Rotary bearing feeding device

A rotary and bearing technology, which is applied in rotary conveyors, transportation and packaging, and solid separation, can solve the problems of bearing quality damage and difficult control of feeding speed, and achieve improved bearing feeding level, simple structure, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

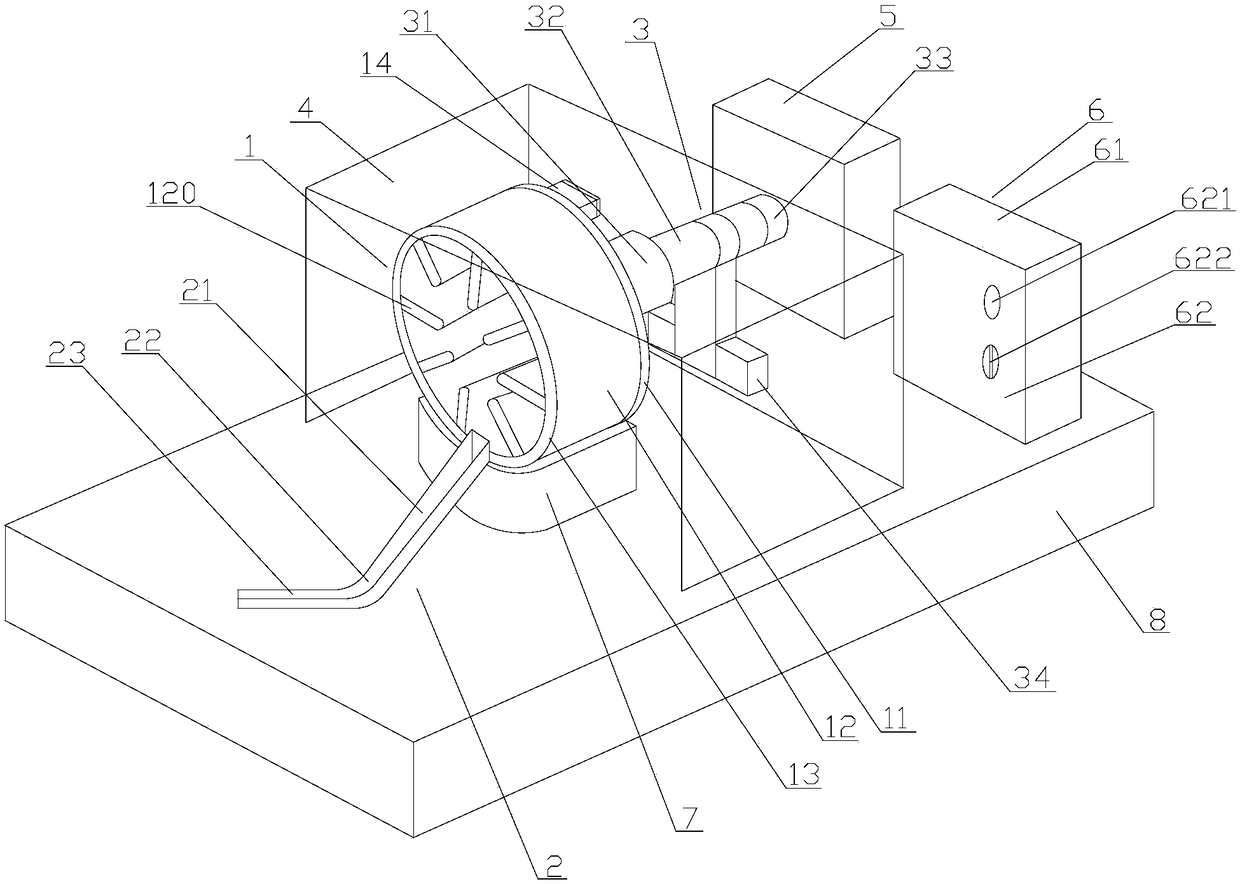

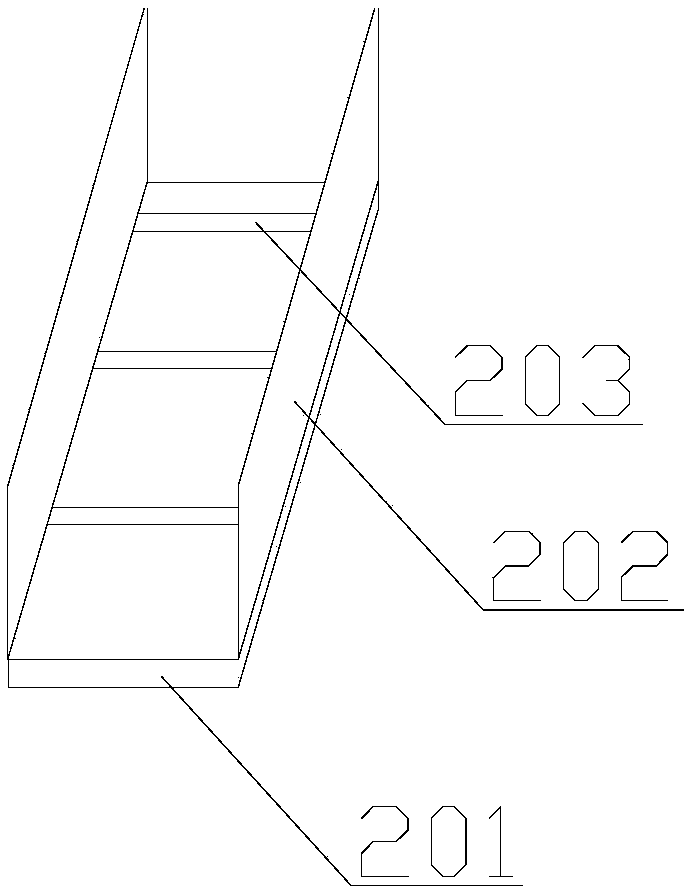

[0017] refer to figure 1 and 2 , a rotary bearing feeding device of the present invention, comprising a funnel 1, a chute 2, a rotating shaft 3, a protective cover 4, a motor 5, a control mechanism 6, a base 7, and a workbench 8, and a base 7 is provided below the funnel 1 , the base 7 is installed on the workbench 8, the outer side of the funnel 1 is provided with a protective cover 4, the funnel 1 is a hollow cylindrical structure, the chute 2 is connected to the inner side of the funnel 1, and the funnel 1 Rear side is provided with rotating shaft 3, and described rotating shaft 3 is connected with motor 5, and described motor 5 is installed on the workbench 8, and described workbench 8 is also provided with control mechanism 6, and described motor 5 and control mechanism 6 cooperate with each other , the funnel 1 includes a funnel bottom surface 11, a funnel barrel 12, a funnel front baffle 13 and a feed inlet 14, the funnel bottom 11 is fixed on the rear side of the funn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com