Concrete mixing plant system and operation method thereof

An operation method and concrete technology, applied in mixing plants, chemical instruments and methods, mixing operation control, etc., can solve the problem of different distances, low solidification rate of ready-mixed concrete, single ready-mixed concrete formula is difficult to meet different construction units at the same time, etc. problem, to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The application will be described in further detail below in conjunction with the accompanying drawings.

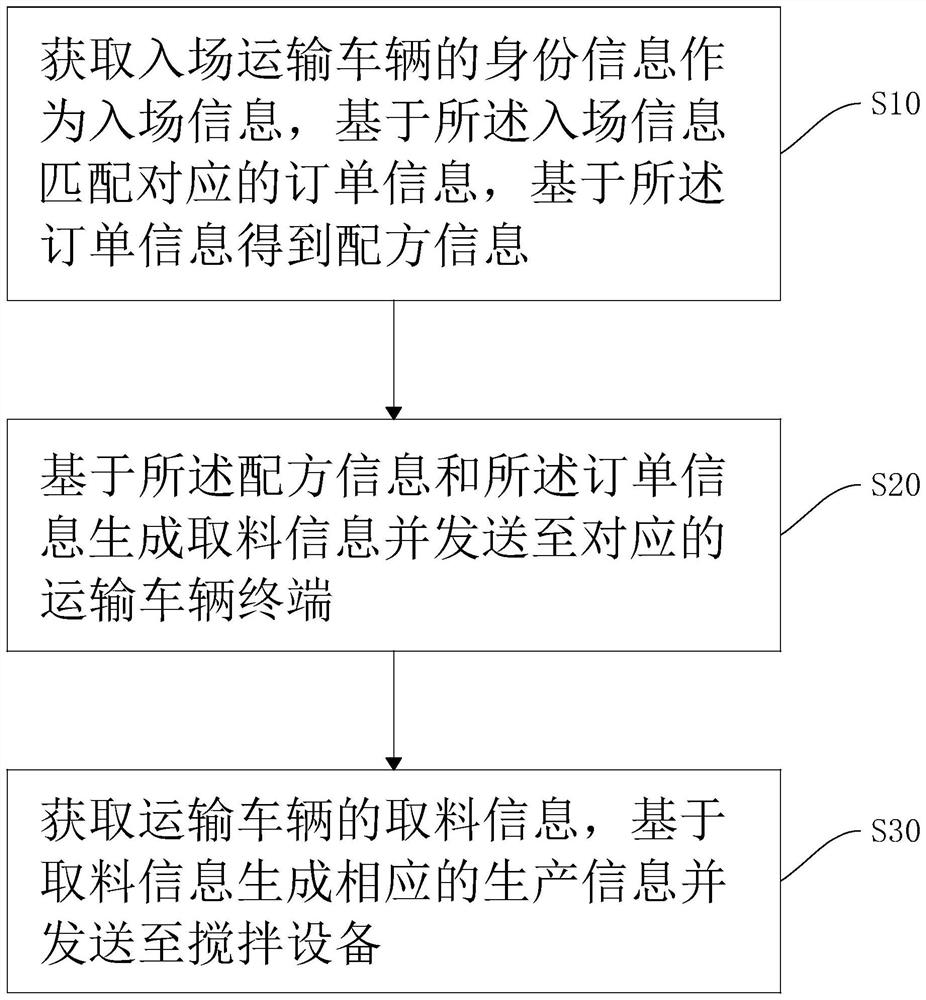

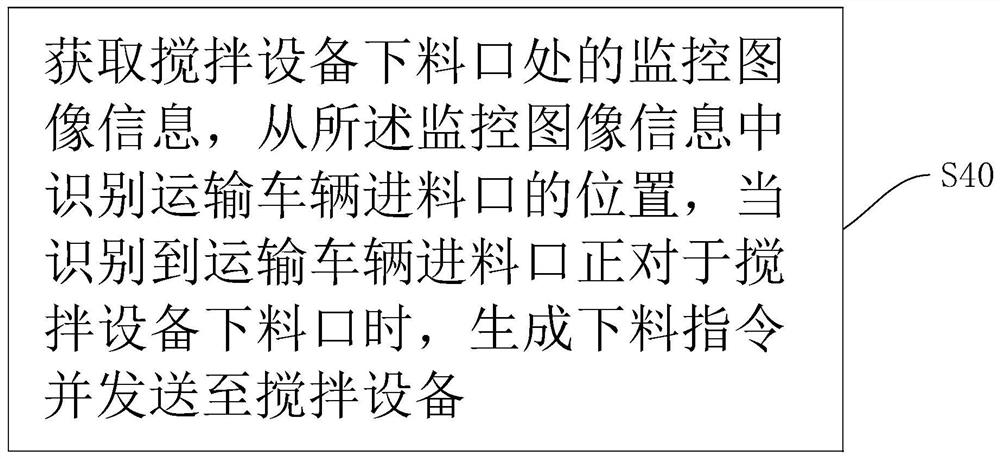

[0055] In one embodiment, as figure 1 As shown, the application discloses a method for operating a concrete mixing plant, which specifically includes the following steps:

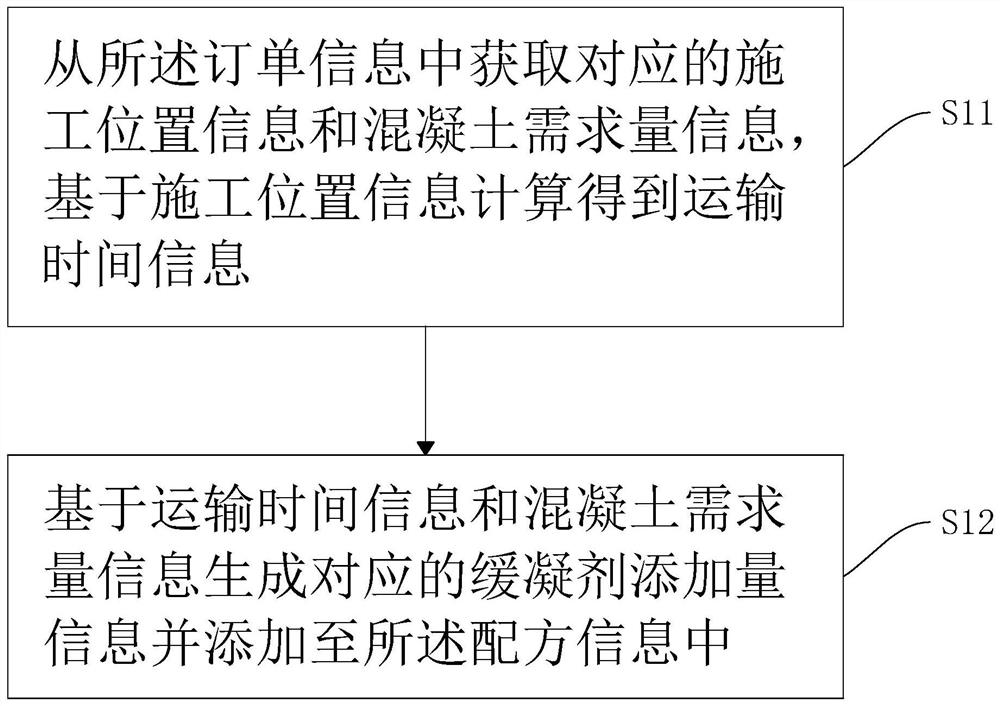

[0056] S10: Obtain the identity information of the transport vehicle entering the site as the entry information, match the corresponding order information based on the entry information, and obtain formula information based on the order information.

[0057] In this embodiment, the identity information refers to the information used to identify the transport vehicle entering the site; the order information refers to the concrete purchase order made by the construction unit corresponding to the transport vehicle according to the actual construction demand.

[0058] Specifically, the identity information of the transport vehicle entering the site can be the license plate number information, or th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com