Screening bucket of excavator

An excavator and screening technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, screens, etc., can solve the problems of single function of the screening bucket and inability to screen multiple times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

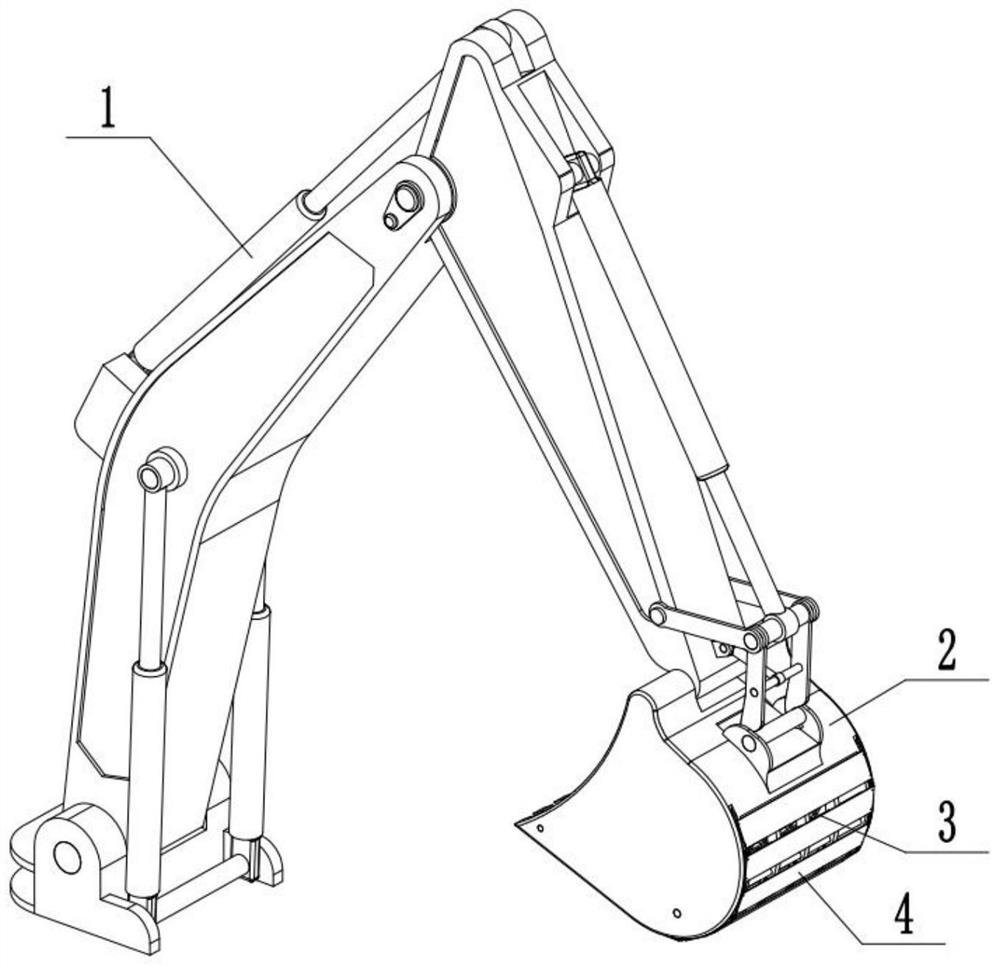

[0029] Combine below Figure 1-12In this embodiment, an excavator screening bucket includes a machine arm assembly 1, an excavator bucket 2, a screening bucket assembly 3, and an adjustable screening plate assembly 4. The machine arm assembly 1 and The excavator bucket 2 is connected, the excavator bucket 2 is connected with the screening bucket assembly 3, the excavator bucket 2 is connected with the adjustable screening plate assembly 4, the screening bucket assembly 3 is connected with the adjustable screen The sub-board assembly 4 is connected.

specific Embodiment approach 2

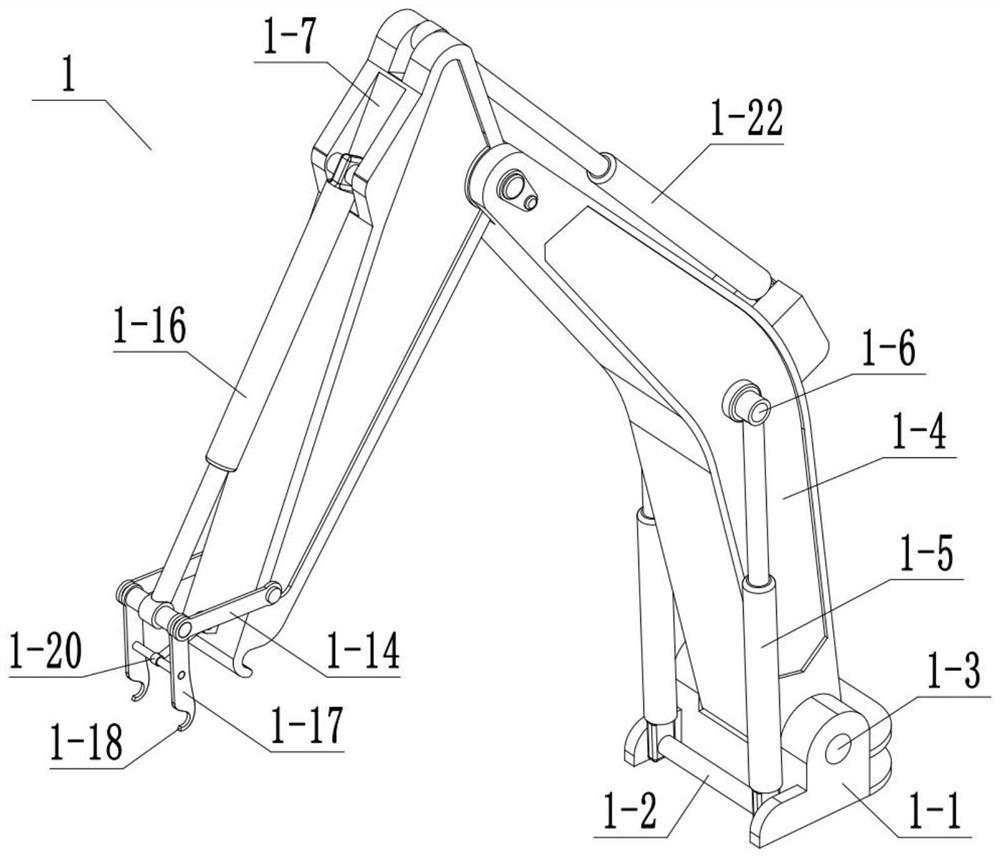

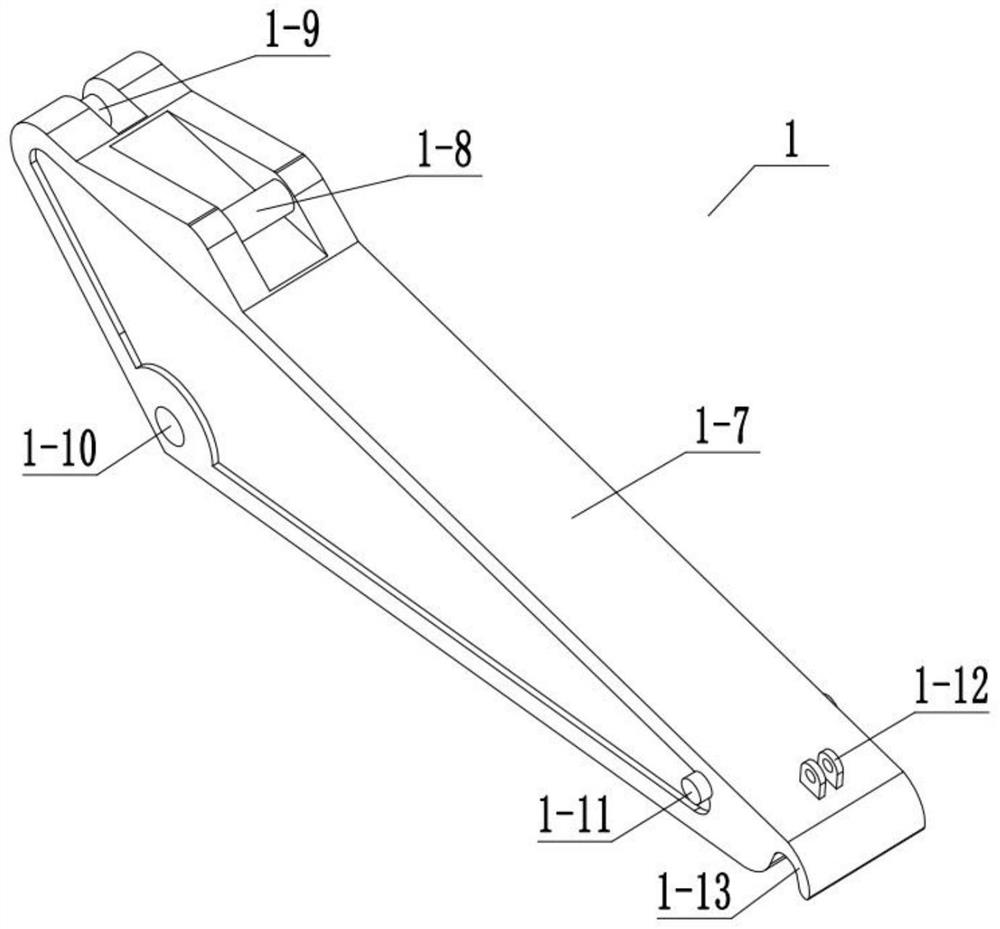

[0031] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the first embodiment, the arm assembly 1 includes a base 1-1, a support rod 1-2, a rotating shaft 1-3, a boom 1-4, and a boom cylinder 1-5, rotating shaft 2 1-6, stick 1-7, rotating shaft 3 1-8, rotating shaft 4 1-9, hole 1 1-10, rotating shaft 5 1-11, lug 1 1-12, arc hook One 1-13, connecting rod one 1-14, pin one 1-15, bucket cylinder 1-16, connecting rod two 1-17, arc hook two 1-18, pin two 1-19, loading bucket Oil cylinder 1-20, pin shaft 3 1-21, arm cylinder 1-22, base 1-1 is fixedly connected with support rod 1-2, base 1-1 is rotationally connected with swing arm 1-4 through rotating shaft 1-3 , the support rod 1-2 is rotationally connected with the boom cylinder 1-5, the boom 1-4 is rotationally connected with the boom cylinder 1-5 through the second rotating shaft 1-6, and the boom 1-4 is connected with the stick 1-7 through the hole One 1-10 rotating connection, boom 1-4...

specific Embodiment approach 3

[0034] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the first embodiment, the excavator bucket 2 includes a bucket body 2-1, spring lug one 2-2, motor seat 2-3, hole two 2-4 , outer raceway 2-5, inner raceway 2-6, fixed support shaft 2-7, fixed connecting rod 2-8, rib 2-9, water inlet 2-10, nozzle 2-11, rotating shaft six 2-12 , pin three 2-13, pin four 2-14, bucket body 2-1 is provided with spring lug one 2-2, motor seat 2-3, hole two 2-4, outer raceway 2-5 , inner raceway 2-6, bucket body 2-1 is fixedly connected with fixed support shaft 2-7, fixed connecting rod 2-8, rib 2-9, pin three 2-13, pin four 2-14, The bucket body 2-1 is rotationally connected with the shaft six 2-12, the rib 2-9 is provided with a water inlet 2-10, the rib 2-9 is fixedly connected with the nozzle 2-11, the bucket body 2-1 is connected with the arm 1 -7 is rotationally connected by circular arc hook 1 1-13 and pin shaft 3 2-13, bucket body 2-1 and conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com