Method for producing propene using silicoaluminophosphate molecular sieve catalytic cracking

A technology for catalytic cracking and silicoaluminophosphate, applied in the fields of catalysis and chemical engineering, can solve problems such as low temperature, and achieve the effects of improved product selectivity, high cracking activity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

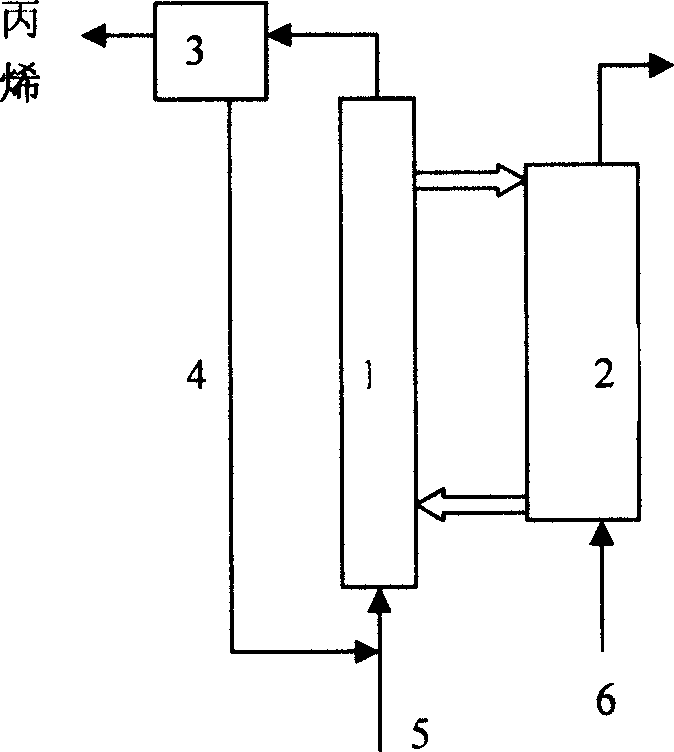

Image

Examples

Embodiment 1

[0023] The used SAPO-34 molecular sieve, the synthetic raw material is Al 2 o 3 :P 2 o 5 : SiO 2 :TEA=1:0.76:0.81:2.4, product Al 2 o 3 / SiO 2 The molar ratio is close to 1. Molecular sieves are calcined at 600°C for 4 hours, then bonded with silica sol, and the weight content of SAPO-34 is 90%. After crushing, take 60-120 meshes for use. Take by weighing the catalyzer that 20mg above-mentioned method obtains, be placed in the microreactor of quartz tube fixed bed and under N 2 After medium activation, the catalytic cracking dry gas with an ethylene weight content of 23% enters in a pulsed manner with a carrier gas with a flow rate of 10ml / min, and the equivalent weight space velocity is about 36h -1 (Based on ethylene), the reaction temperature is 350°C, the pressure is 0.3MPa, the tail gas is detected by gas chromatography, alumina packed column, and hydrogen flame detector. The conversion of ethylene is about 15%, and the selectivity of propylene is 36%. The produc...

Embodiment 2

[0026] The molar ratio of synthetic raw materials for SAPO-34 molecular sieve is Al 2 o 3 :P 2 o 5 : SiO 2 :LaO:TEA=1:1:0.16:0.015:2.4. Prepare the catalyst with 5% weight content of SAPO-34 as in Example 1. Take by weighing the catalyzer that 300mg above-mentioned method obtains, place in quartz tube fixed-bed micro-reactor and under N 2 After activation in the medium, with the raw material of embodiment 1 with the about 0.12h of reduced weight space velocity -1 (Based on ethylene) is fed continuously, the reaction temperature is 450°C, the pressure is 0.11MPa, the tail gas is detected by gas chromatography, alumina packed column, and hydrogen flame detector. The conversion of ethylene is about 79%, and the selectivity of propylene is 42%. The product distribution is shown in Table 1.

[0027] Conversion rates

Embodiment 3

[0029] SAPO-34 molecular sieve, its synthesis raw material molar ratio is Al 2 o 3 :P 2 o 5 : SiO 2 :TEA=1:1:0.6:2.4, catalyst particles were prepared according to Example 1, and the weight content of SAPO-34 was 90%. Take by weighing 20mg prepared catalyst, place in quartz tube fixed-bed microreactor, under the N of 15ml / min 2 The temperature was raised to 500°C for 1 hr and then lowered to 450°C. Switch the N2 flow to a mixture of C4 components, the flow rate is 40ml / min, and the equivalent weight space velocity is close to 300h -1 , the pressure is normal pressure, and the intercepted tail gas is analyzed with embodiment 1.

[0030] The raw material is a C4 mixture, 2-butene accounts for 96%, of which cis-butene is 54%, trans-butene is 42%, and the rest is butane.

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com