Composite desulfuration method for molten iron

A technology of molten iron and desulfurization agent, applied in the field of iron and steel metallurgy, can solve the problem of difference at the beginning, and achieve the effect of small temperature drop, enhanced desulfurization effect and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0033] According to the composite desulfurization method of the present invention, a rotary spray gun with a pulse stirrer is used to perform composite desulfurization treatment on molten iron by pulse stirring method and rotary spray gun injection method.

[0034] Drive the molten iron tank (bale) to the injection desulfurization station (positioning device is installed on the railway), the system starts to run, the rotary spray gun starts to input the desulfurizer according to the injection system program, and at the same time carry out positive and negative two-way pulse stirring, in order to In contrast, one of the desulfurization furnaces still uses unidirectional rotation and stirring. After 5 cans (packages) of molten iron reach the calculated injection volume, the gun is automatically lifted to stop stirring and blowing. When the desulfurizer is put in from the top of the ladle (tank), the molten iron is put into the meterable hopper.

[0035] The chemical composition ...

Embodiment 6

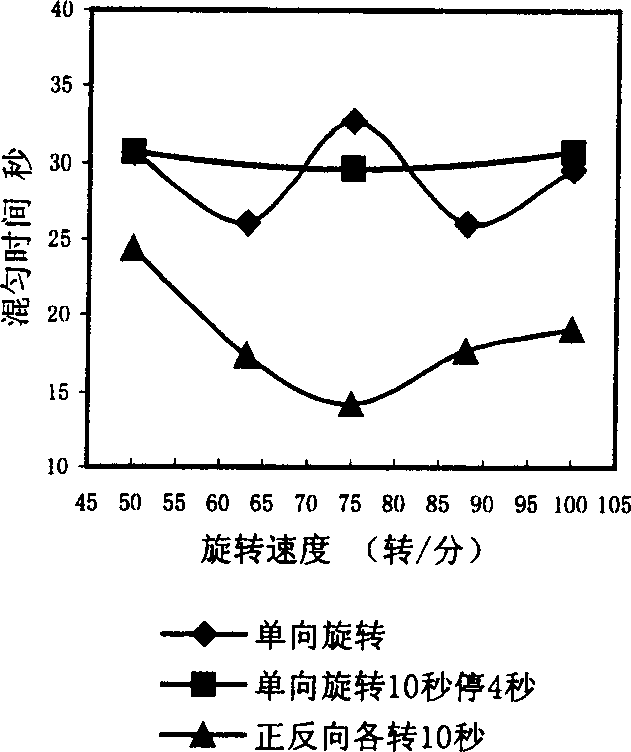

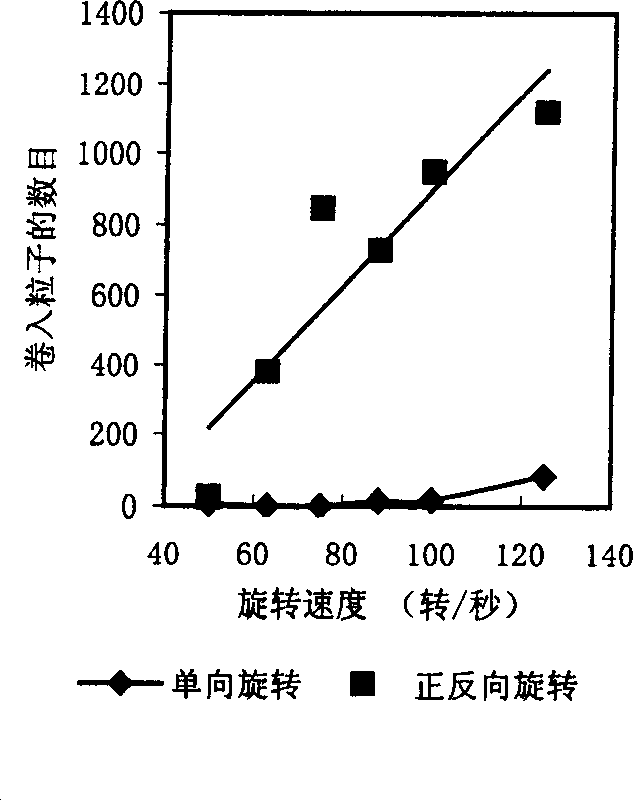

[0037] In order to verify the correctness, advancement and desulfurization effect of the composite desulfurization of the pulse type stirring method and the rotary lance injection method described in the present invention, the present invention adopts the method of physical simulation (i.e. hydraulic model experiment) to unidirectional rotary stirring and Contrastive experiments were carried out between positive and negative two-way rotation stirring and rotation-stop-rotation pulse rotation stirring.

[0038] 1. Test device and method

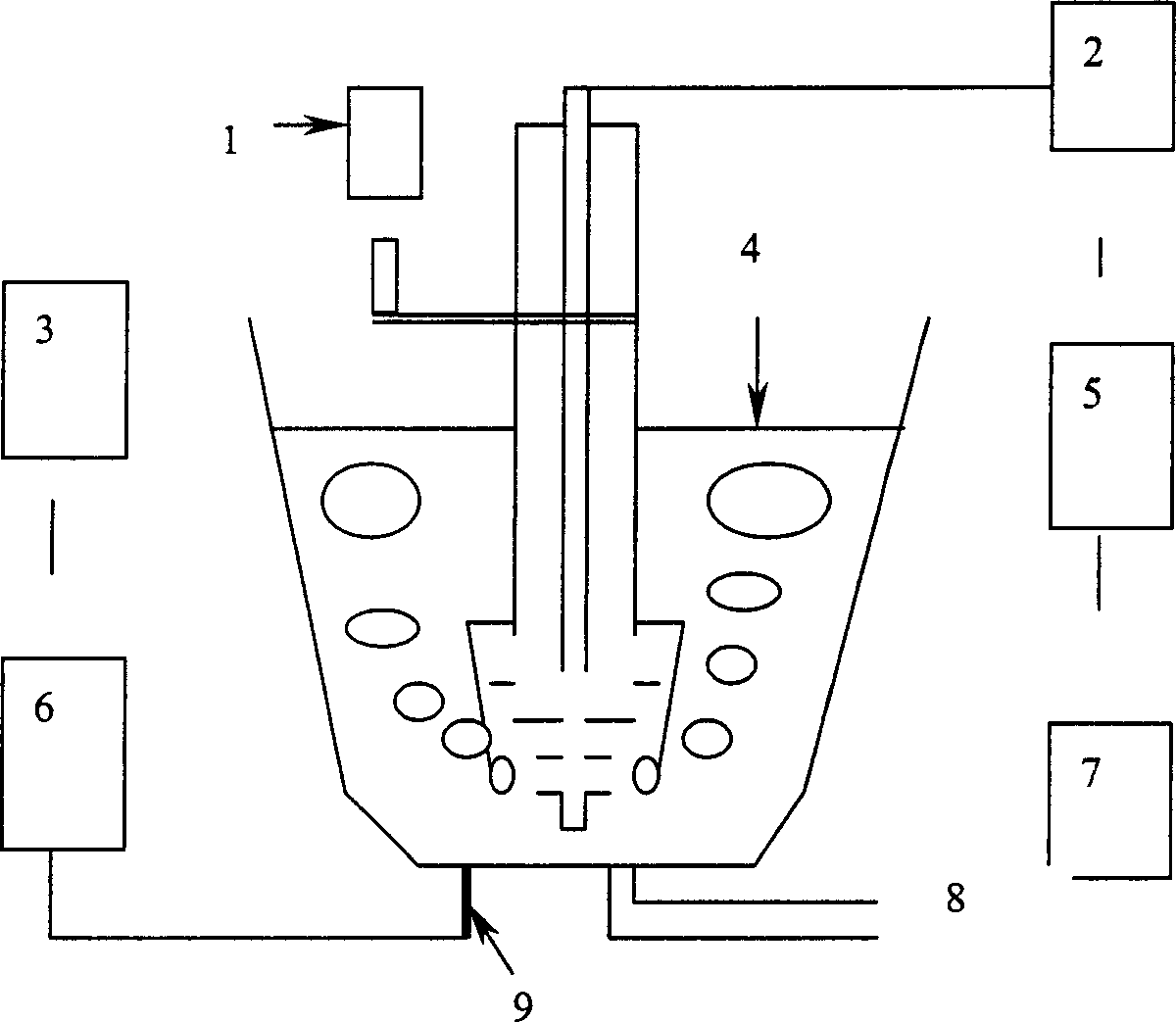

[0039] Test device such as figure 1 shown. In the figure, 1 is a variable speed motor, 2 is a flow meter, 3 is a recorder, 4 is NaCl, 5 is a pressure gauge, 6 is a conductivity meter, 7 is an air source, 8 is a drain pipe, and 9 is a conductivity electrode.

[0040] Make a model according to the ratio of the actual ladle prototype = 1:4, use water to simulate molten iron, and compressed air to simulate the carrier gas for injecting desulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com