Filler for smoke desulfurization and denitrification and preparation method thereof

A technology for desulfurization, denitrification, and flue gas, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of high flue gas pollution index, insignificant desulfurization and denitrification effect, waste of industrial sulfuric acid resources, etc., so as to avoid physical harm. , excellent desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

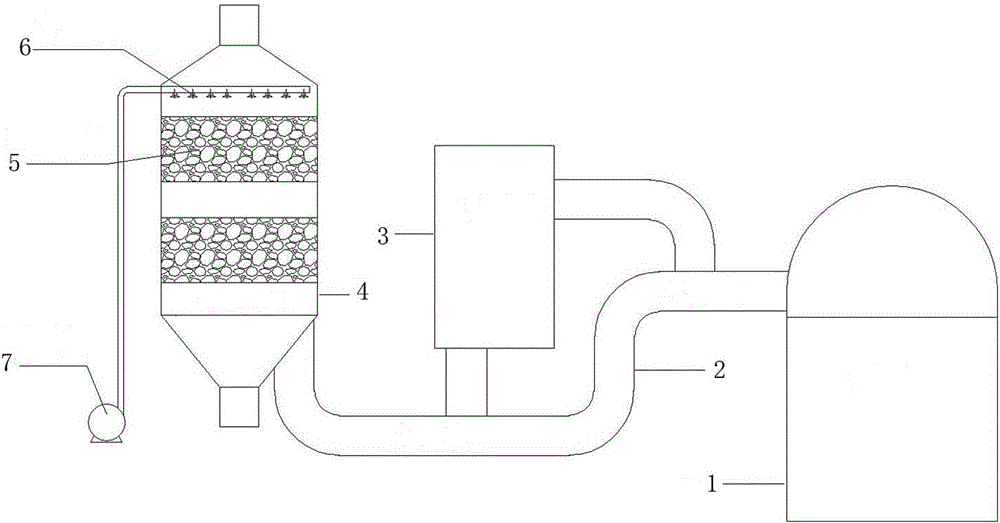

Image

Examples

Embodiment 1

[0025] 4 parts of MgO, MgCl 2 ·6H 2 O 6 parts, phosphoric acid 0.1 part, glass fiber 1 part, adhesive neoprene rubber powder 0.5 part, hydrogen peroxide 0.8 part.

[0026] The preparation method of the filler for flue gas desulfurization and denitrification comprises the following steps.

[0027] (1) Ingredients and stirring: Weigh magnesium oxide, magnesium chloride, glass fiber, rubber powder and phosphoric acid according to the proportion by weight, put them into a stirrer and stir at 2000r / min, stir for 10 min; then add hair Foaming agent, continue to stir for 2 minutes.

[0028] (2) Molding and foaming treatment: Add the mixed material stirred in step (1) into the mold, let it stand for 45 minutes for foaming, put it into a constant temperature workshop with an ambient temperature of 50°C, store it for 2 days, and increase the curing strength. Take out the finished product and set aside.

[0029] In the flue gas desulfurization and denitrification process, the packing...

Embodiment 2

[0031] 5 parts of MgO, MgCl 2 ·6H 2 O 5 parts, phosphoric acid 0.5 parts, glass fiber 0.2 parts, nitrile rubber powder 0.8 parts, hydrogen peroxide 0.5 parts.

Embodiment 3

[0033] 6 parts of MgO, MgCl 2 ·6H 2 8 parts of O, 0.4 parts of phosphoric acid, 0.8 parts of glass fiber, 1 part of polyisobutylene rubber powder, and 1 part of hydrogen peroxide.

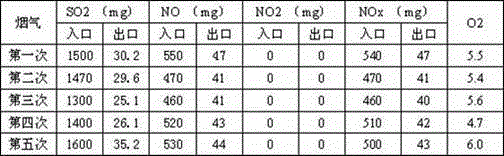

[0034] 1. Example test.

[0035] 1. Test location: Zhangwu County.

[0036] 2. Test time: September 6th.

[0037] 3. Test conditions: The packing prepared in Example 1 is used to treat the flue gas discharged from a 2-ton coal-fired steam boiler, the air volume is 10,000 air volume, and the diameter of the desulfurization and denitrification tower is Φ1200 and the height is 13 meters.

[0038] 4. Test results: See Table 1.

[0039] Table 1 The content of sulfur and nitrogen compounds before and after flue gas treatment.

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com