Coal blending and coking method with participation of 1/3 coking coal having volatile of 28-32%

A coking coal and coal blending technology, applied in the field of coking coal blending, can solve the problems of unreasonable blending of coking coal and affecting the quality of coke, and achieve the effect of saving high-quality coking coal resources and optimizing blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in combination with specific embodiments.

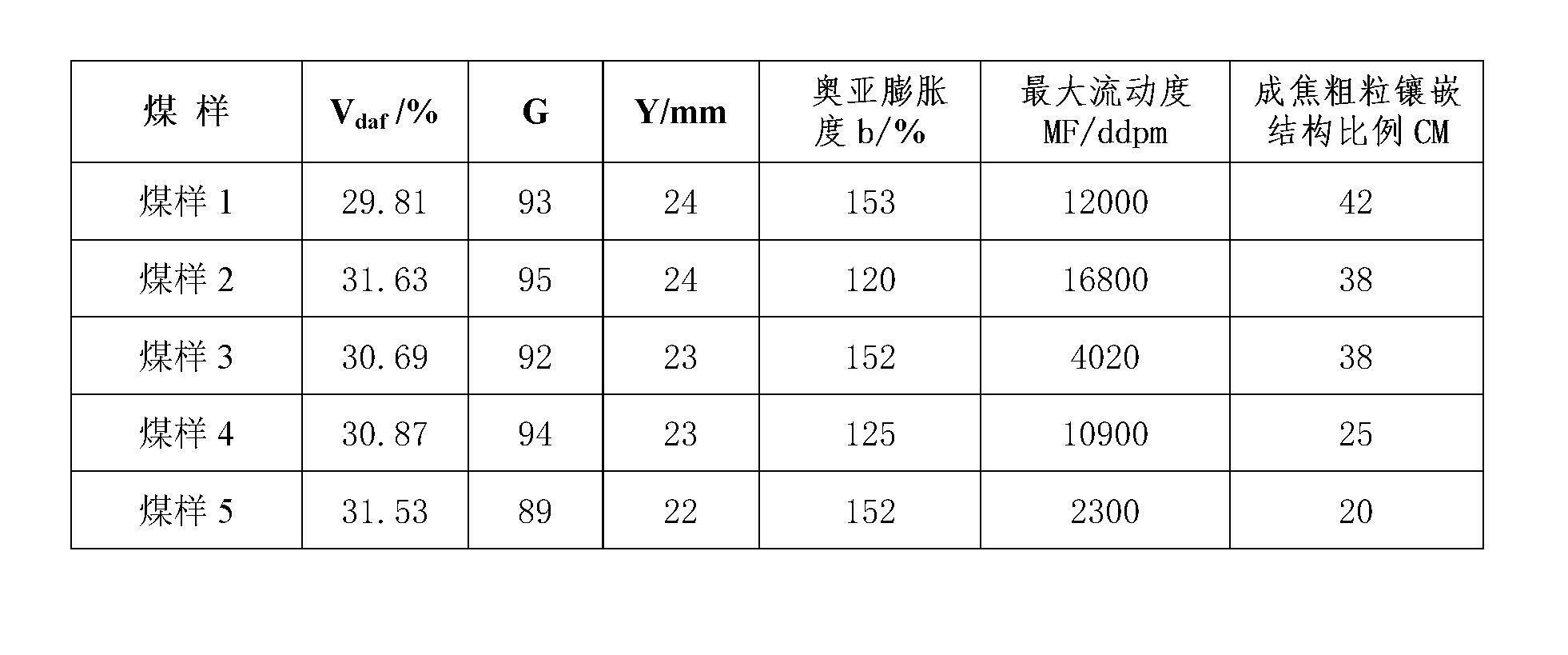

[0018] The coking coal of the present invention is 1 / 3 coking coal with dry ash-free volatile matter > 28.0-32.0%, cohesive index G value ≥ 85, and colloidal layer maximum thickness Y value ≥ 20.0mm. Its coking coal blending method is as follows:

[0019] If the Aoya expansion degree b≥150% and the maximum fluidity MF≥10000ddpm, it can be used as fat coal;

[0020] If the maximum fluidity MF<10000ddpm or the Aoya expansion degree b<150%, the coke-forming coarse-grain mosaic structure ratio CM of a single coal is ≥35%, and it is used as high-quality 1 / 3 coking coal, and the dosage is 15-30%;

[0021] If the maximum fluidity MF<10000ddpm or the expansion degree b<150%, and the coke-forming coarse-grain mosaic structure ratio CM of a single coal is less than 35%, it is used as 1 / 3 coking coal of general coal quality, and the amount is not higher than 15%. ;

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| cohesion index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com