Axial crusher

A pulverizer, axial technology, applied in the direction of grain processing, etc., can solve the problems of difficult control of material crushing effect, poor material crushing effect, large power consumption, etc., to increase the number of moving knife groups and fixed knives, and improve the crushing efficiency. effect, the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

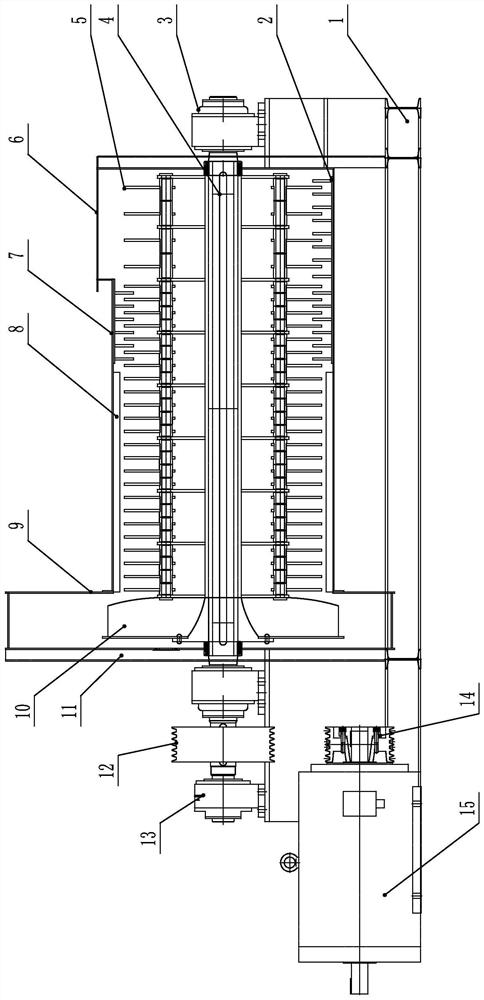

[0027] Embodiment 1: An axial pulverizer, comprising a base 1, a fixed knife set 2, a rotor bearing 3, a pulverizing rotor 4, a moving knife set 5, a housing 7, a rubbing plate 8, a fan casing 9 and fan blades 10,

[0028] The middle part of the upper surface of the base 1 is provided with a housing 7, and the middle part of one end surface of the housing 7 is provided with a through hole, the other end of the housing 7 is connected with the fan casing 9, and the two ends of the upper surface of the base 1 are provided with rotor bearings 3. The rotor 4 is arranged inside the housing 7 and the fan casing 9, and each end of the crushing rotor 4 is connected to a rotor bearing 3; the outside of the crushing rotor 4 is provided with multiple sets of moving knife sets 5 and fan blades 10; the fan blades 10 is set inside the fan casing 9; multiple sets of moving knife groups 5 are set inside the housing 7; one end of the housing 7 is surrounded by a plurality of fixed knife groups 2...

specific Embodiment approach 2

[0030] Specific embodiment two: described power unit comprises driven pulley 12, motor pulley 14 and motor 15; Wherein one end of crushing rotor 4 two ends passes through rotor bearing 3 and passes driven pulley 12; Described motor pulley 14 and The motor shaft of the motor 15 is connected, and the driven pulley 12 is connected with the motor pulley 14 by a belt.

[0031] Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0032] Specific embodiment three: one of the two ends of the pulverizing rotor 4 passes through the rotor bearing 3 and the motor pulley 14 and then passes through the supporting bearing 13;

[0033] The support bearing 13 is arranged on the upper surface of the base 1 .

[0034] Other implementation manners are the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com