Wear-resistant aluminum alloy sheet metal part

A technology for aluminum alloy and sheet metal parts, applied in the field of sheet metal parts, can solve the problems of high cleaning cost and difficulty in cleaning, and achieve the effect of ingenious structure, reduced impact and enhanced service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

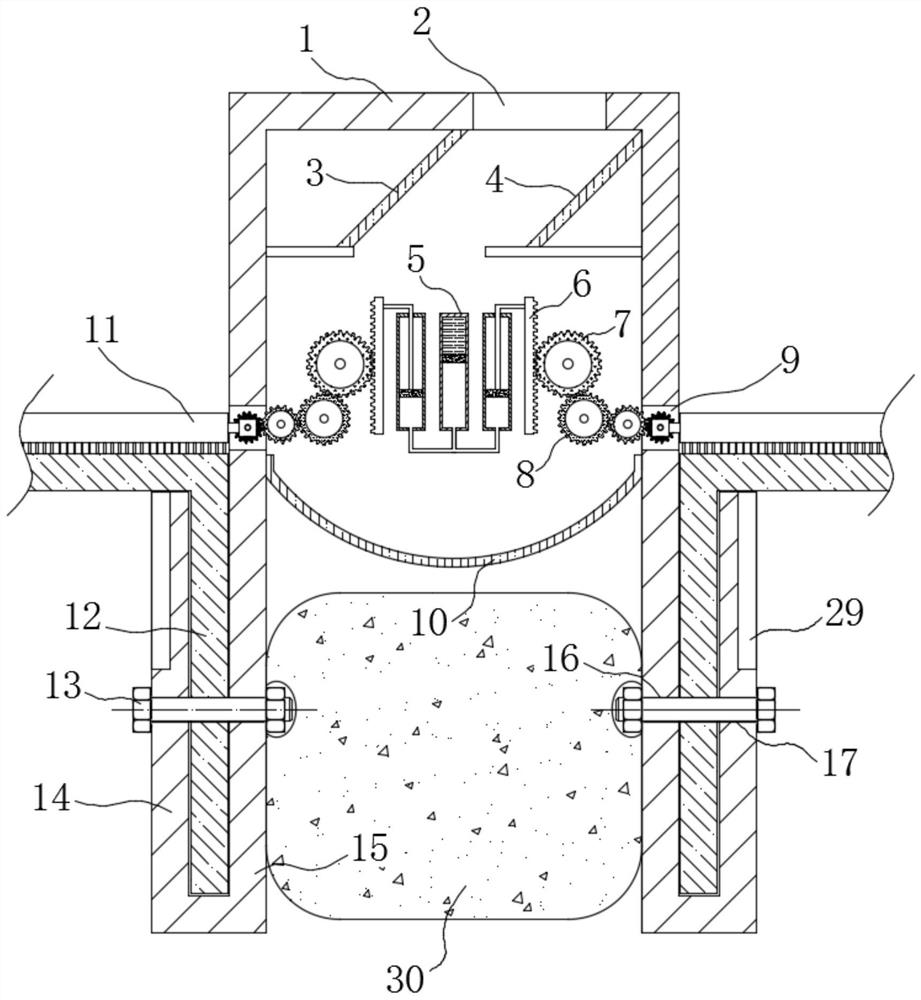

[0035] As an embodiment of the present invention, the angles between the first plane light emitting mirror 4 and the second plane light emitting mirror 3 and the horizontal plane are both 45°, which can realize the conversion between vertical light and horizontal light;

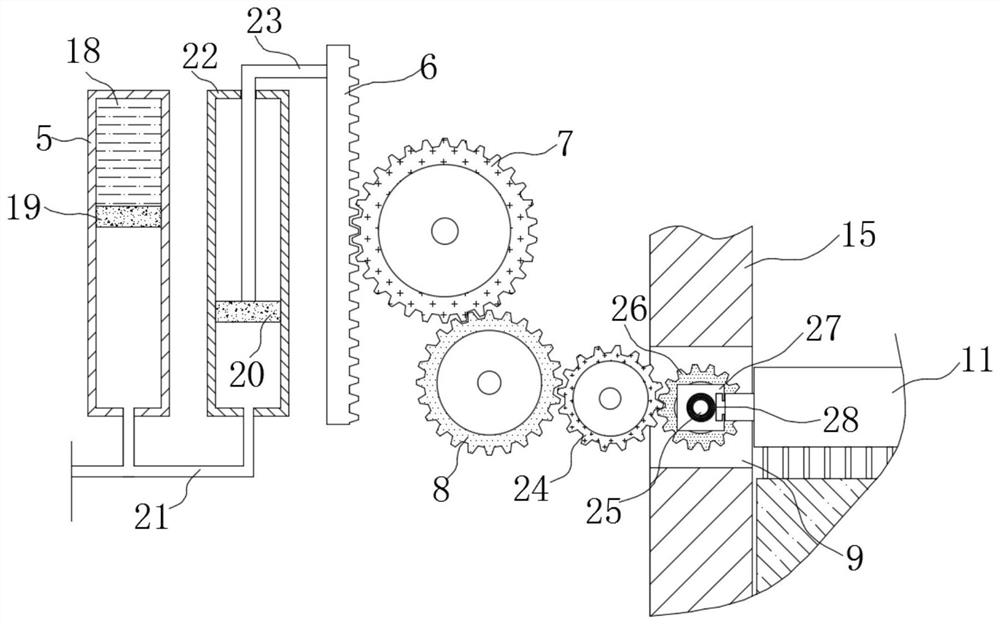

[0036] As an embodiment of the present invention, the inspiration mechanism includes a storage tube 5 located at the focal point of the concave reflector 10, a first piston 19 is installed inside the storage tube 5, and the first piston 19 is connected to the storage tube 5. An evaporating liquid 18 is provided in the airtight area formed by the tube 5, and the evaporating liquid 18 can be chloroform (boiling point is 61.3° C.);

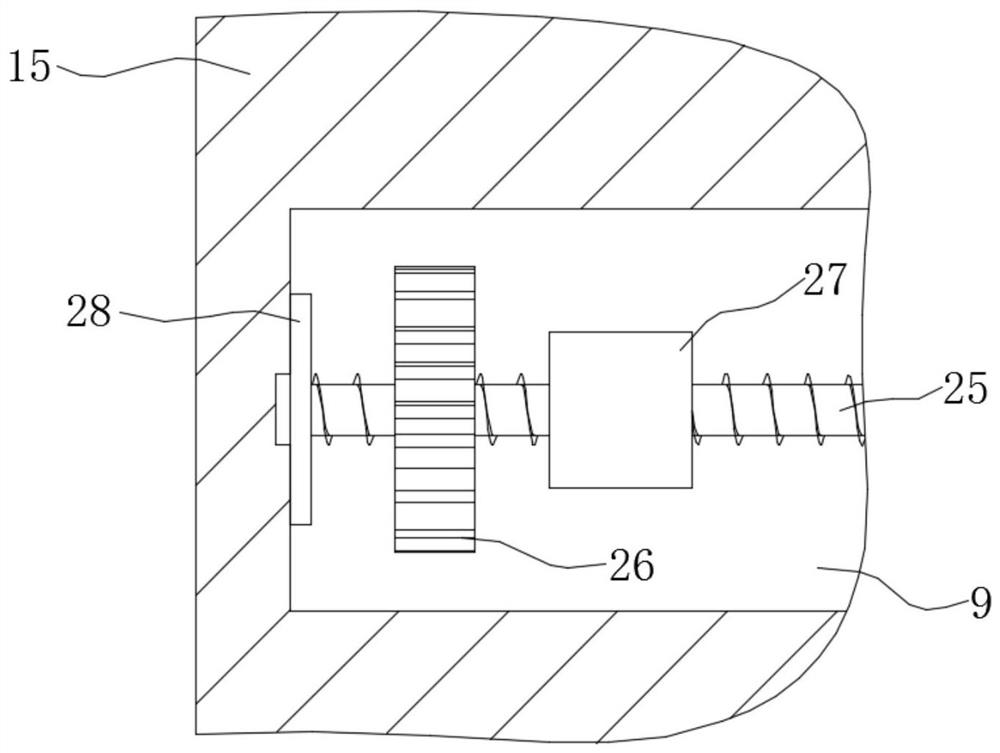

[0037] The inspiration mechanism also includes two sealing tubes 22 symmetrically arranged at both ends of the containing tube 5, and each sealing tube 22 is communicated with the containing tube 5 through a communication tube 21, and each sealing tube 22 is provided with The second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com