Automatic grain conveying and drying device for agriculture

An automatic conveying and drying device technology, applied in the agricultural field, can solve the problems of grain storage quality decline, grain not being dried, moldy, etc., to achieve the effect of improving efficiency and quality, fast drying, and avoiding moldy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

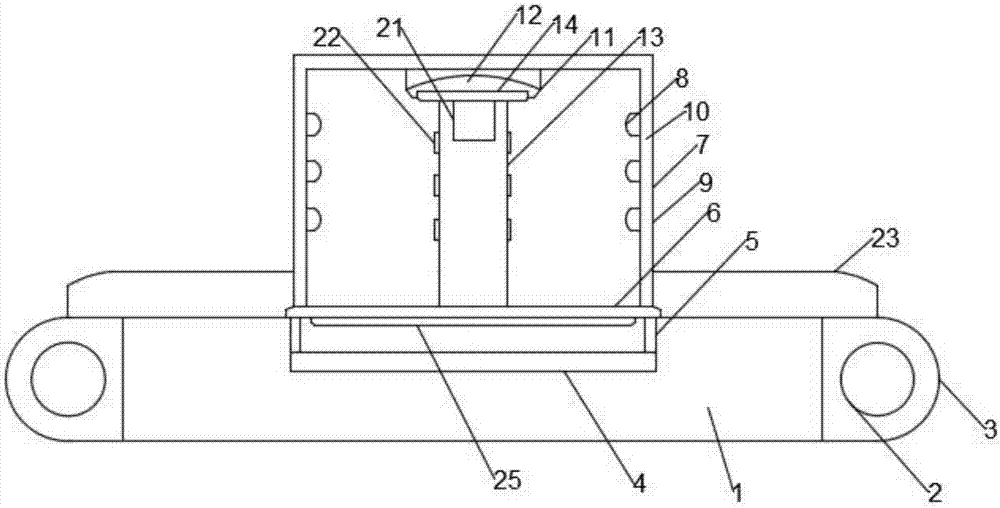

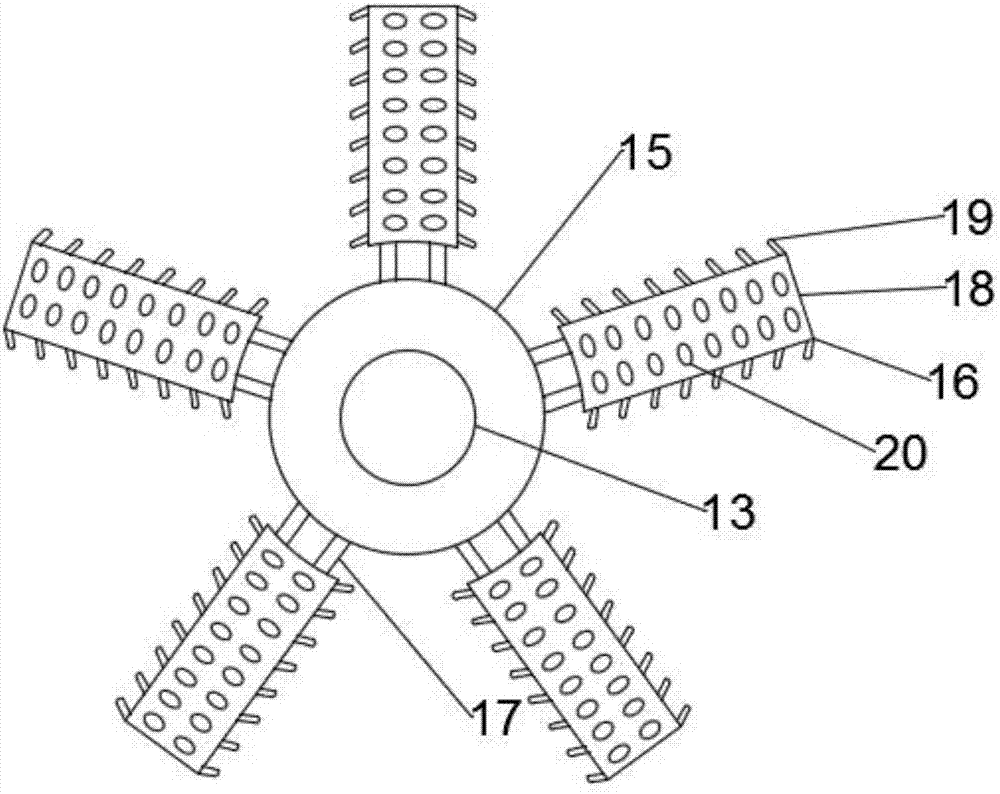

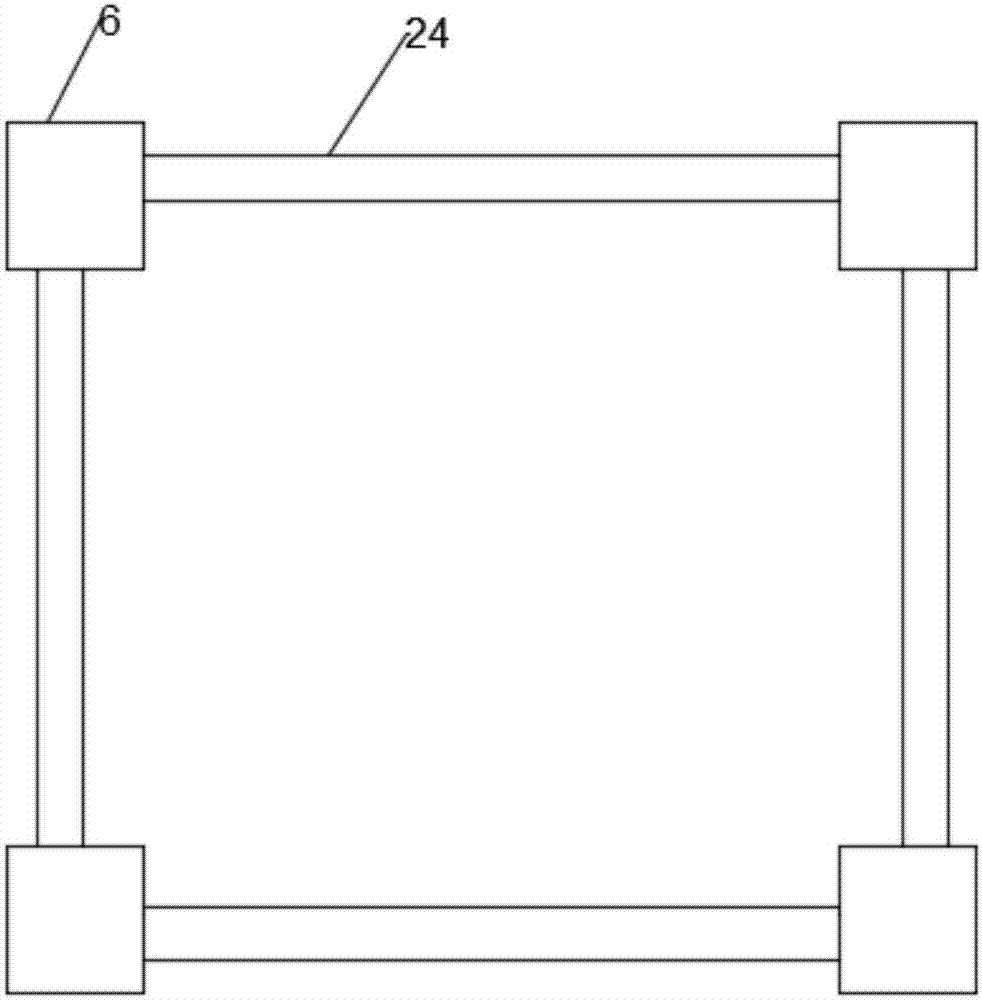

[0018] Such as Figure 1 to Figure 3 As shown, the present invention provides an automatic agricultural grain conveying and drying device, an automatic agricultural grain conveying and drying device, comprising a transport platform 1, the interior of the transport platform 1 is a hollow structure, and the interior of the transport platform 1 is Both ends are connected with a drive shaft 2, and the drive shaft 2 drives the transmission plate 3 on the surface of the transport platform 1 to rotate. The surface of the transmission plate 3 adopts a mesh structure, and the size of the mesh is smaller than the size of the grain. The transport platform 1 The upper surface is provided with an opening 25. During transportation, since the size of the mesh is smaller than the diameter of the grain, the grain will not fall to the opening 25. Meanwhile, impurities or debris smaller than the grain particles can fall through the opening. Fall into the interior of the transport platform 1, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com