Method for preparing narrow fraction nontoxic high-purity isohexane

A technology of isohexane and narrow fraction, which is applied in the field of preparation of nontoxic and high-purity isohexane with narrow fraction, can solve the problems of not being able to meet the environmental protection requirements of safe production of nontoxic narrow fraction solvent oil from plant extract oil, and achieve remarkable desulfurization effect, Simple production process and high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

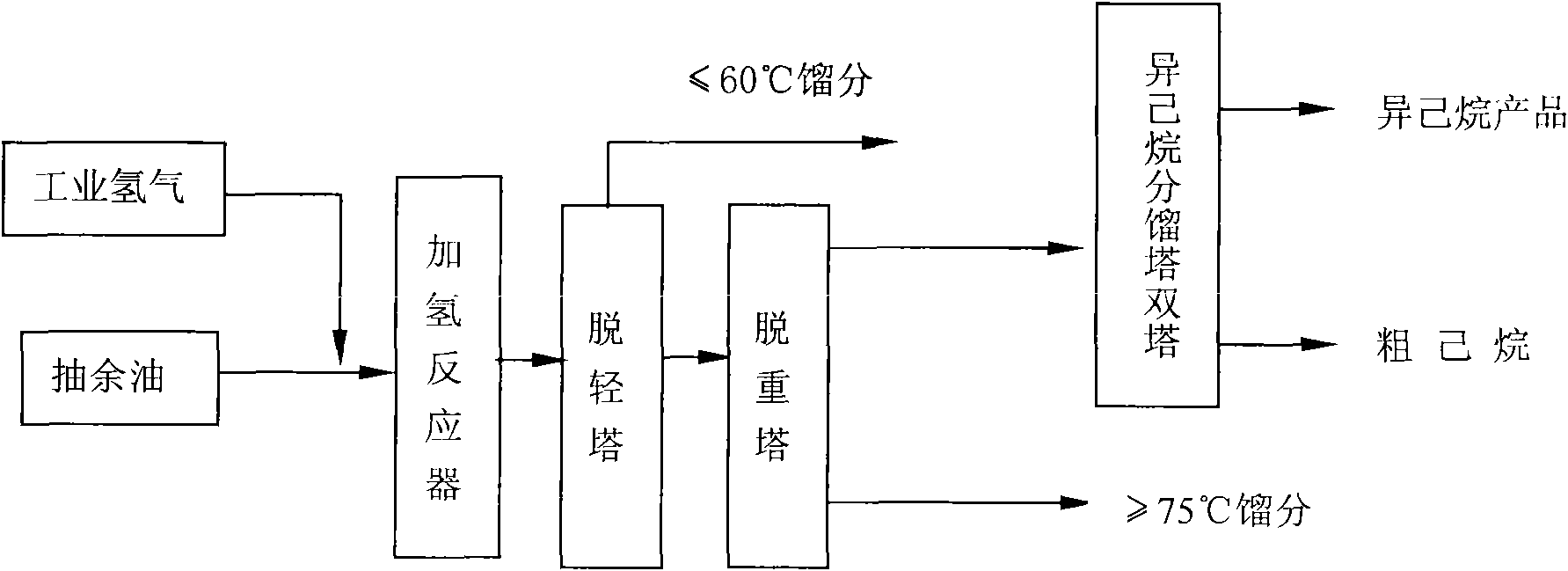

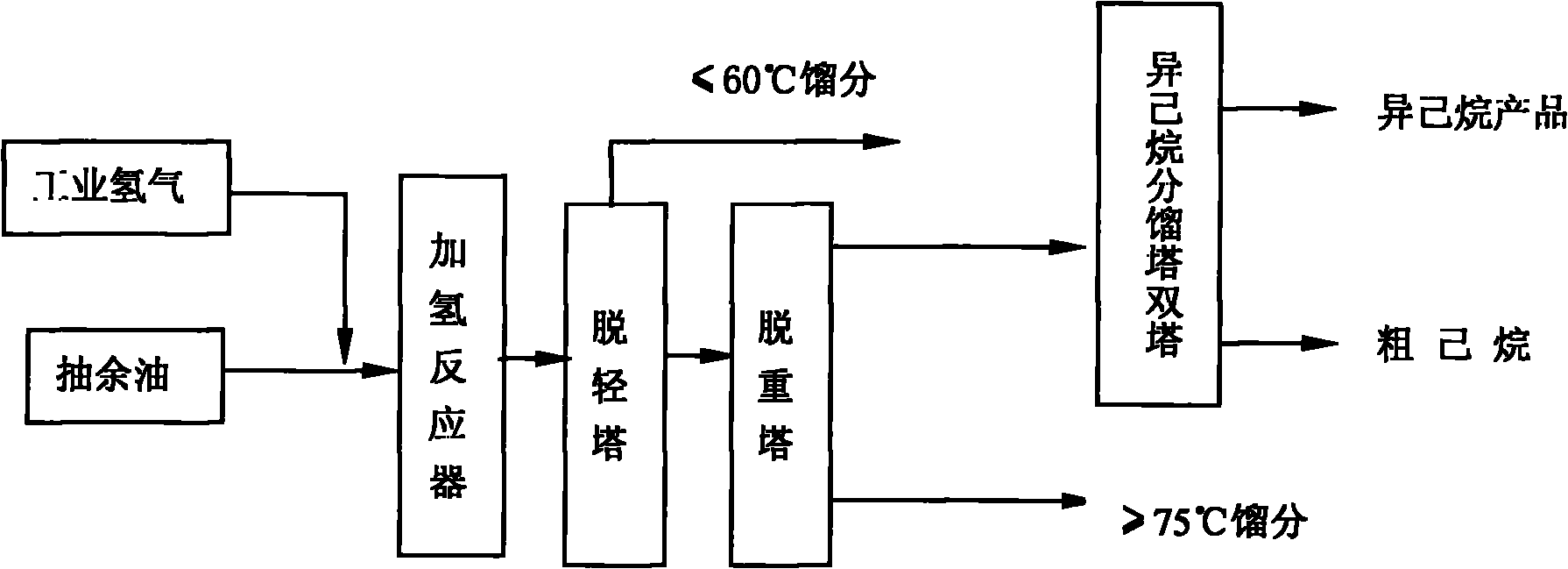

Image

Examples

Embodiment Construction

[0015] (1), choose active metal nickel as benzene series catalytic hydrogenation catalyst:

[0016] The active center of the selected catalyst is metal nickel, the shape is cylindrical (Φ5mm×5mm), the bulk density is 1-1.4 liters / kg, and the specific surface area is 95-180cm 2 / kg, strength ≥ 140N / cm, put it in a hydrogenation reactor, when the catalytic reforming raffinate enters the hydrogenation reactor together with industrial hydrogen, it will contact with the catalyst for heterogeneous reaction, and carry out hydrogenation to remove Benzene series.

[0017] (2), catalytic hydrodearomatization and sulfur:

[0018] The raw material catalytic reforming raffinate and industrial hydrogen are preheated to 160°C and simultaneously pumped into the hydrogenation reactor. , Liquid benzene space velocity 0.02 / h, reactor temperature 171°C, inlet hydrogen pressure 1.0Mpa, hydrogenation pressure 1.37Mpa under the conditions of catalytic hydrogenation reaction, dearomatization and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com