Prefabricated part full-automatic pouring device capable of raking materials

A prefabricated component, fully automatic technology, applied in the direction of supply devices, manufacturing tools, ceramic molding machines, etc., can solve the problems of low strength of concrete prefabricated parts, manual raking and vibrating, low pouring efficiency, etc., to improve the output and The effects of pouring efficiency, quality improvement and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

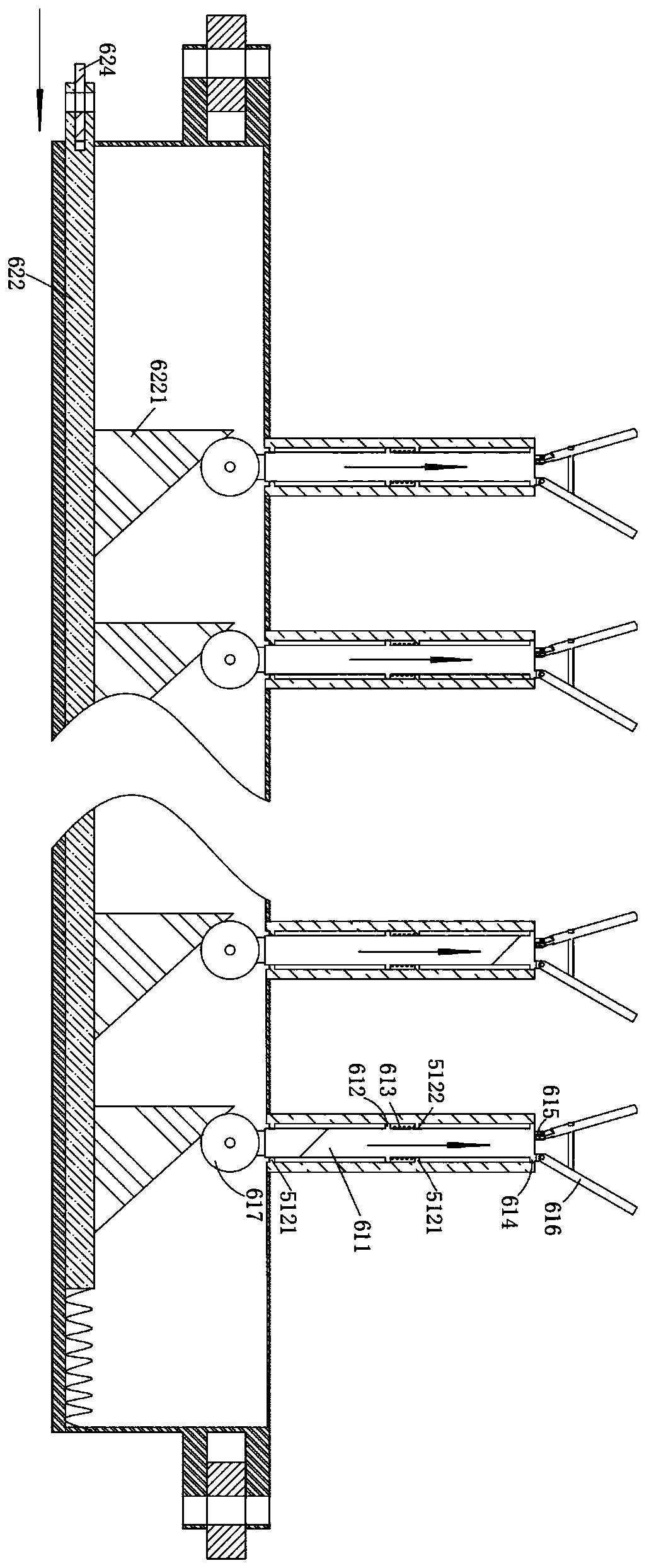

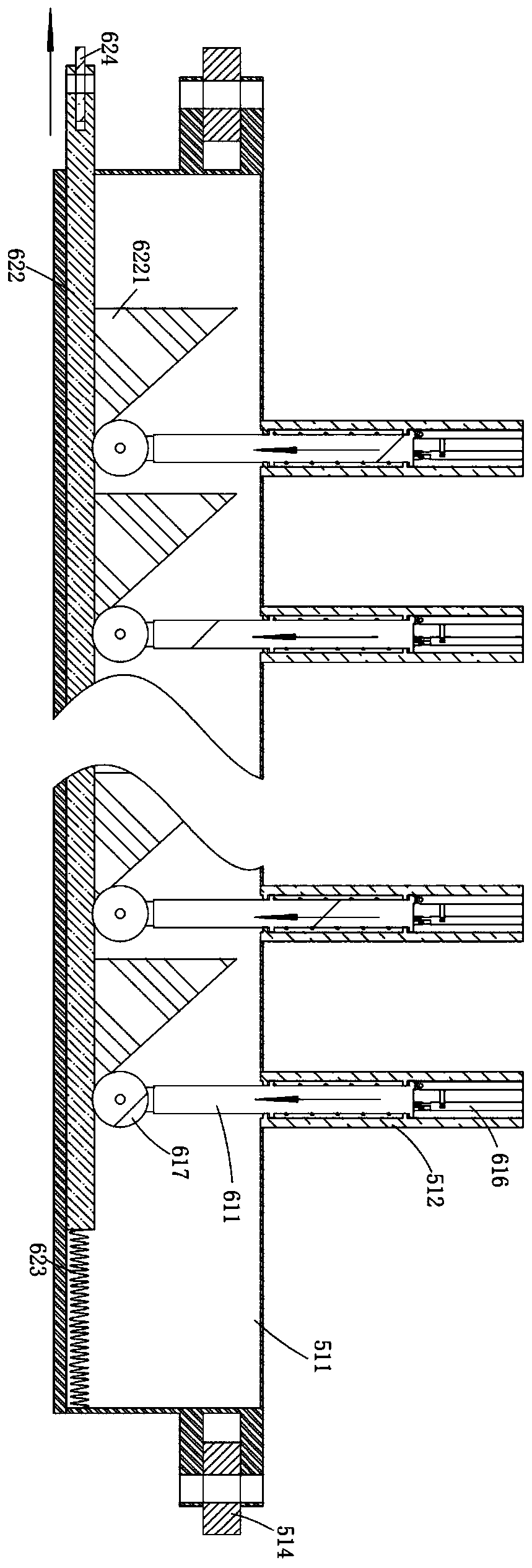

[0038] Such as Figure 7 and Figure 8 As shown, the present invention provides a prefabricated part pouring equipment, including a pouring platform 1, a pouring formwork 2 and a crane 3, and it is characterized in that it also includes:

[0039]Discharging device 4, said discharging device 4 includes a material storage box 41 fixed on said driving vehicle 3 and a rotating roller 42 that is rotatably mounted on said material storage box 41, and the concrete slurry rotates along said rotating roller 42 The direction flows from the discharge channel 43 formed between the storage box 41 and the rotating roller 42 to the pouring formwork 2;

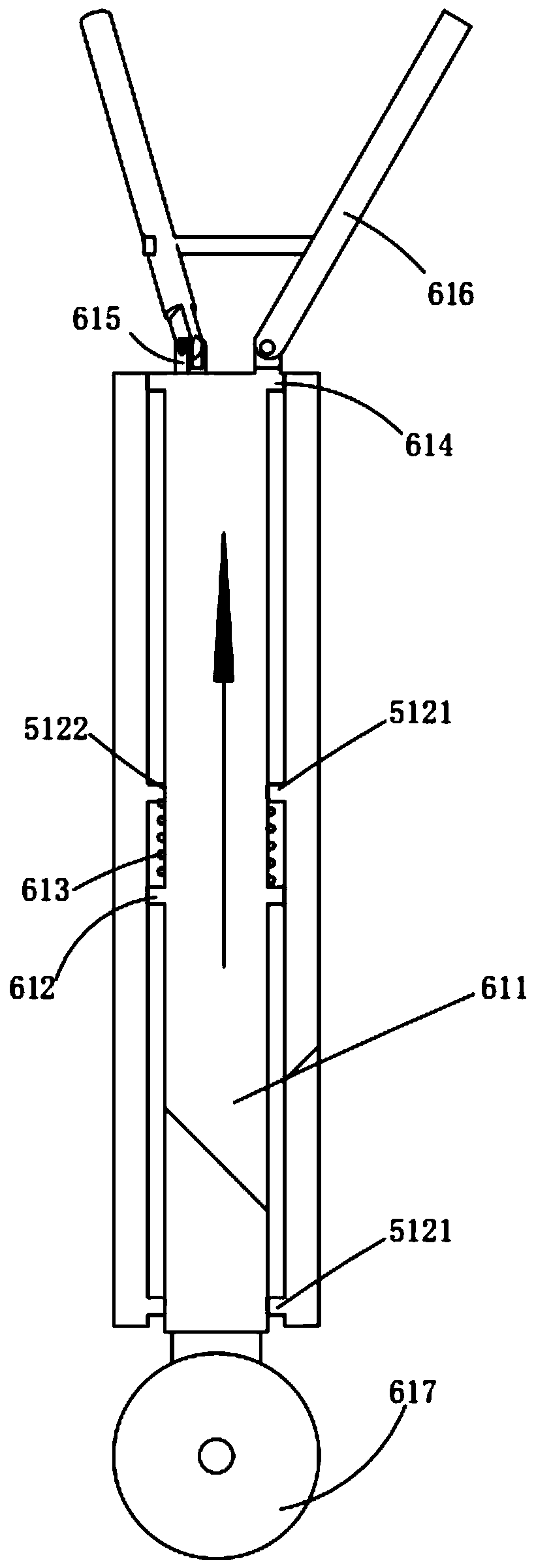

[0040] Material rubbing device 5, described rubbing material device 5 comprises rubbing material part 51 and control part 52, a plurality of described rubbing parts 51 circular arrays and on the described rotating roller 42, and described control part 52 is fixed on described storage box 41, and the two control parts 52 are arranged at both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com