A neoprene-based non-magnetic wave-absorbing patch material and preparation method thereof

A technology of chloroprene rubber and wave-absorbing patch, which is applied in the field of civil wave-absorbing materials, can solve the problems of specific gravity restriction, high density of magnetic absorbent, easy to fall off, etc., and achieve poor mechanical properties, high tensile strength, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The neoprene composite non-magnetic wave-absorbing patch material provided in this embodiment is made of neoprene, absorbent, zinc oxide, vulcanizing agent and accelerator.

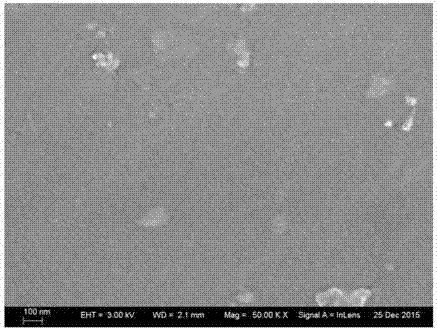

[0036] The neoprene CR232 is used as the base material of the product in this embodiment.

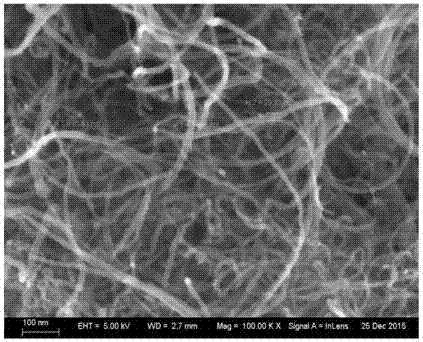

[0037] The absorber adopts non-magnetic material carbon nanotube.

[0038] The vulcanizing agent adopts zinc oxide and light magnesium oxide.

[0039] The accelerator adopts NA22 accelerator.

[0040] The chloroprene rubber composite non-magnetic wave-absorbing patch material provided in Example 1 above can be made by the method provided in the following examples.

Embodiment 2

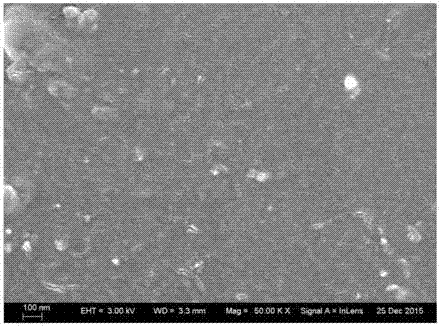

[0042] Accurately weigh neoprene, zinc oxide, magnesium oxide, carbon nanotubes, accelerator NA22 according to the mass ratio of 100:5:4:5:1. Neoprene, zinc oxide, magnesium oxide and carbon nanotubes were mixed on a double-roller open mill, bagged in triangles and pillows 20 times, and thinned 20 times. Mix for 30 minutes, add accelerator NA22, mix for 8 minutes and then release the tablet. Use a flat vulcanizer to vulcanize the mixed raw rubber at a temperature of 145°C and a pressure of 10MPa. The vulcanization time for a patch with a thickness of 3mm is 40min. A sheet-shaped absorbing material with a specification of 300mmX300mm is produced.

[0043] The microwave absorption performance of the patch is measured by the bow reflection method, and the test frequency is 2-18GHz. Before the test starts, the vector network analyzer should be turned on and warmed up for 30 minutes. Each patch needs to measure 3 frequency bands, namely 2-6GHz, 4-8GHz, 8-18GHz. Comprehensive 3-...

Embodiment 3

[0045] Accurately weigh neoprene, zinc oxide, magnesium oxide, carbon nanotubes, accelerator NA22 according to the mass ratio of 100:4:4:5:1. Neoprene, zinc oxide, magnesium oxide and carbon nanotubes were mixed on a double-roller open mill, bagged in triangles and pillows 20 times, and thinned 20 times. Mix for 30 minutes, add accelerator NA22, mix for 8 minutes and then release the tablet. Use a flat vulcanizer to vulcanize the mixed raw rubber at a temperature of 145°C and a pressure of 10MPa. The vulcanization time for a patch with a thickness of 3mm is 40min. A sheet-shaped absorbing material with a specification of 300mmX300mm is produced.

[0046] The microwave absorption performance of the patch is measured by the bow reflection method, and the test frequency is 2-18GHz. Before the test starts, the vector network analyzer should be turned on and warmed up for 30 minutes. Each patch needs to measure 3 frequency bands, namely 2-6GHz, 4-8GHz, 8-18GHz. Comprehensive 3-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com