Coking coal quality classification method and coal blending and coking method with participation of coking coal

A coking coal and coal blending technology, which is applied in the coking oven and petroleum industry, etc., can solve the problems of not being able to work well and coking coal not being effective, and achieve the effect of stable improvement of coke quality and optimal blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

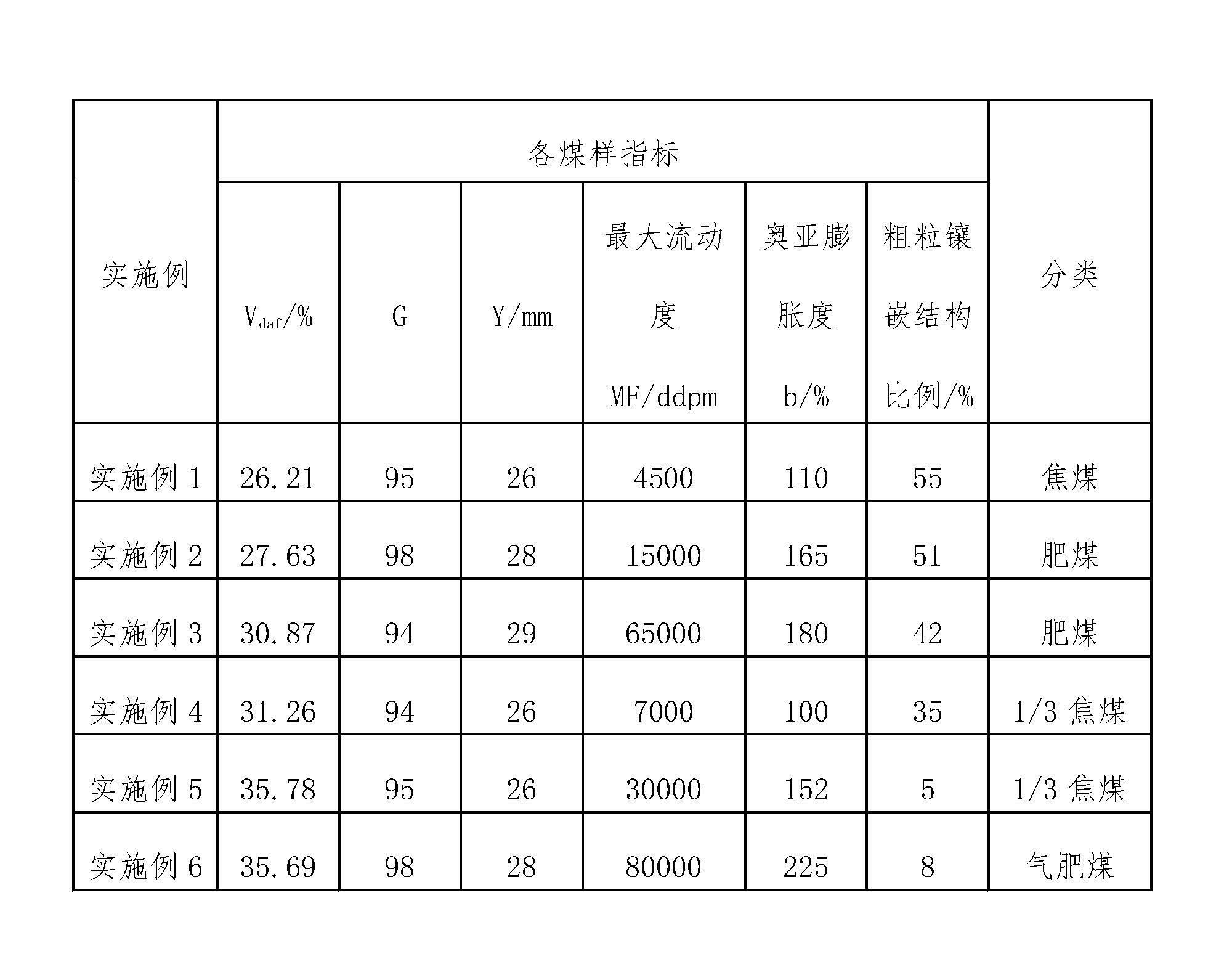

[0029] The present invention will be described in further detail below in combination with specific embodiments.

[0030] The coal quality classification method of the coking coal of the present invention is: for dry ash-free base volatile matter > 10.0-37.0%, coking index G value > 85, colloidal layer maximum thickness Y value > 25.0mm:

[0031] The first step: Determination of its dry ash-free base volatile V daf , Determination of its Kiel's fluidity to determine the maximum fluidity MF, the determination of the Aurora swelling degree b:

[0032] The second step is to classify according to the results of the first step:

[0033] Dry Ash Free Base Volatile V daf >10.0-28%, the maximum fluidity MF<10000ddpm and the expansion degree b<150%, classified as coking coal;

[0034] Dry Ash Free Base Volatile V daf >10.0-28%, the maximum fluidity MF ≥ 10000ddpm or the expansion degree b ≥ 150%, classified as fat coal;

[0035] Dry Ash Free Base Volatile V daf >28-32%, the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com