Resource utilization method of oil and gas field well drilling abandoned oil-base mud

An oil-based mud, oil and gas field technology, applied in earth-moving drilling, flushing wellbore, wellbore/well components, etc., can solve the target requirements, human health, life and production activities that cannot be treated and recycled , soil, water, farmland and air pollution, etc., to achieve the effect of saving pre-drilling project investment, eliminating environmental risks, and solving hidden dangers of pollution

Active Publication Date: 2015-03-25

PUYANG TIANDIREN ENVIRONMENTAL PROTECTION TECH CO LTD

View PDF6 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the wide distribution of oil and gas field drilling wells, if these oil-based muds are not properly treated for a long time, they will cause very serious pollution to the surrounding soil, water sources, farmland and air, and bring serious harm to human health, life and production activities. great harm

[0004] At present, most oil and gas fields have ado

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

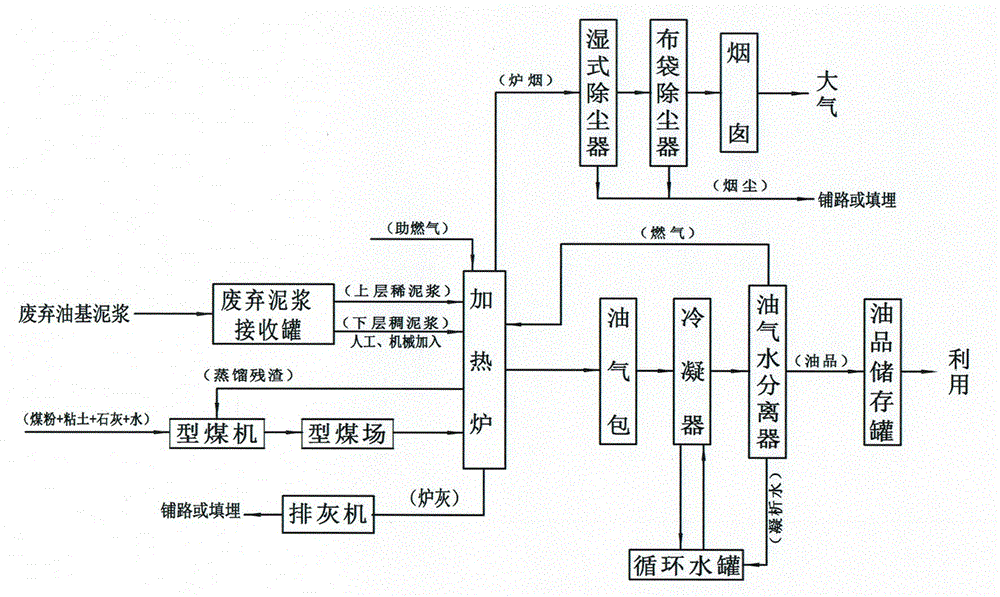

The invention discloses a resource utilization method of oil and gas field well drilling abandoned oil-base mud. The method includes the steps that firstly, the generated abandoned oil-base mud is collected into a receiving tank for sedimentation, fluid mud is generated at the upper portion after sedimentation is carried out, and solid mud is generated at the lower portion after sedimentation is carried out; the fluid mud and the solid mud are poured into a barrel of a heating furnace to be heated for splitting evaporation, oil-gas-water contents generated through splitting evaporation are sequentially fed into an oil-gas bag and a condenser for cooling, and then enter an oil-gas-water three-phase separator for separation, generated oil obtained after separation enters an oil tank from an outlet to be used, water enters the condenser to be used, and combustible gas is fed into the heating furnace to be used as fuel; residues generated after distillation are discharged out to be used as coal briquette raw materials; generated smoke is discharged after being processed to reach the standard; generated slag is discharged out to be used for road paving or backfilling. By means of the resource utilization method, oil in the abandoned well drilling oil-base mud is sufficiently recycled, and harmless and recycling comprehensive utilization of resources is achieved.

Description

technical field [0001] The invention belongs to the technical field of harmless treatment and resource comprehensive utilization of waste drilling oil-based mud in oil and gas fields, and in particular relates to a method for resource utilization of oil-gas field waste drilling oil-base mud. Background technique [0002] With the continuous development of the petroleum industry, the exploration and development of deep wells and ultra-deep wells are increasing. Oil-based mud has excellent performance and is widely used in such drilling projects. At the same time, water-sensitive formations, salt-gypsum formations and other special In formation drilling work, oil-based mud is also widely used. However, during the application of oil-based mud, a large amount of waste oil-based mud and oily drill cuttings are produced, which will cause great damage to the local environment if not treated effectively. At present, the oil-based mud commonly used in my country is mainly diesel-bas...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21B21/00

CPCE21B21/00E21B21/06E21B21/063

Inventor 胡广杰赵军胜郭学峰

Owner PUYANG TIANDIREN ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com