Automatic wire arrangement and balance device of multi-wire cutting machine

A multi-wire cutting machine and automatic wire arranging technology, which is applied to fine working devices, working accessories, stone processing equipment, etc., can solve problems such as bad consequences, broken wires, and wire saws for cutting products with tension changes, so as to reduce broken wires The possibility of guaranteeing the cutting effect and the effect of eliminating the phenomenon of wire sawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings.

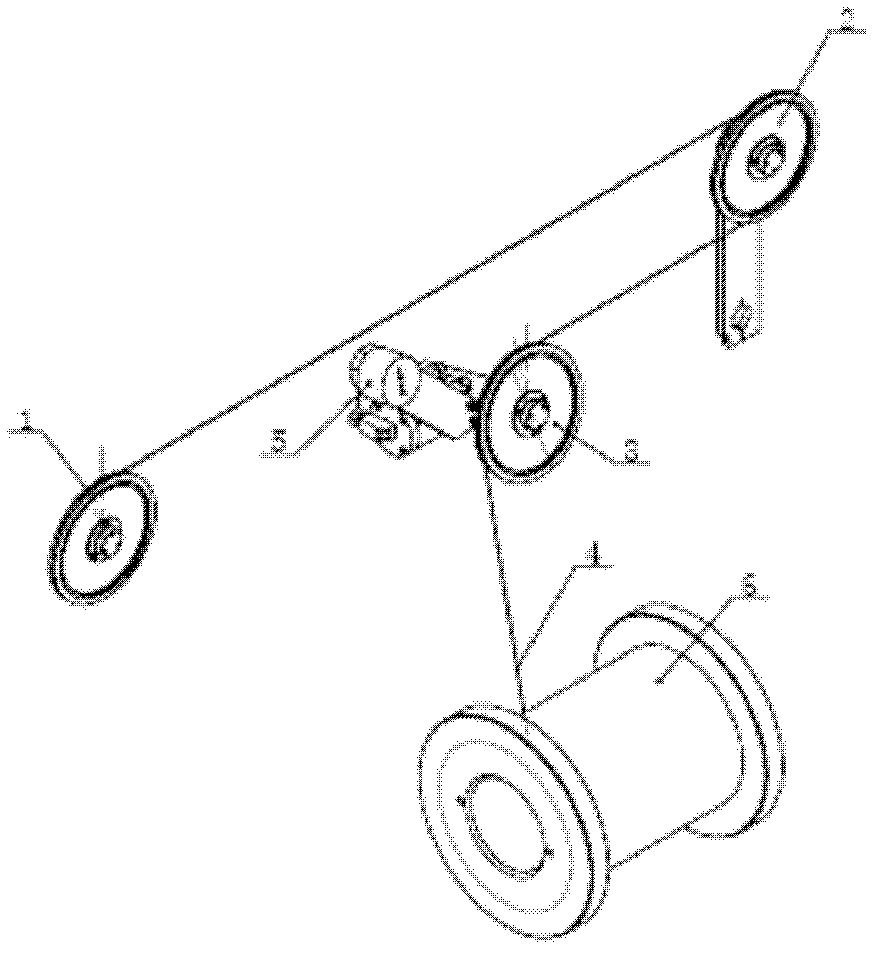

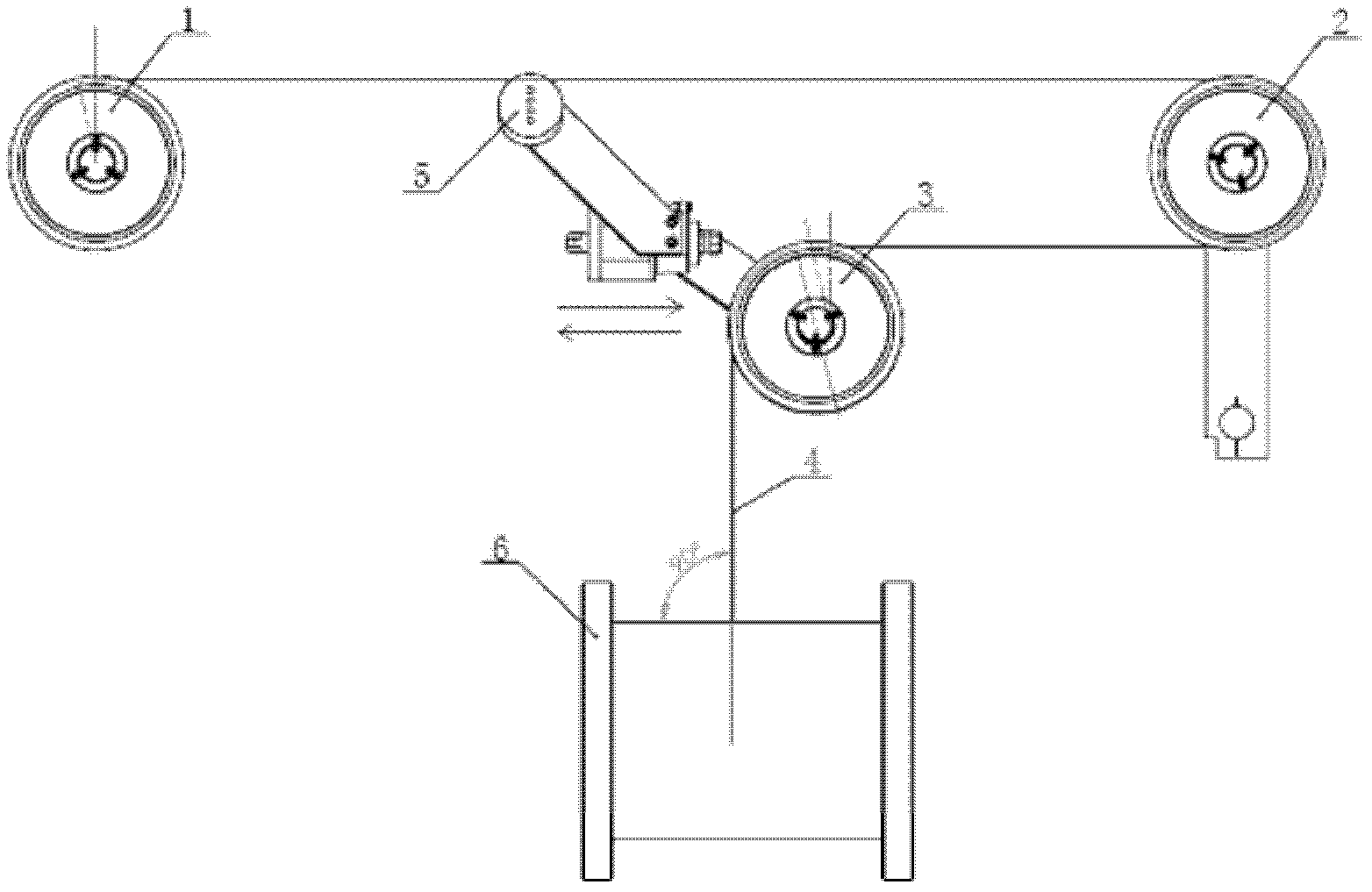

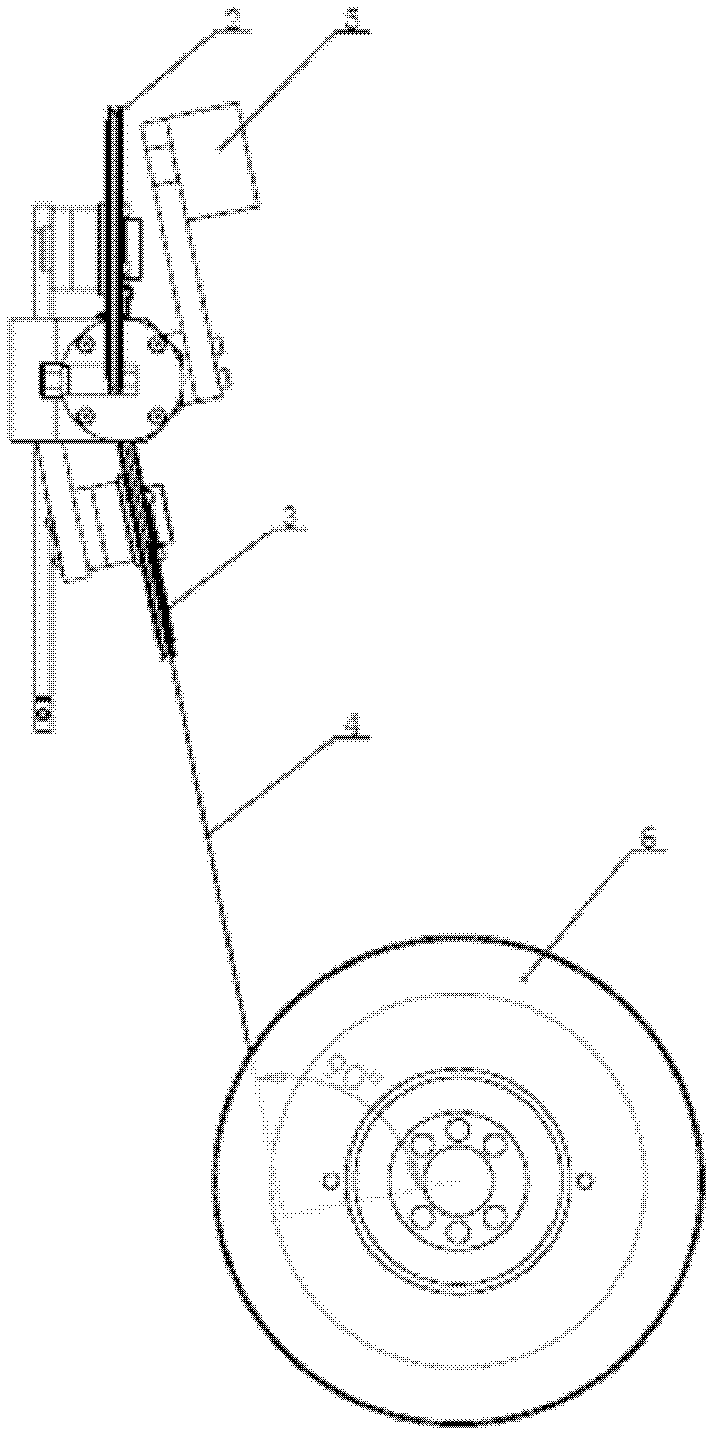

[0011] Such as Figure 1~Figure 3 Shown: The automatic wire arrangement and automatic balancing device of the multi-wire cutting machine includes a wire pulley 1, a tension control pulley 2, a swingable wire pulley 3, a cutting wire 4, a counterweight 5, and a wire pulley 6, etc.

[0012] The present invention comprises a wire pulley 1, a tension control pulley 2, a swingable wire pulley 3 and a wire pulley 6 for retracting a cutting wire 4, and the cutting wire 4 passes through the wire pulley 1, the tension control pulley 2, and the swingable wire pulley in turn. The wire pulley 3 is wound on the wire pulley 6, and the cutting wire 4 is wound on the wire pulley 6 along the tangential direction of the outer peripheral surface of the wire pulley 6;

[0013] A counterweight 5 is installed on the swingable wire pulley 3, and the counterweight 5 is used to automatically balance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com