Method for synthesizing ultrafine calcium carbonate by utilizing carbide slag

A technology of ultra-fine calcium carbonate and carbide slag, which is applied to the removal of calcium carbonate/strontium/barium and solid waste, and can solve the problems of interface defects between base materials and fillers, insufficient utilization, and low calcium carbonate yield, and achieve Increase affinity and compatibility, highlight social and economic benefits, and improve resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

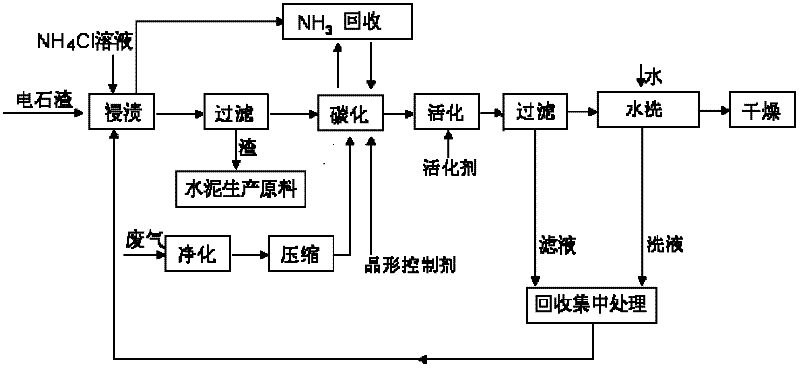

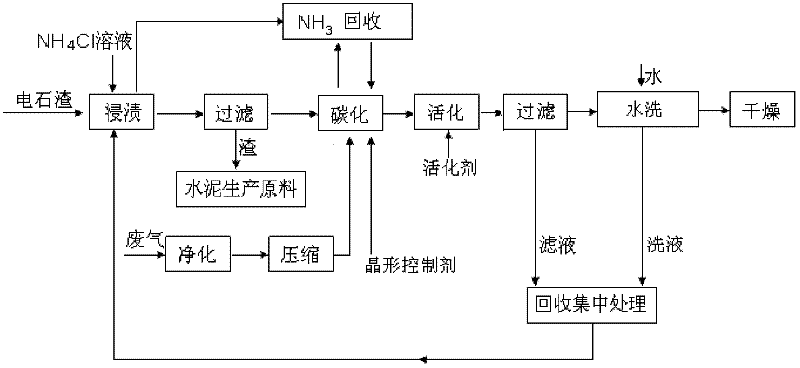

Image

Examples

Embodiment 1

[0025] Mix calcium carbide slag with a water content of 35% and water evenly in a mass ratio of 1:10, so that the calcium carbide slag is fully dissolved into a suspension, and ammonium chloride is added to the suspension of calcium carbide slag to fully react to control the solution. The pH value is greater than or equal to 7, the mass ratio of calcium carbide slag and ammonium chloride is 1: 0.78, after removing the residue, add crystal form control agent N-methylpyrrolidone and sodium dodecylbenzenesulfonate (mass ratio is 1: 1 ), the addition of the control crystal form control agent is that the carbonization reaction generates 1% of the weight of calcium carbonate, and then passes through the purification back containing CO 2 Gas (CO 2 The volume percentage is 30%) of cement factory kiln exhaust gas or power plant flue gas for carbonization, and the temperature of the carbonization reaction is controlled at 10-25 °C until the pH value of the solution is less than or equal...

Embodiment 2

[0027]Mix calcium carbide slag with a water content of 35% and water evenly in a mass ratio of 1:10, so that the calcium carbide slag is fully dissolved into a suspension, and ammonium chloride is added to the suspension of calcium carbide slag to fully react to control the solution. The pH value is greater than or equal to 7, the mass ratio of calcium carbide slag and ammonium chloride is 1: 0.78, after removing the residue, add crystal form control agent N-methylpyrrolidone and sodium dodecylbenzenesulfonate (mass ratio is 1: 1 ), the addition of the control crystal form control agent is that the carbonization reaction generates 1% of the weight of calcium carbonate, and then passes through the purification back containing CO 2 Gas (CO 2 The volume percentage is 30%) of cement factory kiln exhaust gas or power plant flue gas for carbonization, and the temperature of the reaction is controlled at 10-25°C until the pH value of the solution is less than or equal to 7, and the c...

Embodiment 3

[0029] Mix calcium carbide slag with a water content of 35% and water evenly in a mass ratio of 1:9, so that the calcium carbide slag is fully dissolved into a suspension, and ammonium chloride is added to the suspension of calcium carbide slag to fully react to control the solution. The pH value is greater than or equal to 7, the mass ratio of calcium carbide slag and ammonium chloride is 1: 0.78, after removing the residue, add crystal form control agent potassium pyrophosphate and sodium dodecylbenzenesulfonate (mass ratio is 2: 1), Control the adding amount of crystal form control agent to be 1% of the weight of calcium carbonate generated by carbonization reaction, and then pass into the purified CO 2 Gas (CO 2 The volume percentage is 30%) of cement factory kiln exhaust gas or power plant flue gas for carbonization, and the temperature of the reaction is controlled at 10-25°C until the pH value of the solution is less than or equal to 7, and the carbonized superfine Cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com