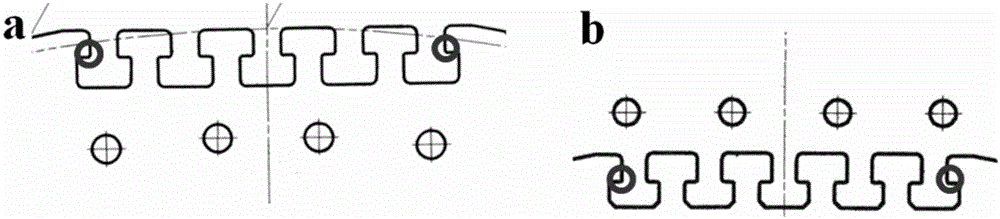

[0028] Magnetic poles and yokes are important parts of the rotor components ( figure 1 As shown), the magnetic pole is the basic element that constitutes the field winding, and is the magnetic induction component for the generator to establish a rotating magnetic field. The yoke is a yoke iron made of silicon steel sheets. On the one hand, it constrains the magnetic field lines generated by the induction coil to scatter outwards, and on the other hand, it acts as a magnetic shield. The magnetic pole and the yoke have a conjugated dovetail or T-tail structure, and the magnetic pole is fixed on the yoke through the magnetic pole key. The specific test process of the two components is as follows:

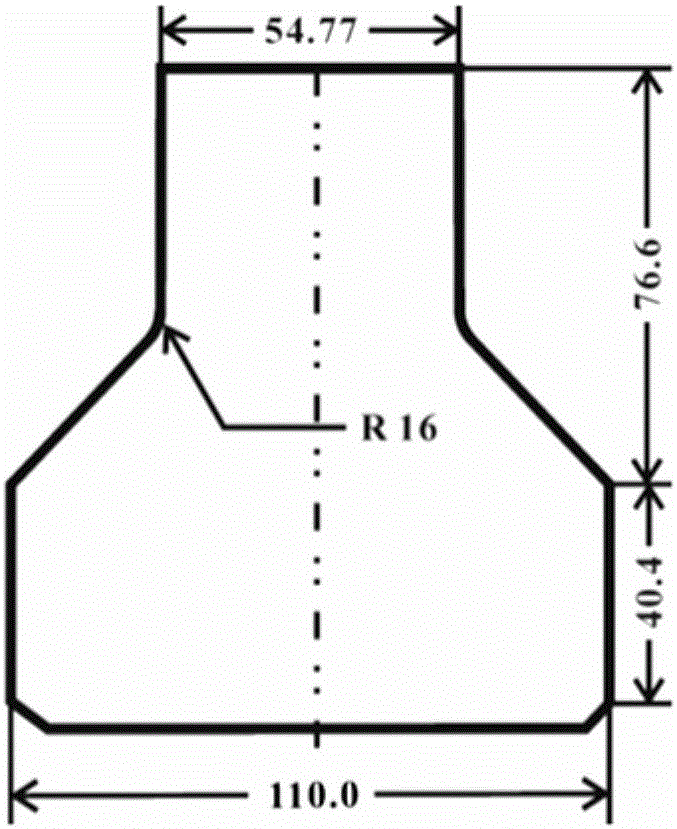

[0029] (1) Determine the most dangerous point of the rotor pol...

Embodiment 2

[0040] Difference with embodiment 1 is: the specific process of step (5) is different, and the present embodiment process is as follows:

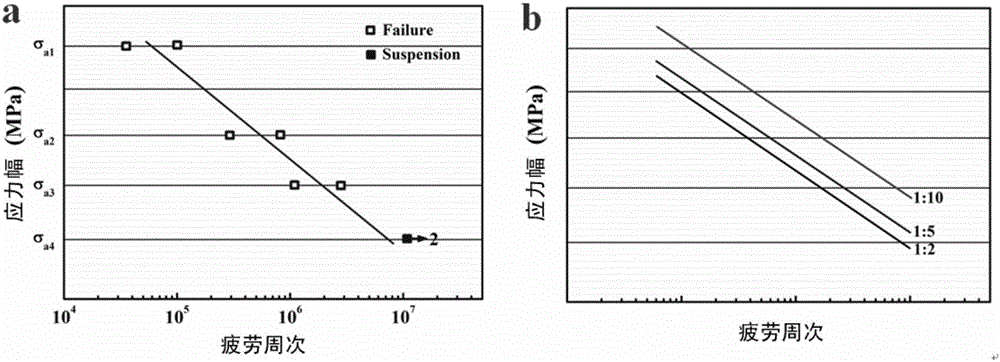

[0041] Calculate the load spectrum of service components under different working conditions (such as the start and stop of magnetic poles and yokes, load shedding and runaway) through finite element software, and then select the working conditions with more serious damage as the loading stress amplitude of miniature components (such as 150MPa~0.01MPa), and at least two miniature components with different ratios are selected for fatigue tests, and the quantitative relationship between the scaling ratio (1:2, 1:5 and 1:10) and the fatigue life of miniature components with different ratios is established (such as Figure 5 shown), and calculate the fatigue life of the service components by reasonable extrapolation (such as Figure 5 Points in , assuming that the logarithmic coordinates in the figure are linear).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com