Preparation method of high strength-hyper reactivity iron containing coke

A high-reactivity, high-strength technology, applied in the field of iron and steel metallurgy, can solve the problems of affecting the forward running of the blast furnace, increasing the coke ratio of the blast furnace, and the complexity of the whole process, and achieve the effect of protecting the coke oven, reducing the fuel ratio of the blast furnace, and simplifying the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

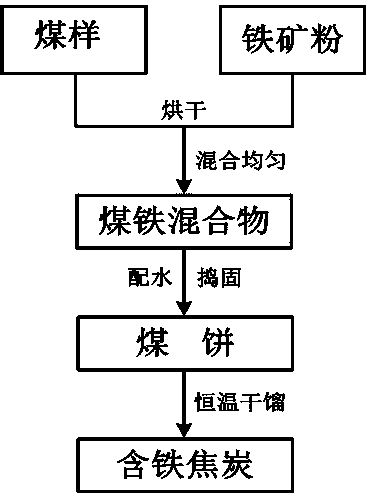

[0032] Example 1: see figure 1 , a method for preparing high-strength-high-reactivity iron-containing coke, comprising the steps of:

[0033] 1) Select the main coking coal and 1 / 3 coking coal as coal samples, pre-screen them respectively, and crush the sieved material in the jaw crusher (to prevent repeated crushing of coal samples), and re-screen the crushed coal samples After sieving, the mass percentage of coal sample particles with a particle size of 0.5~1mm in the coal sample accounts for 90% of the coal sample.

[0034] 2) Take iron ore powder with a particle size of less than 74 μm as a catalyst, then dry the iron ore powder and the coal sample that has passed step 1) in an oven at 110°C for 1.5 hours, and then use a small mixer to mix the coal sample Mix evenly with iron ore powder to obtain a mixture; add water to the mixture, put it into the coking reaction tank and tamp and seal it to obtain briquettes, wherein the quality of the added water is 10% of the mixtur...

Embodiment 7

[0043] Embodiment 7: see figure 1 , a method for preparing high-strength-high-reactivity iron-containing coke, comprising the steps of:

[0044] 1) Select the main coking coal, 1 / 3 coking coal and lean coal as coal samples, pre-screen them respectively, and crush the oversize in the jaw crusher (to prevent repeated crushing of coal samples), and the crushed coal The sample is screened again. After screening, the mass percentage of the coal sample with a particle size of 2~3mm in the coal sample accounts for 90% of the coal sample, and the content of main coking coal, 1 / 3 coking coal and lean coal respectively account for 90% of the total mass of the mixture. 59.5%, 25.5%, and 10%.

[0045] 2) Take iron ore powder with a particle size of less than 74 μm as a catalyst, then dry the iron ore powder and the coal sample that has passed step 1) in an oven at 110°C for 1.5 hours, and then use a small mixer to mix the coal sample Mix evenly with iron ore powder to obtain a mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com