A transport device for ore and rock crushing

A technology of transfer device and ore rock, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of slow unloading progress, increase the labor volume of workers, affect work efficiency, etc., to ensure uniformity, save screening time, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

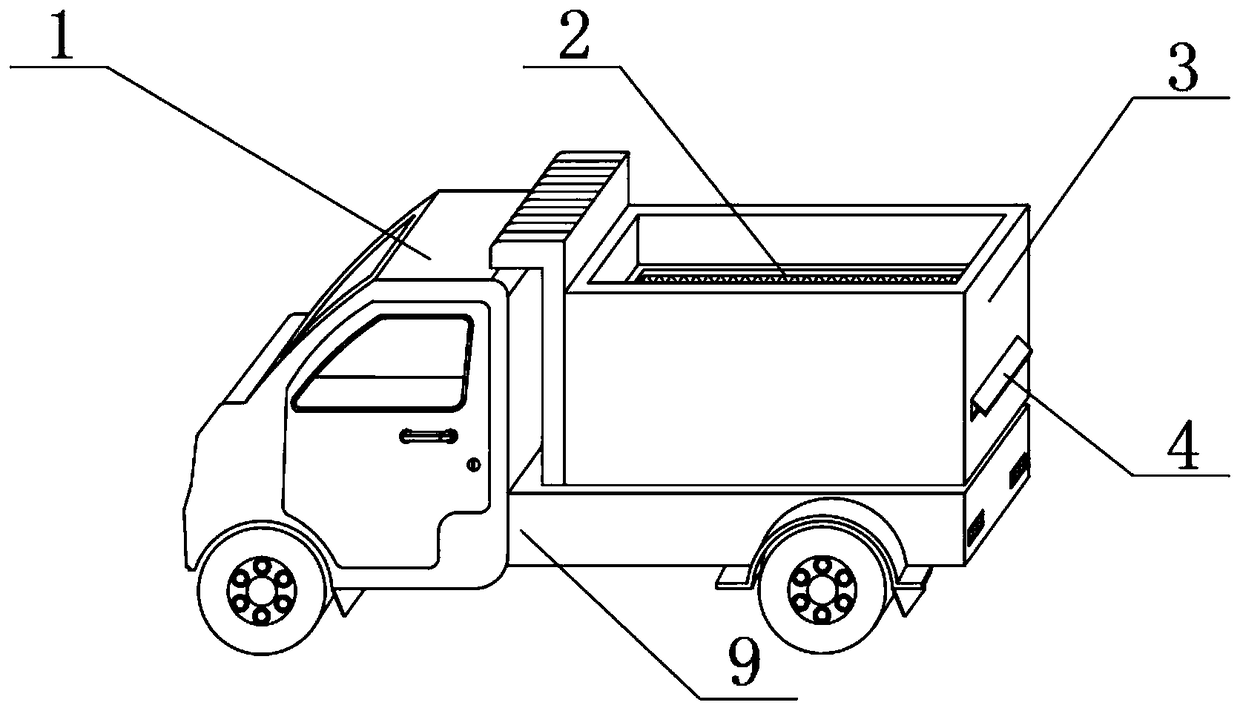

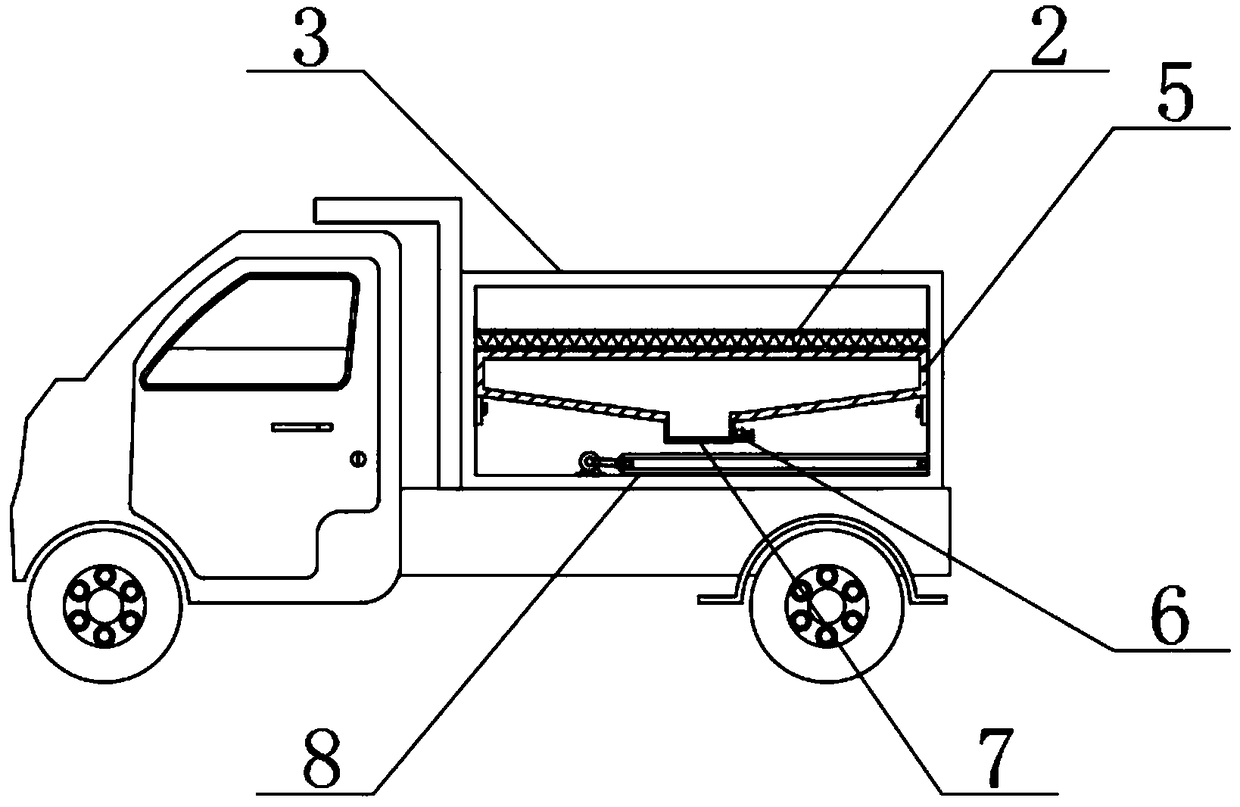

[0020] see Figure 1~4 , in an embodiment of the present invention, a transfer device for rock crushing includes a headstock 1, a vehicle frame 9 is arranged on one side of the headstock 1, a cargo compartment 3 is installed on the upper surface of the vehicle frame 9, and the inner side of the cargo compartment 3 is fixedly installed There is a screen 2, and the interior of the cargo compartment 3 is located below the screen 2, and a collection box 5 is fixed. The collection box 5 is in the shape of a rectangular funnel as a whole, and the collection box 5 is fixed on the cargo compartment 3 through a connecting piece. On the one hand, it can play a role of stable support, and on the other hand, the funnel shape can facilitate the discharge of materials and avoid the problem of material blocking.

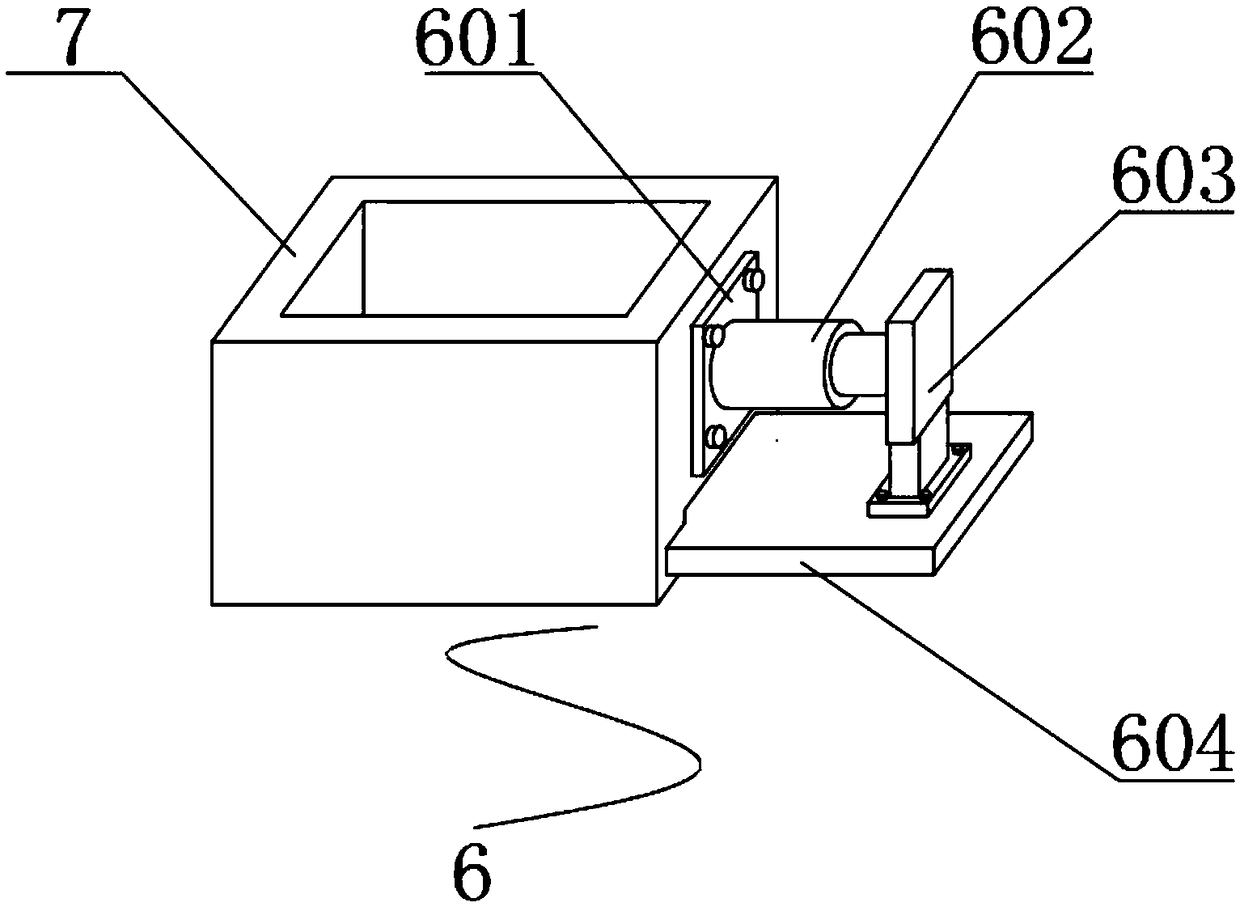

[0021] A transmission mechanism 8 is installed at the inner bottom of the cargo compartment 3 and is located at the midline position. The transmission mechanism 8 includes a side p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com