Composite desulfurization blender of double-blade molten iron

A hot metal desulfurization and agitator technology, which is applied in the field of metallurgical desulfurization equipment, can solve the problems of unsatisfactory desulfurization effect, low price, and low stirring efficiency, and achieve ideal desulfurization effect and high stirring efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

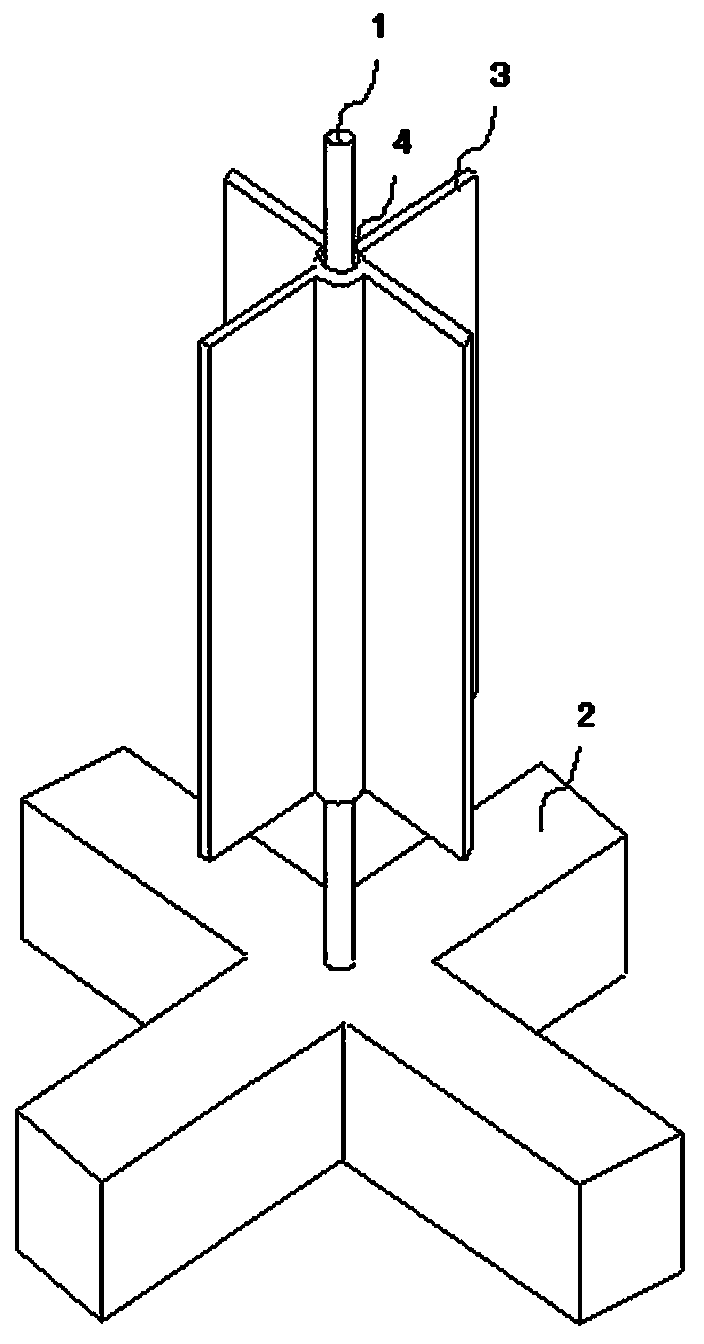

[0013] As shown in the figure, the double-bladed molten iron desulfurization compound agitator includes a central agitating shaft 1, a bottom agitating blade 2 and an upper agitating blade 3; the bottom agitating blade 2 is fixedly connected to the lower end of the central agitating shaft 1; The central sleeve 4 of the upper stirring blade 3 is slidingly socketed with the central stirring shaft 1 .

[0014] The bottom stirring blade 2 of the present invention can adopt a four-blade structure. The upper stirring blade 3 of the present invention can adopt a four-blade structure.

[0015] The present invention adopts the upper blade structure of the bottom stirring blade and the upper stirring blade, and under the combined motion of the upper stirring blade and the bottom stirring blade, a composite vortex effect will be formed in the stirring area, the stirring efficiency of the agitator is higher, and the desulfurization effect is more ideal .

[0016] The invention can obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com