Mining belt conveyor coal amount detection method based on binocular stereo vision depth perception

A technology of binocular stereo vision and belt conveyor, which is applied in measuring devices, optical devices, computer parts, etc., to achieve the effect of improving calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

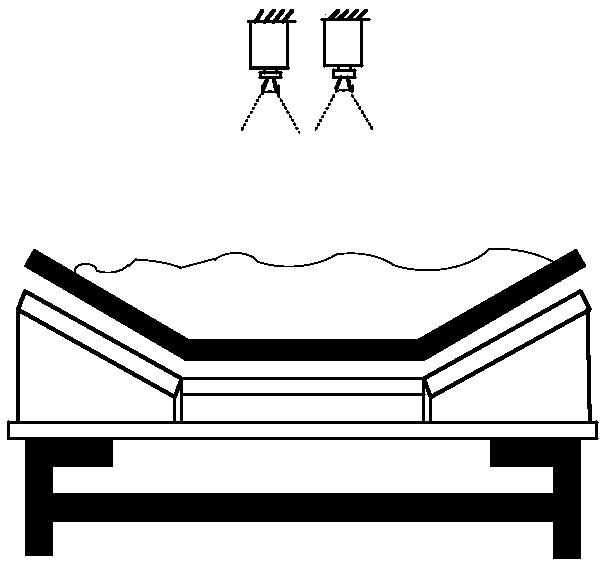

[0062] figure 1 It is a schematic diagram of a coal quantity detection system based on binocular vision. Install a speed sensor on the belt conveyor to collect the speed signal of the conveying belt in real time and transmit it to the host computer. Install two parallel cameras above the conveying belt to collect and transmit the image of the conveying coal in real time. to the host computer for image analysis and processing,

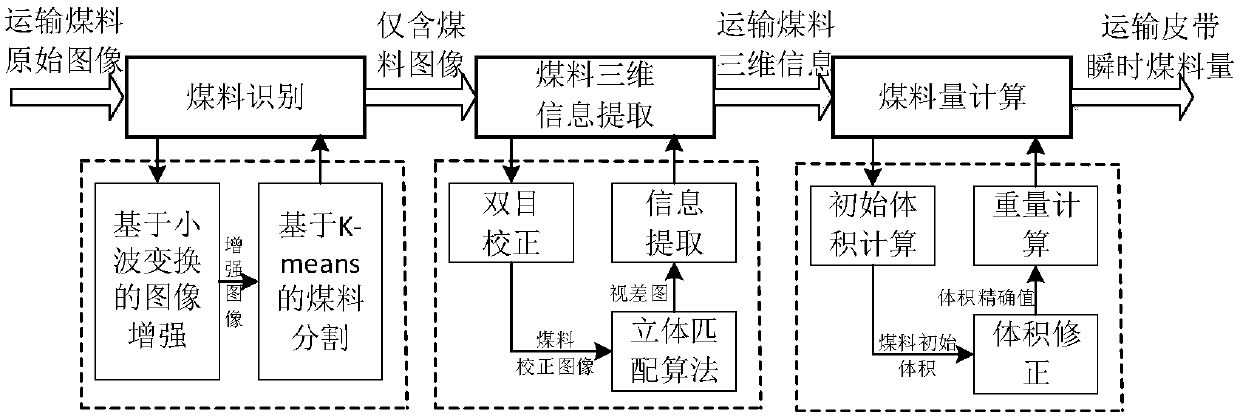

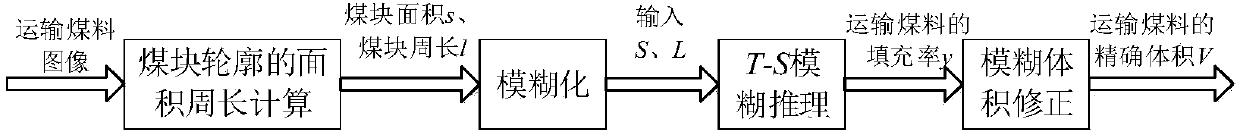

[0063] The present invention proposes a mine belt conveyor coal material detection method based on binocular stereo vision depth perception, comprising the following steps:

[0064] Step 1, identify the transported coal on the belt from the collected images containing transported coal, including: image enhancement of transported coal based on multi-resolution wavelet transform algorithm and transported coal im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com