Agricultural sugarcane juicer

A juicer and sugarcane technology, applied in the fields of application, juice extraction, food science, etc., can solve the problems of crushing and easily damaged juicer, and achieve the effect of improving quality, strengthening the effect of crushing, and improving the effect of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

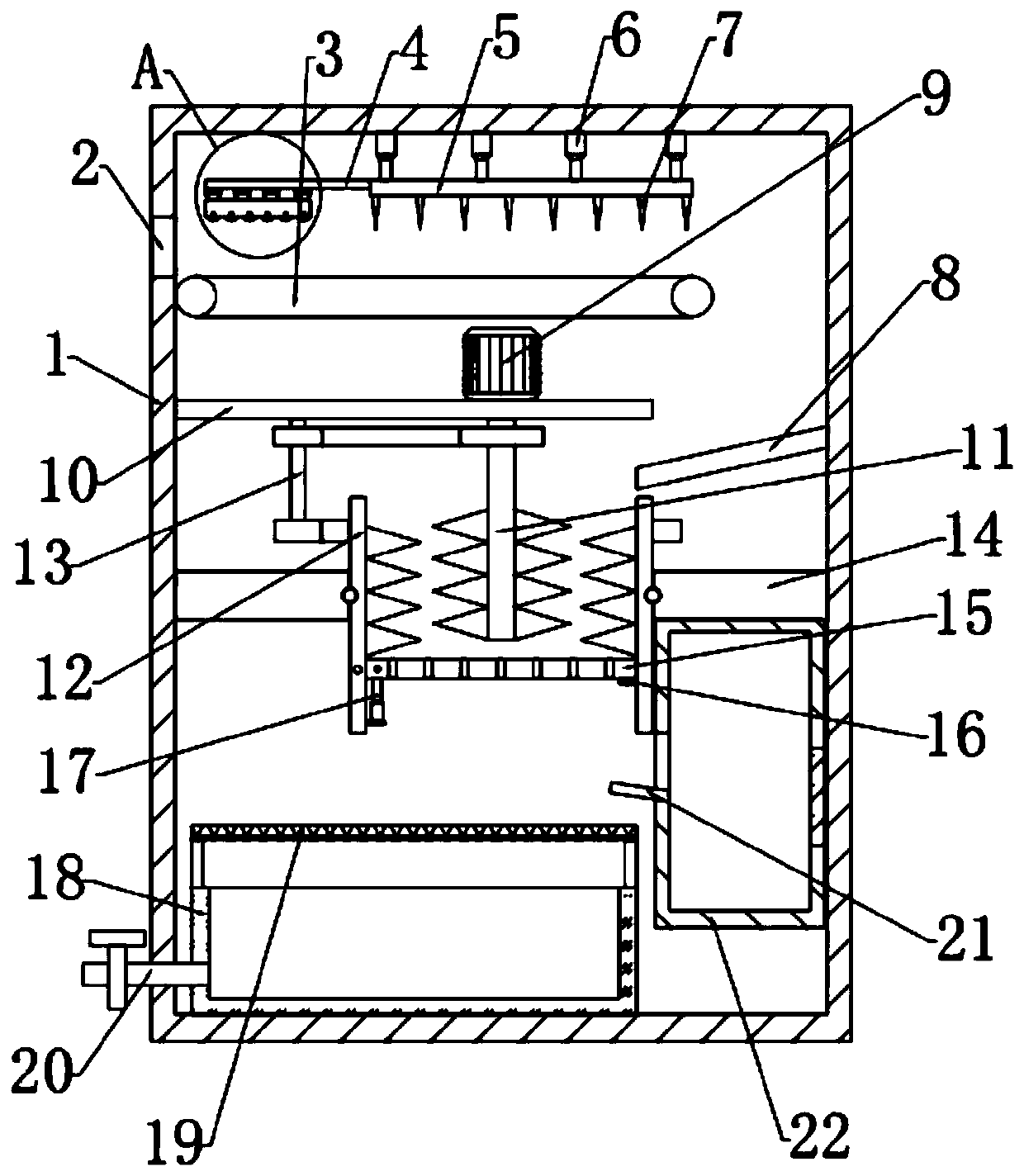

[0028] see Figure 1~2 , in an embodiment of the present invention, an agricultural sugarcane juice extractor includes a housing 1, a conveyor belt 3 is fixedly connected to the inside of the housing 1, and a feed port 2 is provided on the left side of the conveyor belt 3, and the conveyor belt 3. A material cutting mechanism is provided on the upper side. A material guide plate 8 fixedly connected to the housing 1 is provided on the lower side of the right end of the conveyor belt 3. A support plate 14 fixedly connected to the housing 1 is provided on the lower side of the material guide plate 8. , the inner bearing of the support plate 14 is connected with a crushing and squeezing mechanism, the lower side of the crushing and squeezing mechanism is provided with a liquid storage tank 18, and the right side of the liquid storage tank 18 is provided with a fixed connection with the support plate 14. The residue box 22 is fixedly connected with a baffle plate 21 on the left sid...

Embodiment 2

[0030] In this embodiment, the material cutting mechanism includes a material cutting plate 5, a first telescopic rod 6, and a cutter 7. The first telescopic rod 6 is fixedly connected between them, and several cutting knives 7 are evenly arranged on the bottom of the cutting board 5, and the cutting knives 7 are fixedly connected with the cutting board 5. By setting a cutting mechanism, the sugarcane can be cut into Several small sections are convenient for crushing sugarcane and improving the crushing effect.

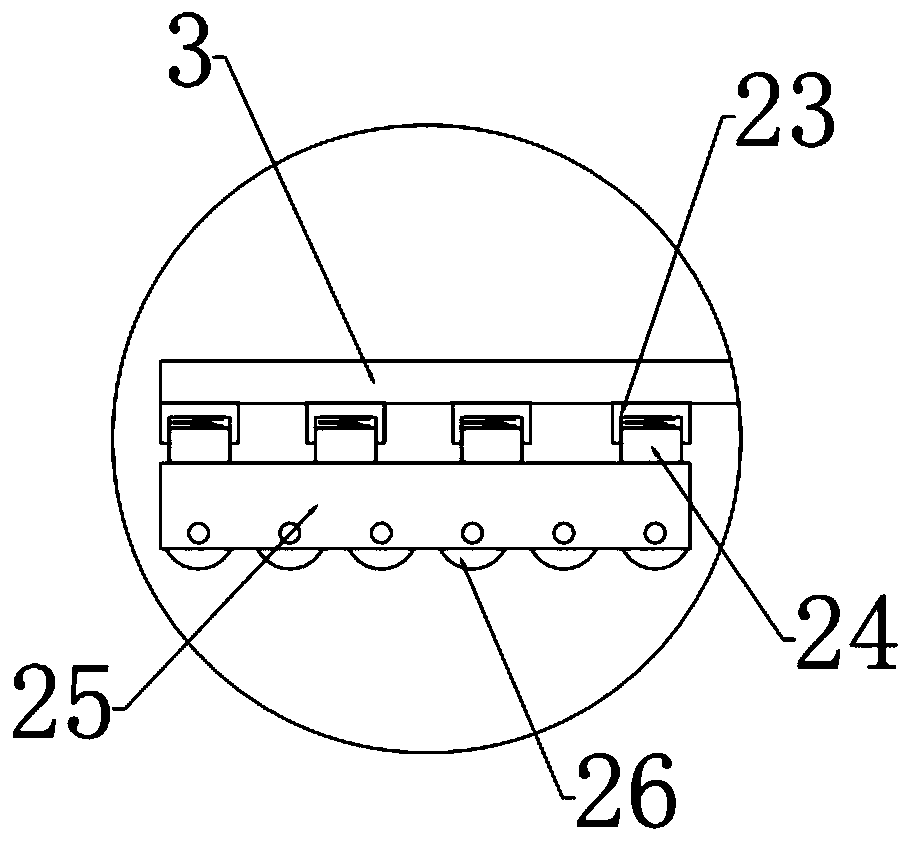

[0031] In this embodiment, the left side of the cutting plate 5 is fixedly connected with a connecting plate 4, the bottom of the connecting plate 4 is fixedly connected with a number of fixed blocks 23, and the bottom end of the fixed block 23 is slidably connected with a slider 24 , the fixed connection between the slider 24 and the fixed block 23 is provided with a spring, the bottom of the slider 24 is fixedly connected with a splint 25, and the bottom end of the ...

Embodiment 3

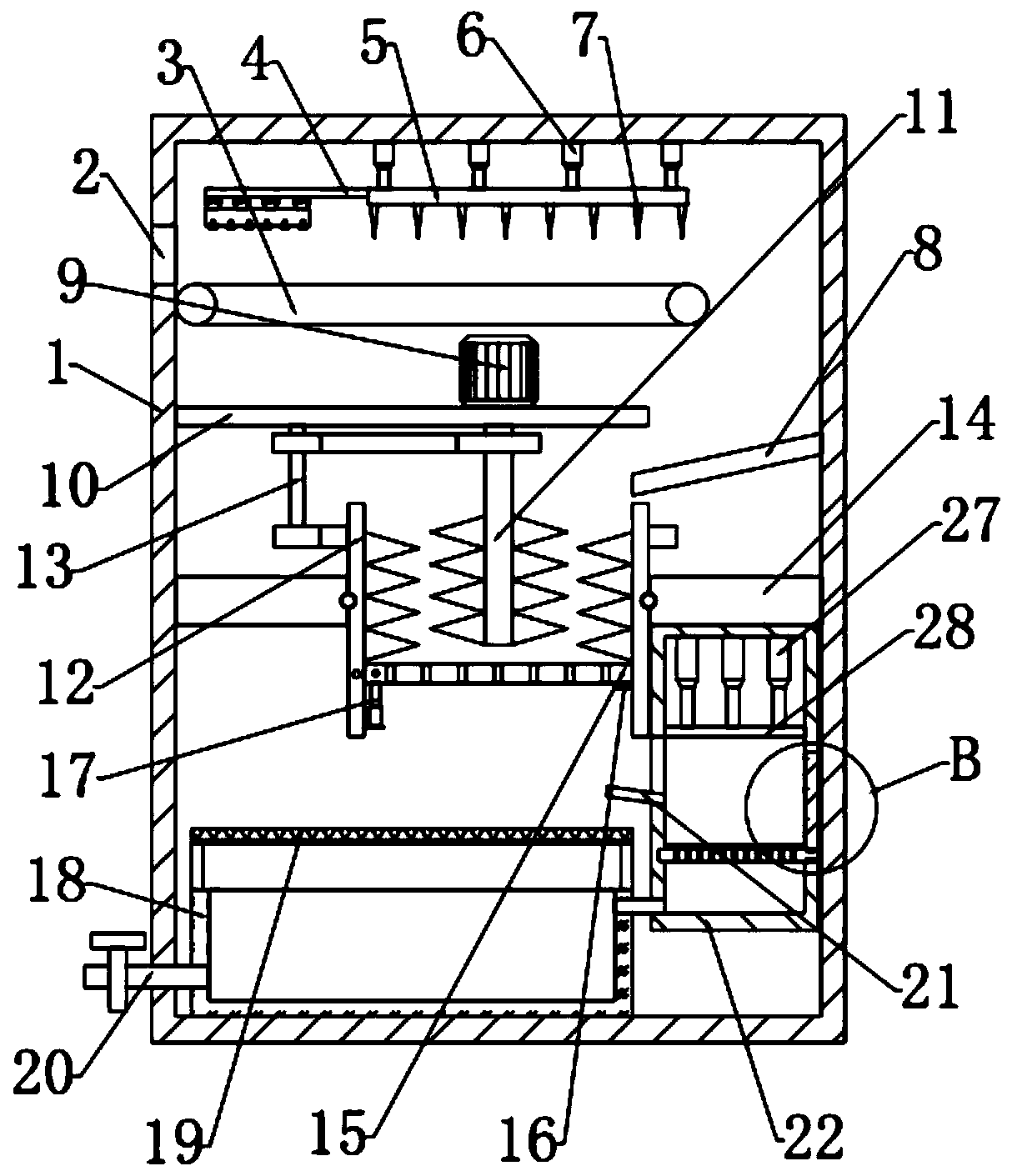

[0036] see Figure 3-4 , the difference between this embodiment and embodiment 1 is:

[0037] A squeezing mechanism is arranged in the residue box 22, and the squeezing mechanism includes a third telescopic rod 27, a pressing plate 28 and a second filter plate 31, and the third telescopic rod 27 is fixedly connected to the inside top of the residue box 22. The bottom of the third telescopic rod 27 is fixedly connected with a pressing plate 28, the lower side of the pressing plate 28 is provided with a second filter plate 31, the second filter plate 31 is clamped with the residue box 22, and the right end of the second filter plate 31 is arranged There is a groove, and a sealing ring 32 is arranged in the groove, and a box door 29 hinged with the residue box 22 is arranged on the top of the right end of the second filter plate 31. By setting the second filter plate 31 and the pressing plate 28, the residue can be The remaining sugarcane juice is extruded to make full use of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com