Plastic particle smashing, screening and drying device

A technology of drying device and plastic particles, applied in the field of plastic processing, can solve the problems that the screening and pulverizing device has no drying effect, it is difficult to ensure the degree of drying of particles, and it is difficult to ensure the degree of drying, and achieves simple structure, energy saving, The effect of improving the crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

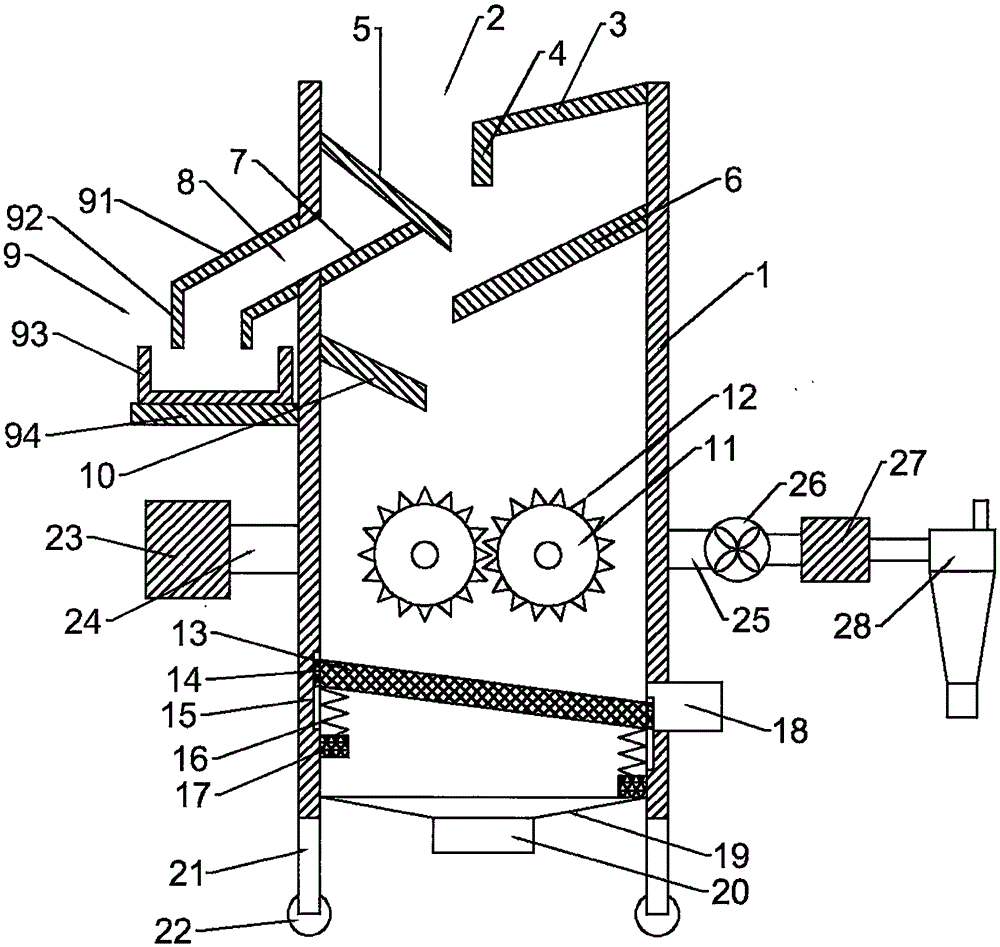

[0014] see figure 1 A crushing, screening and drying device for plastic particles, comprising a body 1, the upper end of the body 1 is provided with a feed port 2, the feed port 2 is provided with a first inclined plate 3 inside the body 1, the first inclined plate 3 The bottom is connected with a riser 4, the left side of the riser 4 is provided with a filter screen 5 installed inside the body 1, a second slant plate 6 is provided below the riser 4, a third slant plate 7 is provided below the filter screen 5, A through hole 8 is opened on the left surface of the body 1, and a recovery device 9 fixed on the outer wall of the body 1 is arranged below the through hole 8. The recovery device 9 includes a first recovery tube 91, and a second recovery tube 91 is connected below the first recovery tube 91. Pipe 92, below the second recovery pipe 92, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com